System design recommendations

Refrigerant charge limit Danfoss SM / SY / SZ compressors can tolerate

liquid refrigerant up to a certain extend

without major problems. However, excessive

liquid refrigerant in the compressor is always

unfavorable for service life. Besides, the

installation cooling capacity may be reduced

because of the evaporation taking place in the

compressor and/or the suction line instead of the

evaporator. System design must be such that the

amount of liquid refrigerant in the compressor

is limited. In this respect, follow the guidelines

given in the section: “essential piping design

recommendations” in priority.

Use the tables below to quickly evaluate the

required compressor protection in relation with

the system charge and the application.

More detailed information can be found in the paragraphs hereafter. Please contact Danfoss

Technical Support for any deviation from these guidelines.

O-cycle migration O-cycle refrigerant migration is likely to occur

when the compressor is located at the coldest

part of the installation, when the system uses

a bleed-type expansion device, or if liquid is

allowed to migrate from the evaporator into

the compressor sump by gravity. If too much

liquid refrigerant accumulates in the sump it

will saturate the oil and lead to a ooded start:

when the compressor starts running again,

the refrigerant evaporates abruptly under the

sudden decrease of the bottom shell pressure,

causing the oil to foam. In extreme situations,

this might result in liquid slugging (liquid

entering the scroll elements), which must be

avoided as it causes irreversible damage to the

compressor.

Danfoss SM/SZ/SY scroll compressors can

tolerate occasional ooded starts as long as

the total system charge does not exceed the

maximum compressor refrigerant charge.

A suitable test to evaluate the risk of o-cycle

migration is the following:

• Stabilize the non running system at 41°F

ambient temperature,

• Raise the ambient temperature to 68°F and

keep it for 10 minutes,

• Start the compressor and monitor sump

temperature, sight glass indication and sound

level.

The presence of liquid in the crankcase can be

easily detected by checking the sump level

through the oil sight glass. Foam in the oil sump

indicates a ooded start.

A noisy start, oil loss from the sump and sump

cool down are indications for migration.

Depending on the amount of migration graduate

measures shall be taken:

