29

180R9265 / IOM APP 16-22 Appendices - v02 / 01.2013

Bearing size and type are specified on the rating plate.

Motor types HMA2 and HMC2 is as standard with lifetime

greased bearing with motor size ≤225.

Motor types MS and Y2E is as standard with lifetime greased

bearing with motor size ≤160.

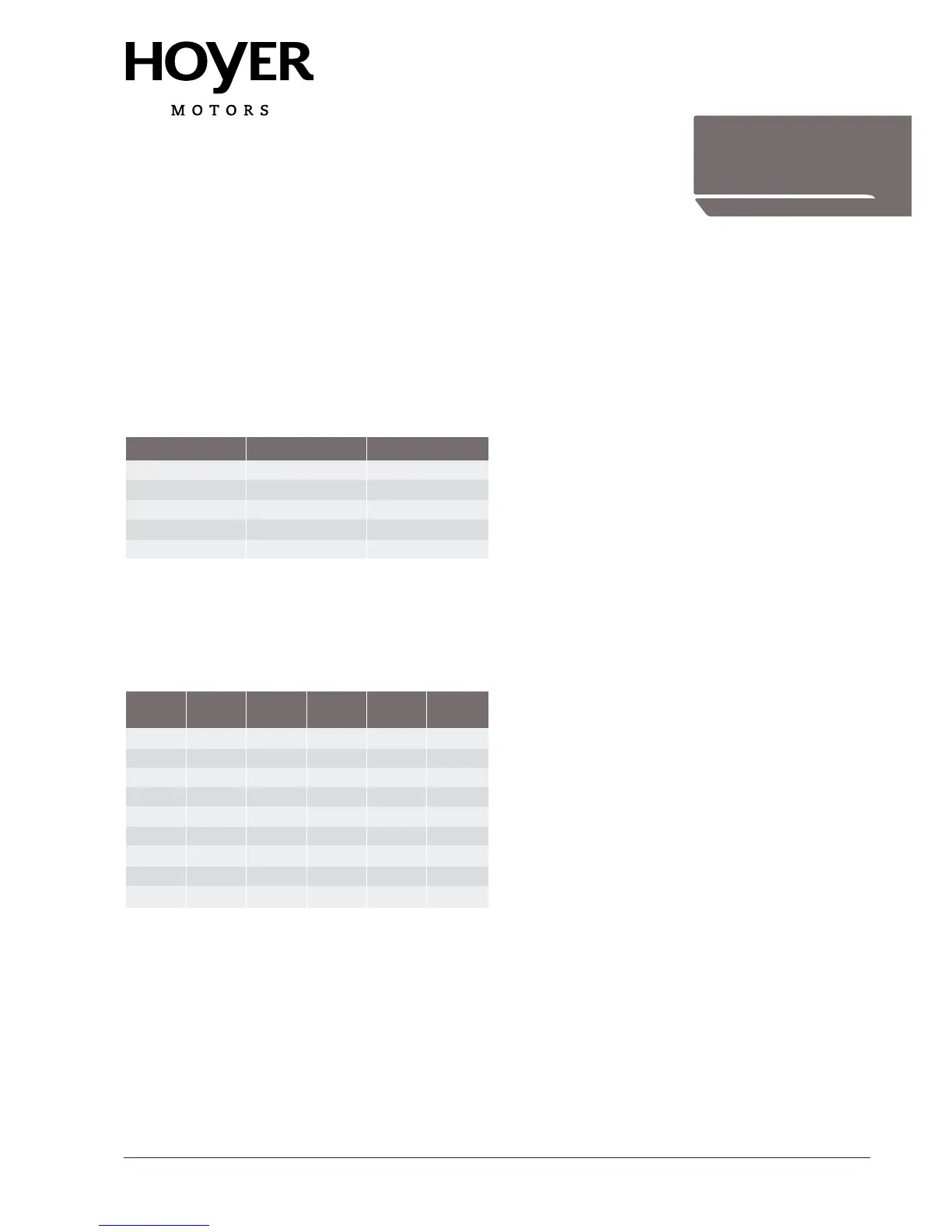

Typical duty hours for lifetime lubricated bearings.

