12

180R9265 / IOM APP 16-22 Appendices - v02 / 01.2013

Data sheet APP 16-22

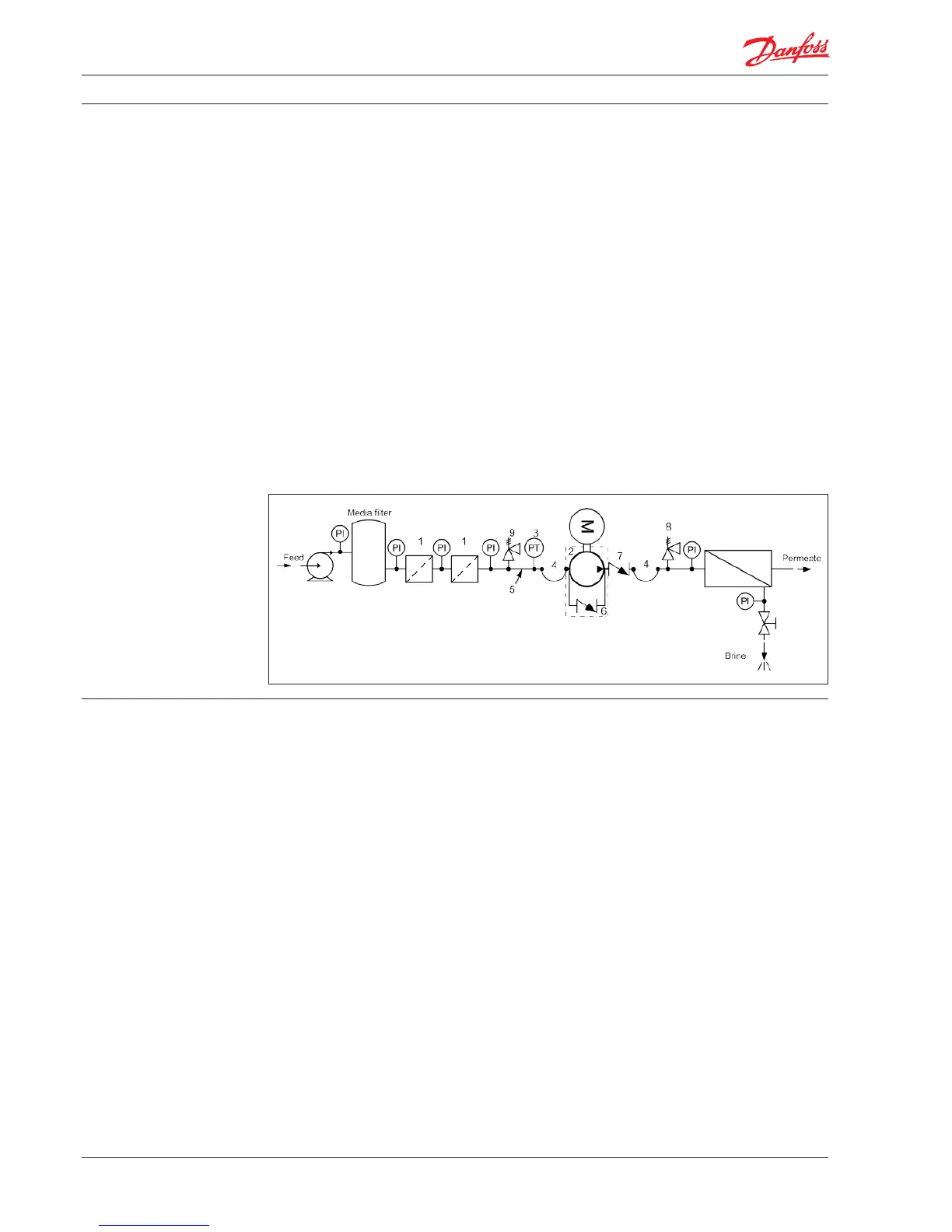

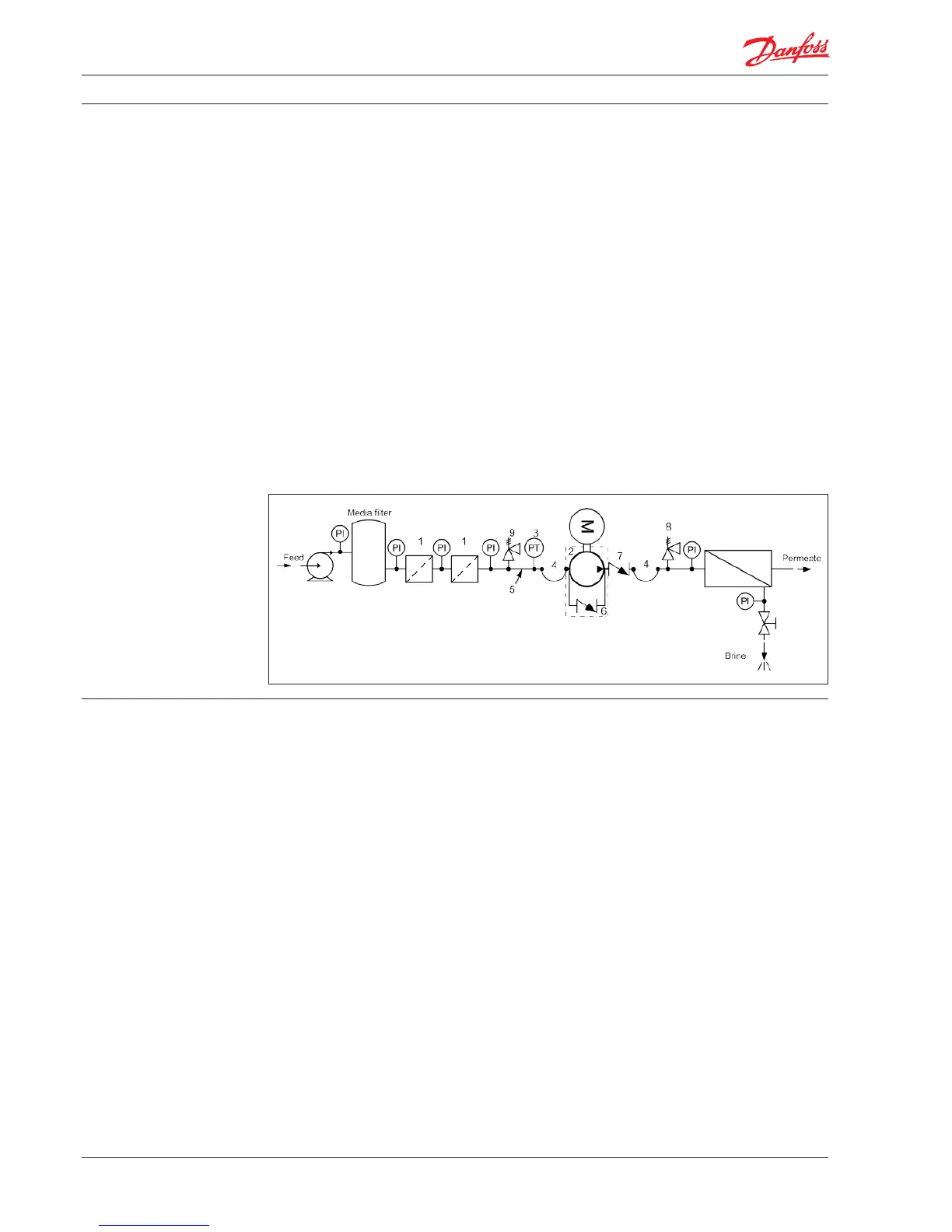

13.3 RO system with APP pump

1. Dimension the inlet line to obtain mini-

mum pressure loss (large ow, minimum

pipe length, minimum number of bends/

connections, and ttings with small

pressure losses).

2. Place an inlet lter (1) in front of the APP

pump (2). Please consult section 10,

“Filtration” for guidance on how to select

the right lter. Thoroughly clean pipes and

ush system prior to start-up.

3. Place a monitoring pressure switch (3) set

at min. inlet pressure between lter and

pump inlet. The monitoring switch must

stop the pump at pressures lower than

minimum pressure.

4. Use exible hoses (4) to minimize vibrations

and noise.

5. In order to eliminate the risk of damage

and cavitation, a positive pressure at the

inlet (5) is always to be maintained at min.

inlet pressure and max. inlet pressure.

Recommend to install safety valve or a

pressure relief valve (9) in order to avoid

high pressure peaks in case the pump stops

momen tarilly or spinning backwards.

6. For easy system bleeding and ushing, a

bypass non-return vavle (6) is integrated in

the APP pump.

7. A non-return valve (7) in outlet can be

installed in order to avoid backspin of the

pump. The volume of water in the mem-

brane vessel works as an accumulator and

will send ow backwards in case of the

pump stops momentarily.