• Sump heater

• Liquid line solenoid valve

• Pump down cycle

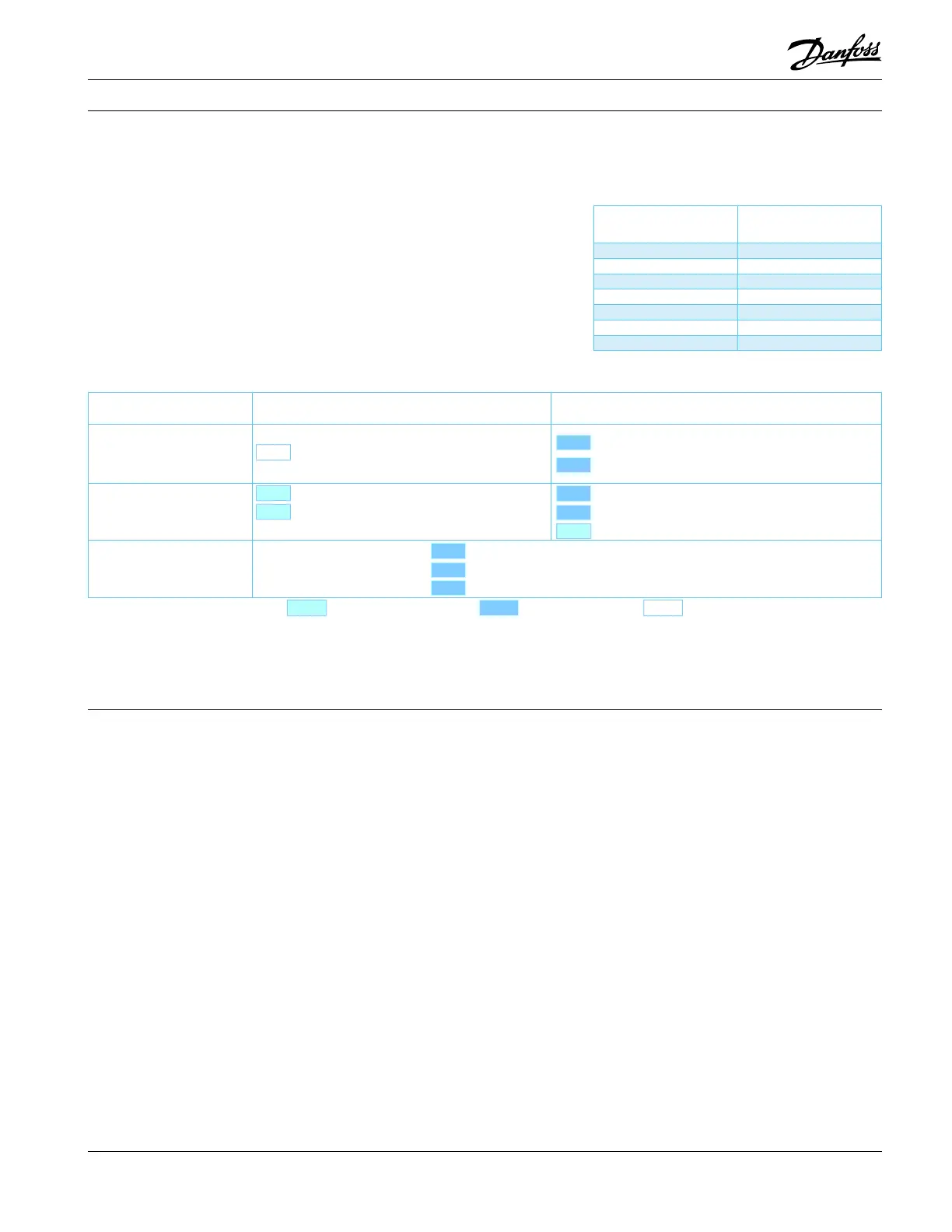

REQREC

BELOW charge limit ABOVE charge limit

Cooling only systems,

Packaged units

No test or additional safeties required

Refrigerant migration & oodback test

Sump heater

Cooling only systems

with remote condensor

and split system units

Refrigerant migration & oodback test

Crankcase heater, because full system

charge is not denable (risk of overcharging)

Refrigerant migration & oodback test

Sump heater

Liquid receiver (in association with LLSV & pump down)

Reversible heat pump system

Specic tests for repetitive oodback

Sump heater

Defrost test For more details refer to section "Reversible heat pump system.

Recommended Required No test or additional safeties required

Note: for special conditions such as low ambient temperature, low refrigerant load or brazed plate heat exchangers please refer

to corresponding section "Specic application recommendations".

REC

REC

REQ

REQ

REQ

REQ

REQ

REQ

REQ

REC

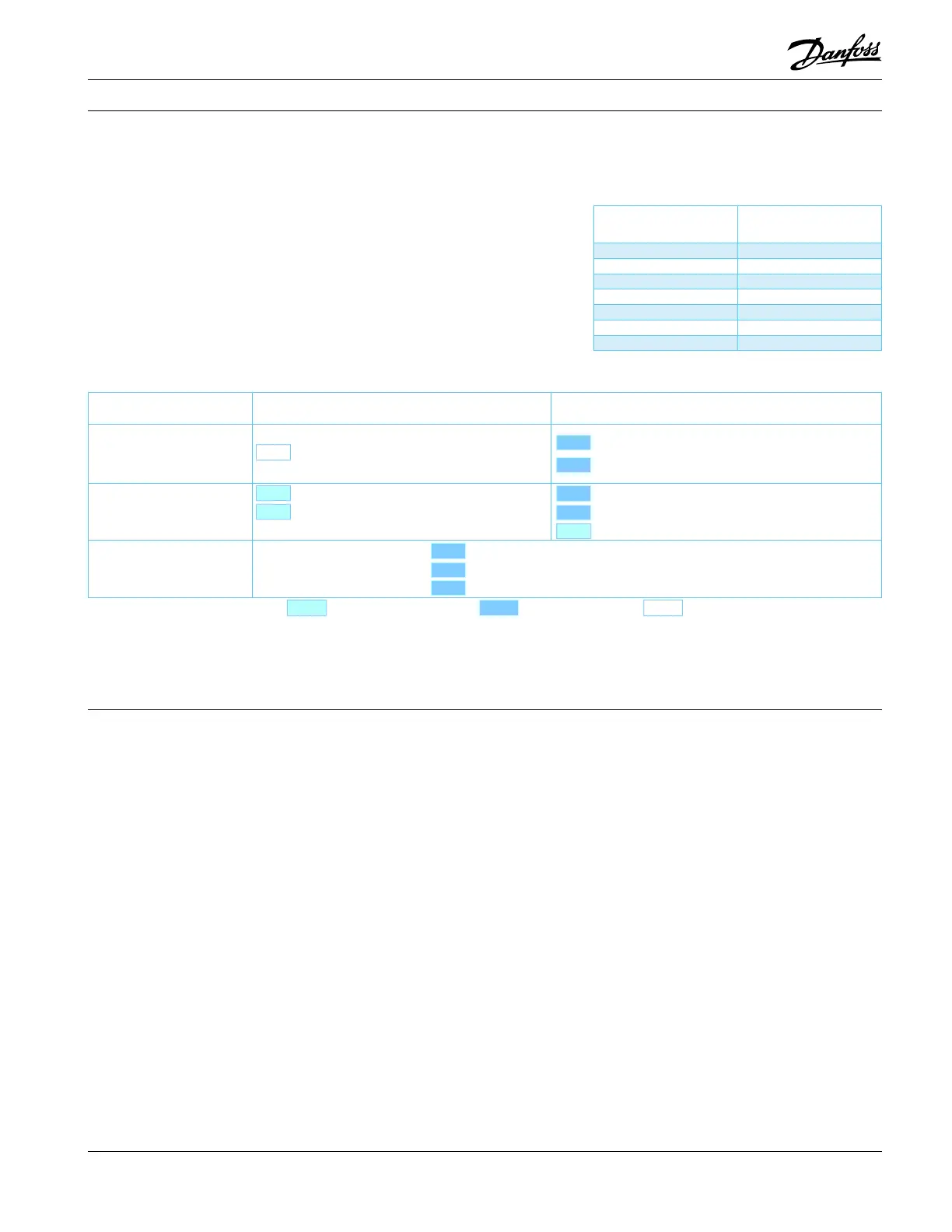

Compressor models

Refrigerant charge limit

(lbs)

S 084-090-100 19

S 110-120 22

S 112-124-147 17

S 148-161 28

S 175-185 30

S 240 35

S 300-380 44

33

FRCC.PC.003.A5.22

Application guidelines

Loading...

Loading...