180R9346 | AQ240486503020en-001702 | 7© Danfoss | 2023.03

Operation guide Installation, Operation and Maintenance APP 53-92 pumps

3.1 Approved applications and operational

limits for the pumps

The pump and the pump units are designed for

the use in a Sea Water Reverse Osmosis (SWRO)

or Brackish Water Reverse Osmosis (BWRO)

systems.

The APP pumps must not be used for other

purposes than those recommended and

specied without rst consulting your local

pump distributor.

Use of the pump in other applications not

suitable for the pump unit can cause damages

to the pump unit, with risk of personal injury.

For system integration of the pump, please see

appendix 1, Data sheet and appendix 2,

Instruction.

3. Technical data

3.2 Application range

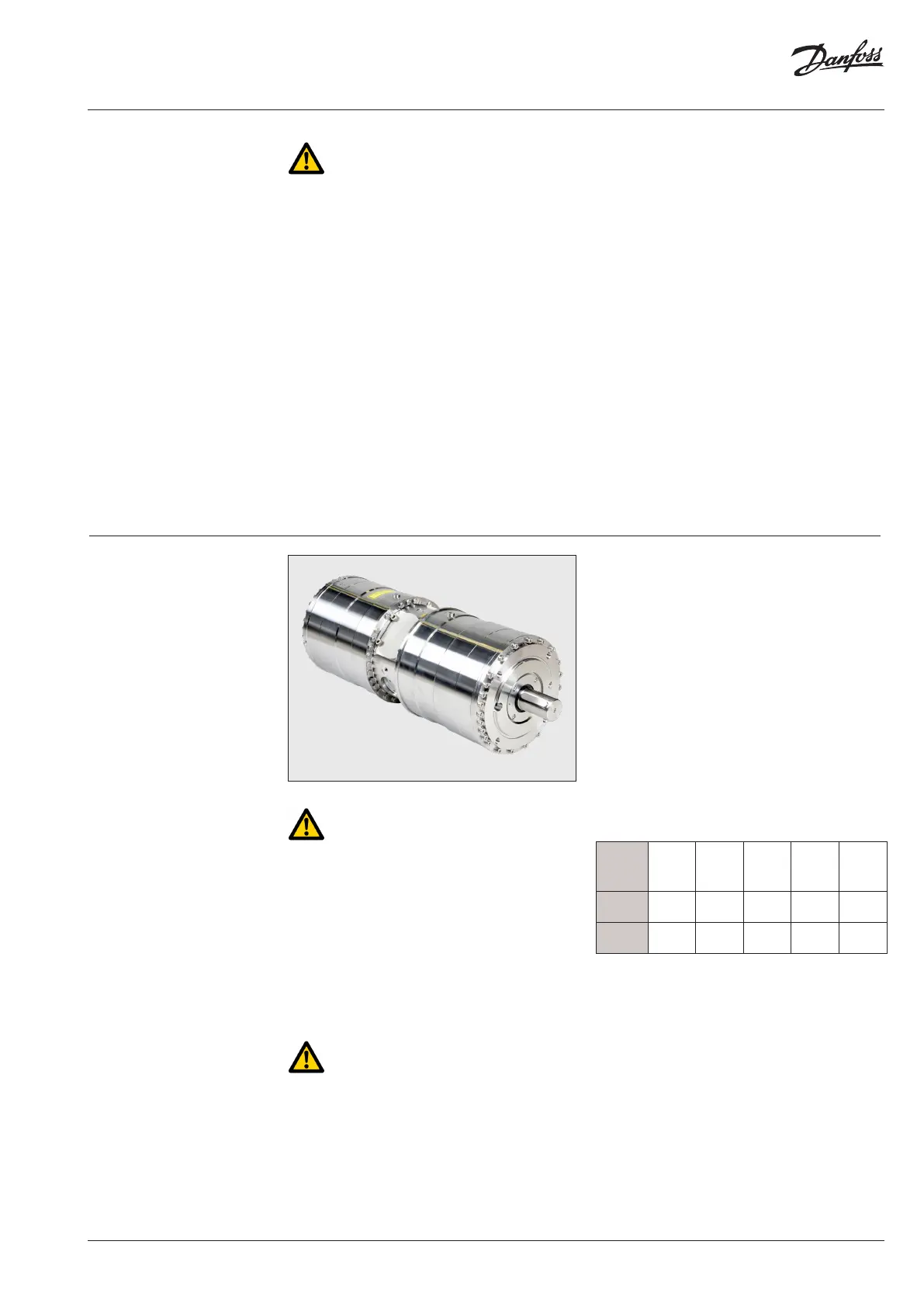

The Danfoss range of APP high-pressure pumps

is designed according to EN 809 for use in RO

applications with low viscosity and corrosive

uids such as sea water.

3.3 Electric motor data

See recommended motor in appendix 1, Data

sheet or appendix 3, IOM for motors. The motors

mentioned are the most common used motors

by Danfoss High Pressure Pumps.

3.4 VFD and Direct on line

Danfoss APP pumps can be used with VFD and

direct on line.

Torque limits can be found in the table below:

Nm APP

53

APP

65

APP

78

APP

86

APP

92

MAWT 878 1,118 1,257 1,112 1,112

MAST 1,700 1,700 1,700 1,700 1,700

MAWT: Maximum allowable working torque

MAST: Maximum allowable starting torque

3.5 Noise and vibration

Noise level for a pump unit with a ”standard”

motor measured according to EN ISO 3744: 2010,

see appendix 1, Data sheet. Possibilities to

reduce noise and vibration are described in the

same Data sheet.

3.6 Dimension drawings

Dimensions of the dierent pumps can be found

in appendix 1, Data sheet.

It is always the system builder´s responsibility

that the system design does not cause any kind

of hazard and is adapted to local regulations and

standards.

Proper installation, proper start up and shut-

down devices as well as high-pressure protection

equipment is essential.

2.3 Commissioning and servicing the unit

It is recommended that commissioning and

servicing are carried out by a minimum of two

people, where one is acting as a supervisor.

2.4 Adhere to the following important

points

• Before using the pump/pump unit it is very

important to read and understand this user

manual.

• Do not try to lift the pump unit manually;

most of the pumps weigh more than

20 kilos, see specic weight for the pump

in the appendix 1, Data sheet.

• Always bleed the pump prior to initial

start-up.

• Do not mount the pump without the bell

housing and a exible coupling.

• Do not try to start the unit before the

system components are mounted, bleeded

and adjusted.

• Flush the system throughly before

connecting the pump or pump unit.

• Check rotation direction of the motor

before mounting the pump.

2.5 In case of doubt

Please contact Danfoss A/S in case of doubt.

Contact information is listed in section 1.3,

Manufacturer and customer service address.

Loading...

Loading...