26 Daikin IM 696-4

Service Information

Binary Outputs—Auxiliary Control Boards (CCB1,

CCB2, GCB1, EHB1 & ERB1)

The optional auxiliary control boards include nine binary

outputs th

at control nine on-board electromechanical relays.

Unit control devices are wired to these outputs through output

terminals on the left side of the board. The functions of these

outputs vary for the different auxiliary board applications. The

following sections describe the output functions for the

auxiliary control board applications.

CCB1 and CCB2 (RPS, RFS/RCS, RDT, RPE, RDE, RCE,

RPR, and RFR)

When a unit is equipped with a factory condensing unit, each

of the two cooling circuits is controlled with an auxiliary

control board. Circuit #1 is controlled by the CCB1 and Circuit

#2 is controlled by the CCB2. There are nine binary output

relays on each cooling control board. These relays are

energized based on commands received from the MCB to

provide the appropriate switching actions in the DX cooling

control circuits.

The output relays on the CCB1 and CCB2 board control

com

pressor

contactors, compressor unloaders, circuit liquid

line solenoid valves, or condenser fan outputs. Tables 14

through 21 list the CCB1 and CCB2 output functions for the

available unit compressor staging configurations.

The liquid line solenoid valve on each circuit opens (BO4

turned on

) before the first compressor in the circuit is turned

on. Normally the compressor outputs in the circuit begin

turning on according to the controller staging logic as soon as

the circuit low pressure switch closes. The exception to this

rule is when a unit is equipped and configured for low ambient

operation. In this case the first stage compressor in a circuit is

turned on at the same time the liquid line solenoid valve is

opened.

The condenser fan outputs are turned on and off based on

amb

ient

temperature set points adjustable through the unit

keypad.

The compressor staging sequences for the available

compressor staging configurations are des

cribed in the

following sections.

2-Compressors/3-Stage. In this configuration there

are

two u

nequally sized scroll compressors and two cooling

circuits. All cooling outputs are always controlled in the same

way. There is no compressor or circuit lead/lag

operation with

this configuration.

The normal staging sequence is as follows:

When a capacity increase is required and

the cooling capacity

is 0%, the sm

all compressor in Circuit #1 is turned on. When a

further capacity increase is required, the large compressor in

Circuit #2 is turned on while the small compressor in Circuit

#1 is turned off. When a further capacity increase is required,

the small compressor in Circuit #1 is turned on while the large

compressor in Circuit #2 remains on. When capacity decrease

is required, the compressors stage off in the reverse order.

If the small compressor (Circuit #1) is disabled, the large

compres

sor (C

ircuit #2) operates when cooling is required and

the cooling capacity is set to 66%. If the large compressor is

disabled, the small compressor operates when cooling is

required and the cooling capacity is set to 33%.

Table 14 summarizes the normal binary output functions and

staging sequencing for the CCB1

and CCB2 for the

2-Comp

ressor/3-Stage cooling configuration. The “X”

characters in Ta

ble 14 indicate that the output is energized for

a particular cooling capacity.

