User manual Installation, Operation and Maintenance APP Pumps (APP 16-22)

12

180R9265 / IOM APP Pumps - v01 / 01.2013

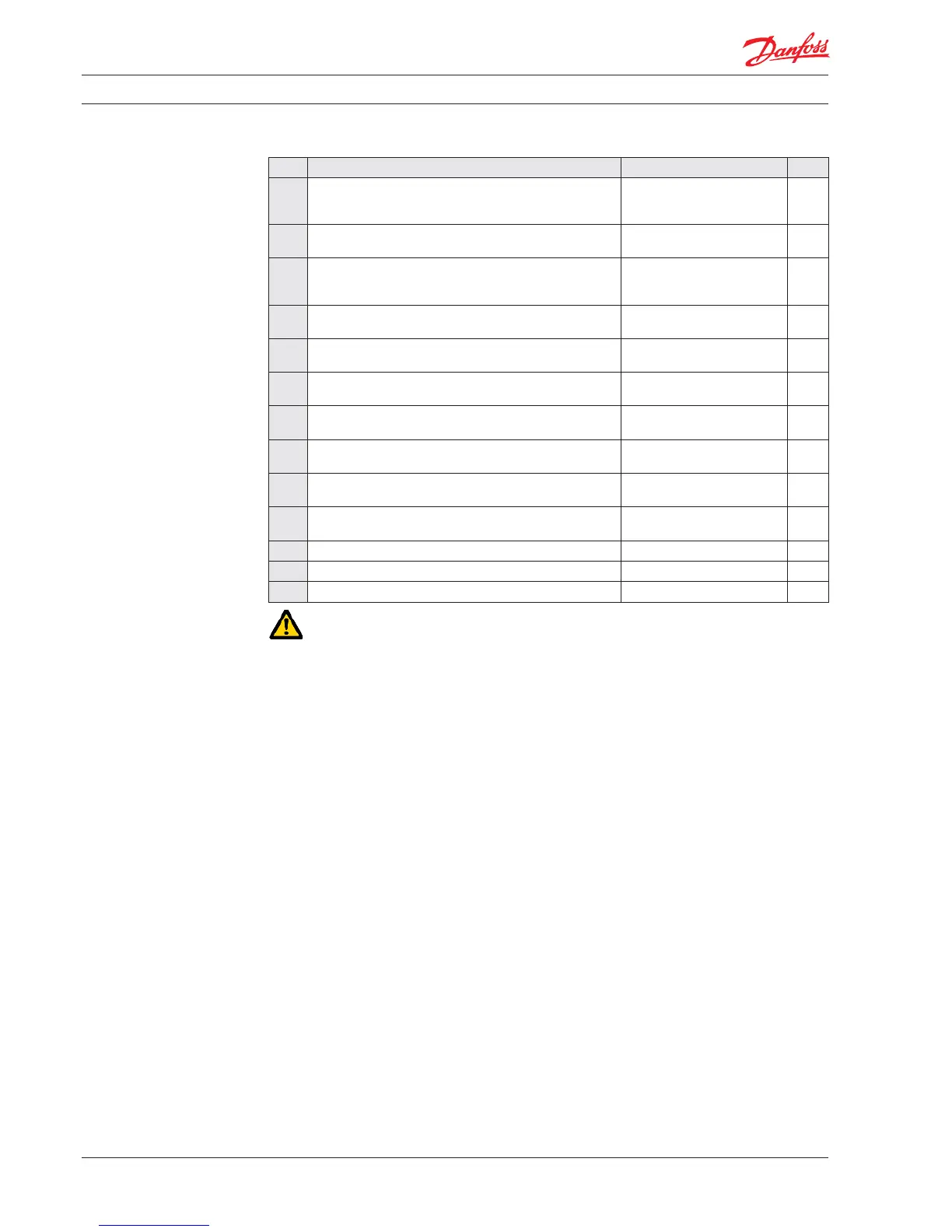

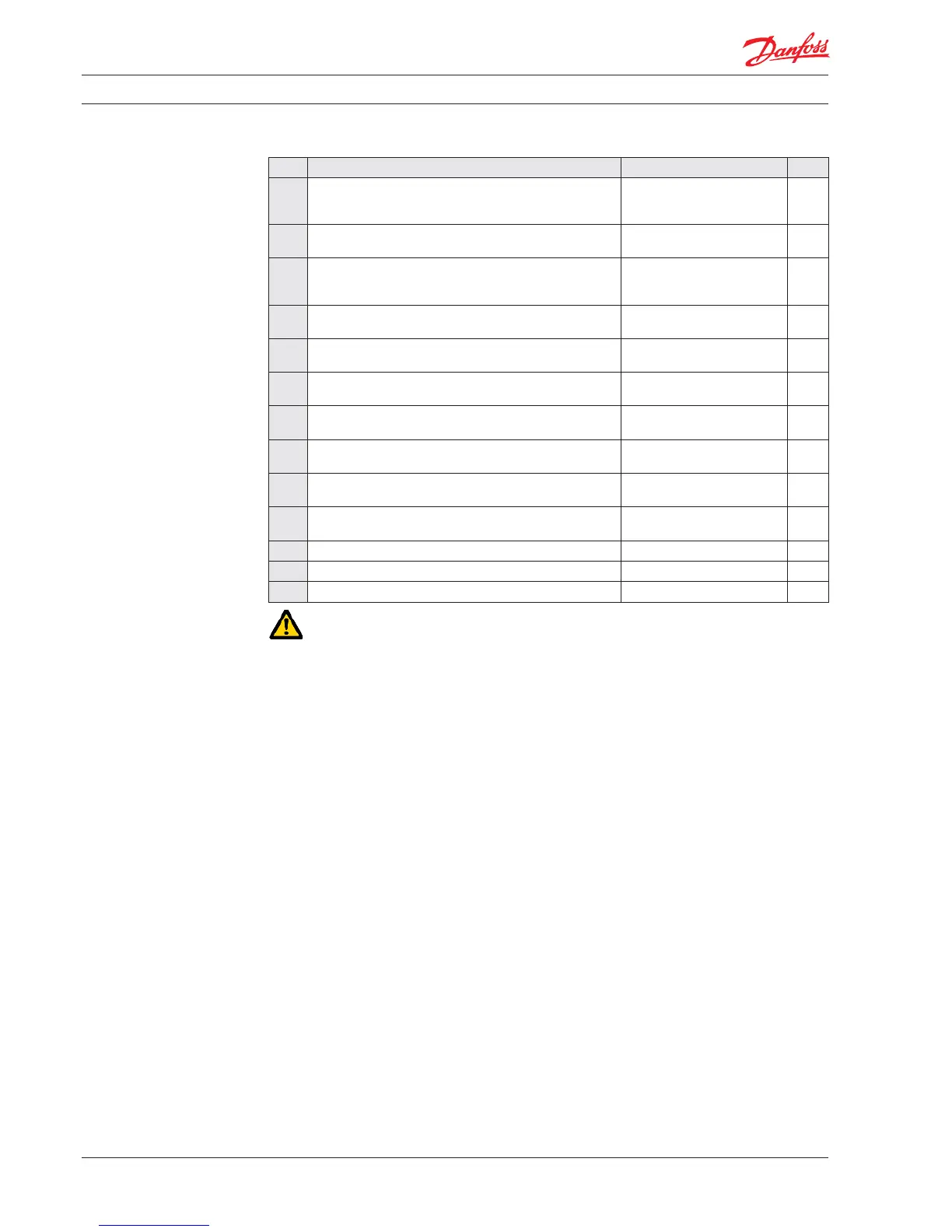

Table 1: Check points when assembling and commissioning system

Check points Comment OK ?

CP1 Ensure that the environmental conditions are safe. See Arrival inspection,

transportation, handling,

lifting and storage, chapter 4.

CP2 Minimum and maximum start-up temperature for uid and

pump.

See Data sheet or Instruction,

appendices 1 and 2.

CP3 Filtration condition (10µm absolute (ß10 = 5000) See Danfoss requirements in

Data sheet and Instruction,

appendices 1 and 2

CP4 Power supply for electric motor and VFD. See Data sheet for the used

motor and VFD, appendix 1.

CP5 Safety circuit / breaker must be sized for the motor and

environment (corrosion and humidity)

See Data sheet for the used

safety circuit.

CP6 Bolts and screws must conform to environmental conditions

as well as uid and torque requirements.

CP7 Instrumentation, pressure switch should be designed to

conform to the environment (corrosion and humidity).

See Data sheet for the used

equipment.

CP8 Check the factory settings of the safety/relief valves or

pressure relief valves (8 & 9).

See Data sheets for the used

valves.

CP9 Check the settings of the pressure transmitter/switch (3) set

at min. inlet pressure.

See Data sheet or Instruction,

appendices 1 and 2.

CP10 Check that all pressure indicators (PI) are selected to be able

to measure the system pressure range.

Scaling should at least be 1 Bar

or more precise.

CP11 Check coupling distance ( air gab – movement of the spider ) 3 – 5 mm

CP12 Check correct connections on the pump ( in & outlet)

CP13 Check piping for possible air gaps.