8. A safety valve or a pressure relief valve (8)

can be installed in order to avoid system

damage as the Danfoss APP pump creates

pressure and ow immediately after

start-up, regardless of any counterpressure.

Note: If a non return valve is mounted in the

inlet line, a low pressure relief valve is also

required between non return valve and pump

as protection against high pressure peaks.

14. Service 14.1 Warranty

Danfoss APP pumps are designed for long

operation, low maintenance and reduced

lifecycle costs.

Provided that the pump has been running

according to the Danfoss specications, Danfoss

guarantees 8,000 hours service-free operation,

however, max. 18 months from date of produc-

tion.

If Danfoss recommendations concerning

system-design are not followed, it will strongly

inuence the life of the APP pumps.

14.2 Maintenance

After 8,000 hours of operation it is strongly

recommended to inspect the pump and

change any worn parts, e.g. pistons and shaft

seal. This is done in order to prevent a potential

breakdown of the pump.

If the parts are not replaced, more frequent

inspection is recommended according to our

guidelines.

Pump shutdown:

The APP pumps are made of Duplex/Super

Duplex materials with excellent corrosion

properties. It is, however, always recommended

to ush the pump with freshwater when the

system is shut down.

14.3 Repair

In case of irregular function of the APP, please

contact the Danfoss RO Solutions Sales

Organisation.

Loading...

Loading...