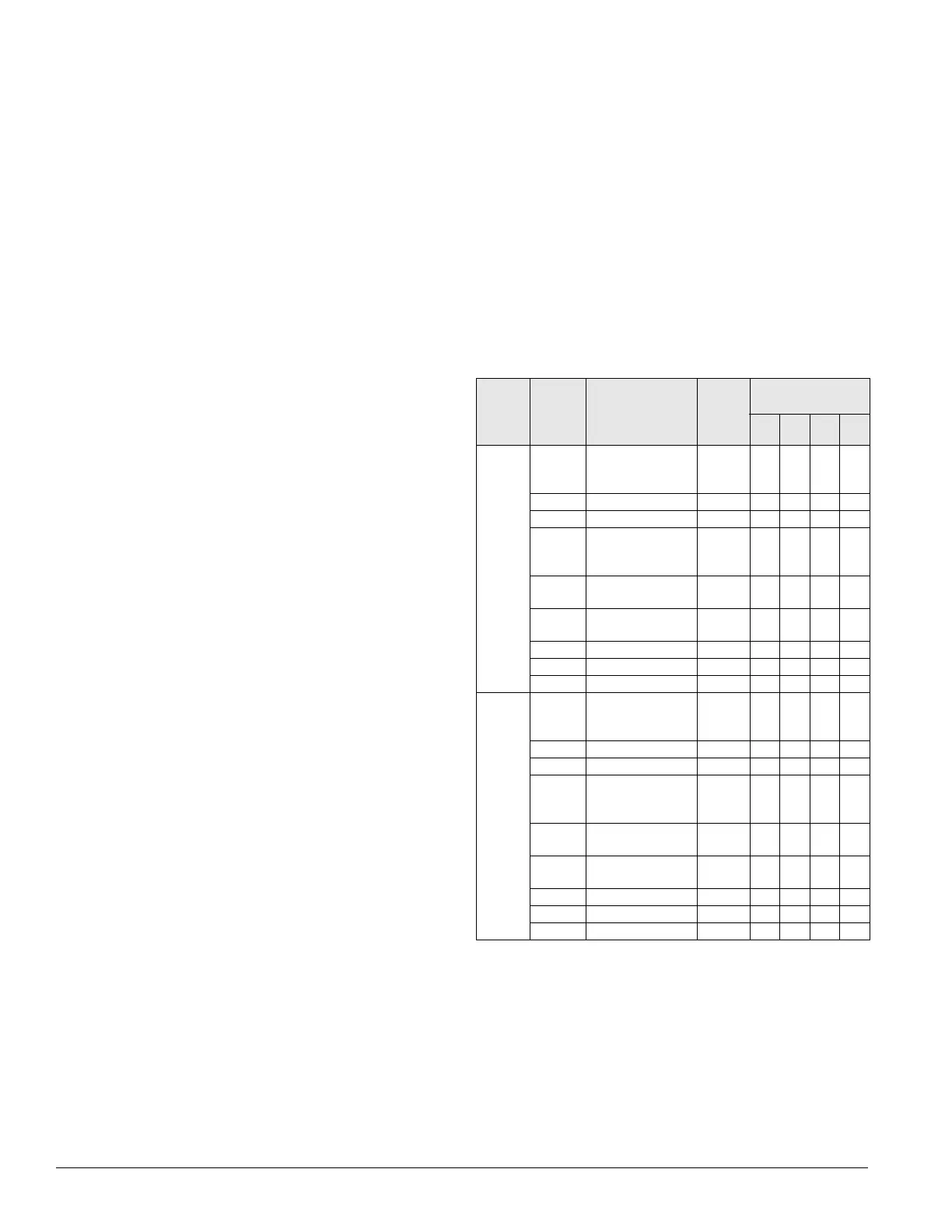

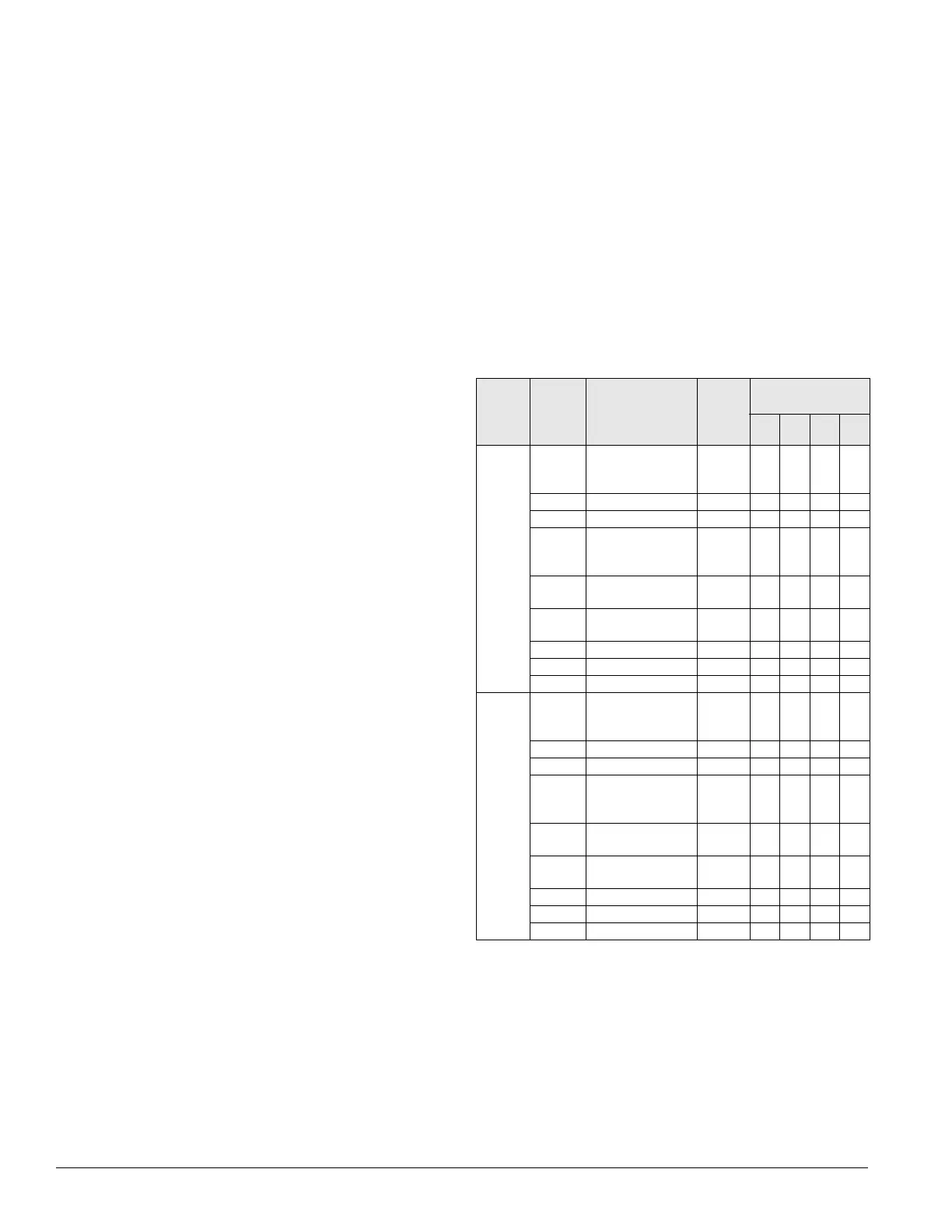

Cooling

circuit

number

Output

number

Description

Action

with

output

on

Cooling capacity

(%)

0 33 66 100

Table 14: Binary outputs for cooling control boards (CCB1

and CCB2): 2-compressors/3-stage

1

(CCB1)

BO1 Compressor #1

(small compressor)

ON/OFf

ON X X

BO2 Not used -

BO3 Not used -

BO4 Circuit # 1 liquid line

solenoid valve

open/close

a

a. Circuit Lead/Lag and Cross Circuit Loading versus Lead Circuit loading do

not apply to this staging configuration.

Open X X

BO5 Condenser fan #11

ON/OFF

ON

b

b. Condenser fan outputs turn on and off based on ambient or evaporative

condensing sump temperature set points adjustable through the unit

keypad.

c. This output is not used on unit equipped with an evaporative conden

ser

and a VFD controlling the first condenser fan on each circuit (Condenser

Fan # 11 and # 21). The VFD controlling these fans is started and stopped

and modulated via RS-485 communications with the main control board.

d. This output is used to open a sump dump valve on units equipped with an

evaporative condenser. Output is energized to open valve.

b

BO6 Condenser fan #12

ON/OFF

ON

bb

BO7 Not used -

BO8

d

Not used -

BO9 Not used -

2

(CCB2)

BO1 Compressor #2 ON/

OFF (large

compressor)

ON X X

BO2 Not used -

BO3 Not used -

BO4 Circuit #2 liquid line

solenoid valve

open/close

a

Open X X

BO5 Condenser fan # 11

ON/OFF

c

ON b b

BO6 Condenser fan # 12

ON/OFF

ON b b

BO7 Not used -

BO8

d

Not used -

BO9 Not used -

Loading...

Loading...