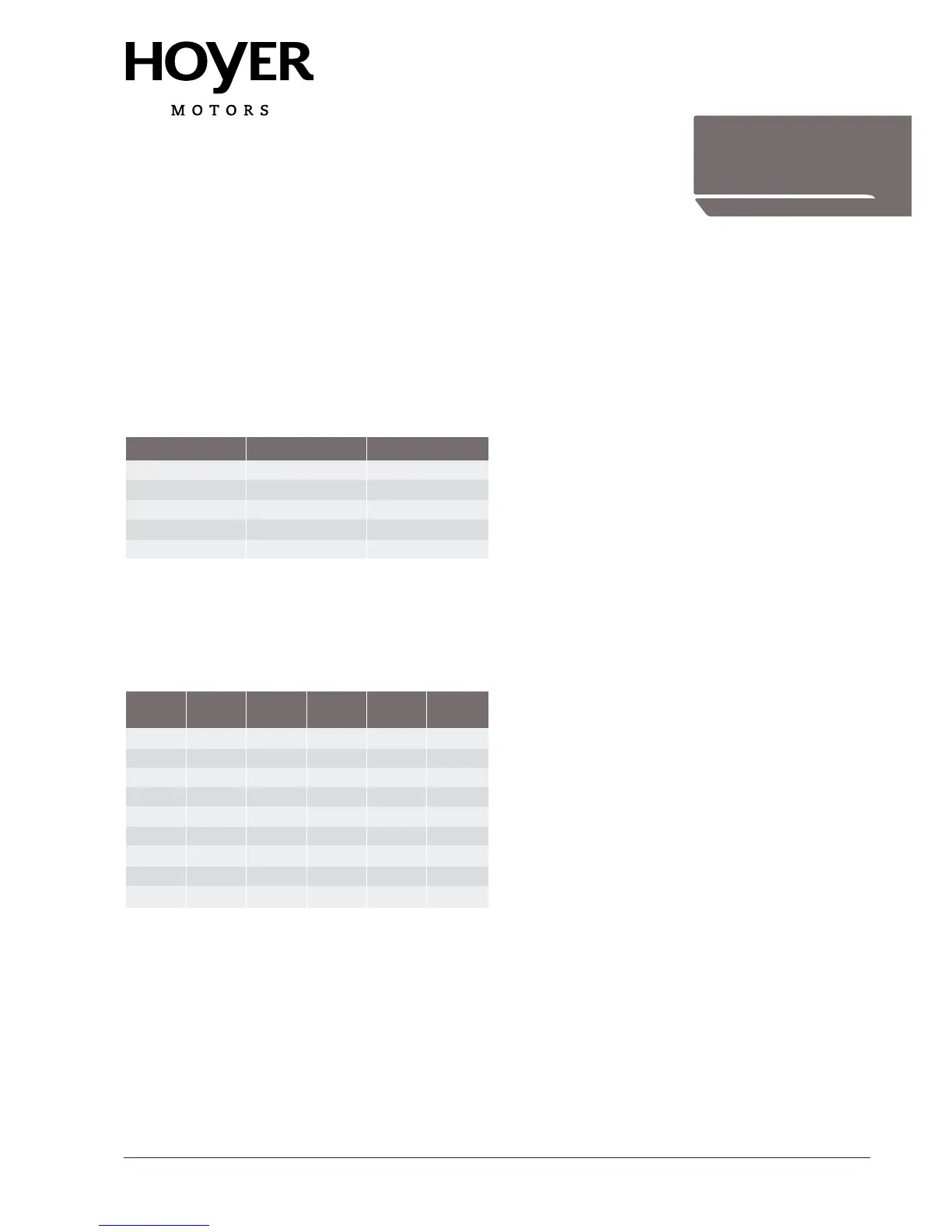

Motors with a re-greasing system must be lubricated with

high quality lithium complex grease, NLGI grade 2 or 3, with

a temperature range of between -40°C to +150°C.

Motors are normal fitted with a data plate with greasing

information; if it is missing use the following re-greasing

intervals.

Grease the motor while running, open the grease outlet plug

and let the motor run 1-2 hours before the outlet grease

plug is closed again.

Grease the motor for the first time during commissioning.

The following applies in general for both lifetime lubricated

and re-lubricated bearings:

At 60Hz the time will be reduced by app. 20%.

Data for vertically mounted motors are half of the above

values.

The table values are based on an ambient temperature of

25°C. The values must be halved for every 15K increase in

bearing temperature.

Higher speed operations, e.g. frequency converter drive will

require shorter greasing intervals. Typically, doubling the

speed will reduce the values by 50%.

6. Special note for Atex Zone 22 motors.

Notice for the use of electrical equipment in areas with

combustible dust.

Designation of motor according to EC directive:

Ex II 3D T125°C, IP55.

The dust hazardous 3-phase asynchronous motors are

in accordance with European standard EN 50281-1-1.

Combustible dust areas will be found in agricultural areas

and in industrial environments.

Only one electrical installation may be installed in one

specified area (zone).

Only certificated cable glands for category 2D may be used.

Unused glands must be closed.

Connections must be made in such a way as to ensure that

a permanently safe electrical connection is maintained,

both for the main supply and earth connection.

Installations must be in accordance with actual standards

for installation in the Zone 22 area.

It is recommended that EN 50281-2 is followed according

temperature and dust on the motor surface.

The use of motors with so much surface dust that the

motor temperature increases is not permitted.

Regularly cleaning is recommended.

The radial shaft sealing ring is part of the ATEX certification.

It is important that the ring is always intact.

The shaft sealing must be regularly checked, and if dry

it must be lubricated. It is recommended that the seal is

re-lubricated regularly.

Always use the original seal ring when replaced.

Replacing bearings also means replacing the seals.

All machines must be inspected regularly for mechanical

damage.

The user is responsible for changing parts in accordance

with the lifetime of parts, in particular:

bearings, grease and lubrication of shaft sealing.

Maintenance, repairs and replacement on zone 22 motors

must only be carried out by qualified specialists.

Frame size Poles Typical lifetime

56 – 160 2 – 8 40.000h

180 2 35.000h

200 2 27.000h

225 2 23.000h

180 – 225 4 – 8 40.000h

Frame Grease 2 pole 4 pole 6 pole 8 pole

size (g) (h) (h) (h) (h)

160 20 4200 7000 8500 8500

180 20 4200 7000 8500 8500

200 25 3100 6500 8500 8500

225 25 3100 6500 8500 8500

250 35 2000 6000 7000 7000

280 35 2000 6000 7000 7000

315 50 1500 5500 6500 6500

355 60 1000 4000 5000 6000

400 80 800 3000 4000 6000

Motor Manual

Loading...

Loading...