5.7 Lifting and positioning

Lift the pump unit onto base (Remember

vibration dampers, if needed). Fasten the motor

to the base.

See also chapter 4, Arrival inspection, transporta-

tion, handling, lifting and storage.

5.8 Mount the dierent equipment

(connections, pipes, tubes, check and safety/relief

valves, etc.)

t

The hard piping and exible hoses used must

be of proper design and must be installed in

accordance with the manufacturer’s recom-

mendations. (see also Data sheet for Hose

and hose ttings and Instruction for

Assembling Hose kit - both available on

www.ro-solutions.danfoss.com).

t Misalignment of the hard pipes may place

stress on the pump port connection and may

damage the pump.

tPrevent excessive external pipe load.

t Do not connect piping by applying external

force (use of wrenches, crane, etc.) Piping

must be aligned without residual stress.

t Do not mount expansion joints so that their

force applies internal pressure on the pump

connections.

5.9 Electrics

All electrical installation work must be carried

out by authorized personnel in accordance with

EN60204-1 and/or local regulations. (see also

Safety, chapter 2)

Mount the safety circuit breaker, turn the circuit

o and lock it in the o position.

Mount the power cable on the electric motor.

If a VFD is used, adjust the protective motor

switch/VFD to the current limits found on name

plate of the electric motor.

5.10 Instrumentation

The pressure switch/sensor should be mounted

as close to the pump as possible. It is recom-

mended to test the pressure/sensor switch via an

instrumentation manifold.

Mount the pressure switch/sensors according to

the manufacturer’s instructions.

5.11 Connections

Mount connections and maybe check valve(s).

Mount and tighten as specied.

Loading...

Loading...