Sump heaters

Sump heaters are strongly recommended on

all systems where the compressor is exposed to

low ambient temperatures, especially split and

remote condenser installations. The sump heater

will minimize refrigerant migration caused by

the large temperature gradient between the

compressor and the remainder of the system,

please refer to section "O-cycle migration".

Specic application recommendations

Brazed plate heat

exchangers

A brazed plate heat exchanger needs very little

internal volume to satisfy the set of heat transfer

requirements. Consequently, the heat exchanger

oers very little internal volume for the

compressor to draw vapor from on the suction

side. The compressor can then quickly enter into

a vacuum condition; it is therefore important

that the expansion device be sized correctly

and that a sucient pressure dierential across

the expansion device be available to ensure

adequate refrigerant feed into the evaporator.

This aspect is of special concern when operating

the unit under low ambient and load conditions.

For further information on these conditions,

please refer to the previous sections.

Due to the small volume of the brazed plate heat

exchanger, no pump-down cycle is normally

required. The suction line running from the heat

exchanger to the compressor must be trapped to

avoid refrigerant migration to the compressor.

When using a brazed plate heat exchanger as

the condensing coil, a sucient free volume for

the discharge gas to accumulate is required in

order to avoid excess pressure buildup. At least 1

meter of discharge line is necessary to generate

this volume. To help reduce the gas volume

immediately after start-up even further, the

supply of cooling water to the heat exchanger

may be opened before the compressor starts

up so as to remove superheat and condense the

incoming discharge gas more quickly.

Reversible heat pump

systems

Transients are likely to occur in reversible heat

pump systems, i.e. a changeover cycle from

cooling to heating, defrost or low-load short

cycles. These transient modes of operation

may lead to liquid refrigerant carryover (or

oodback) or excessively wet refrigerant return

conditions. As such, reversible cycle applications

require specic precautions for ensuring a long

compressor life and satisfactory operating

characteristics. Regardless of the refrigerant

charge in the system, specic tests for repetitive

oodback are required to conrm whether

or not a suction accumulator needs to be

installed. A crankcase heater and discharge gas

thermostat are required for reversible heat pump

applications.

The following considerations cover the most

important issues when dealing with common

applications. Each application design however

should be thoroughly tested to ensure

acceptable operating characteristics.

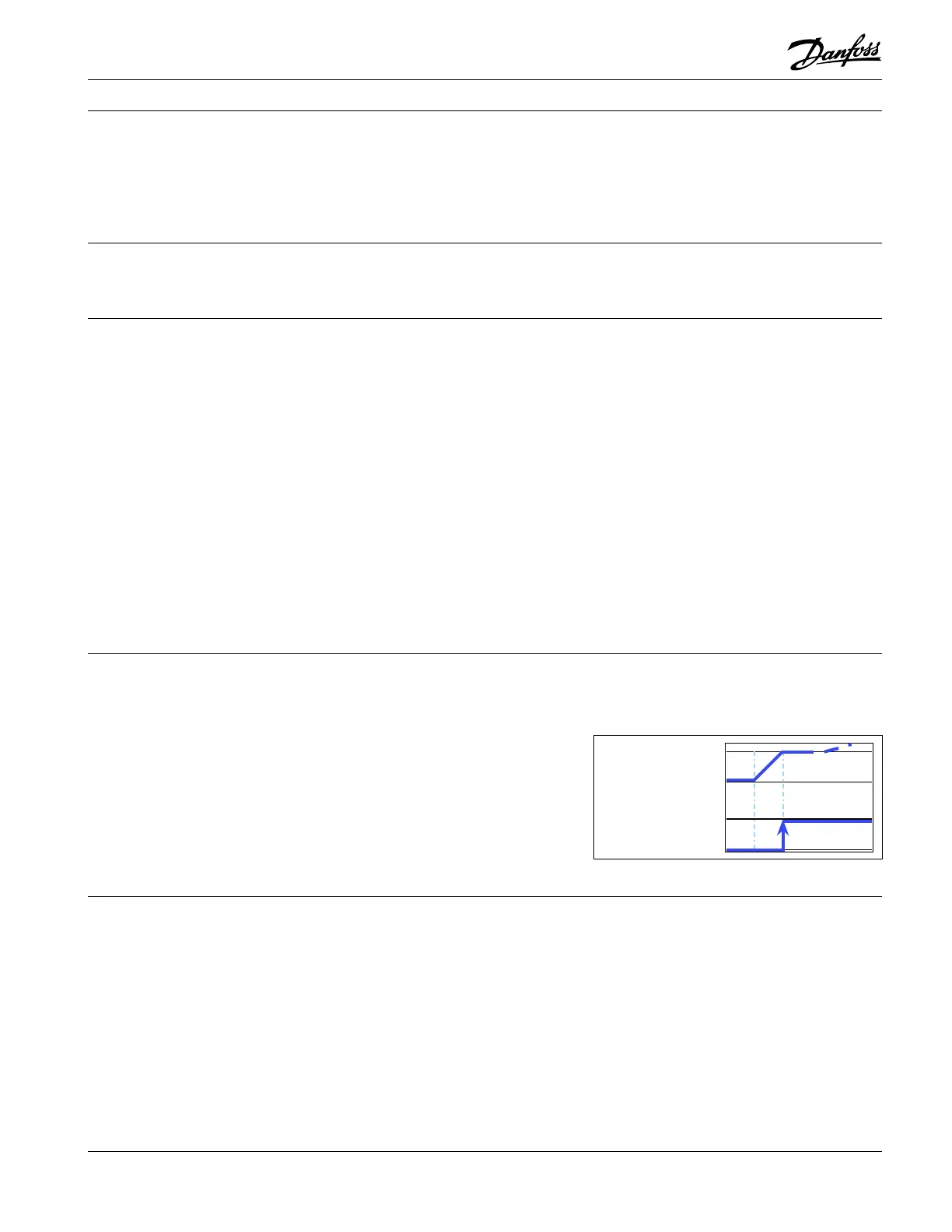

Electronic expansion valve The use of an electronic expansion valve requires

a specic compressor start / stop control.

A specific compressor start sequence control has

to be set when an electronic expansion valve

(EXV) is used. The sequence must be adjusted

according to the EXV step motor speed to allow

time for the EXV to open before the compressor

starts to avoid running under vacuum conditions.

The EXV should be closed at compressor stop

not to let refrigerant in liquid phase entering the

compressor. Ensure that the EXV closes when the

supply voltage to the controller is interrupted (ie

power cut o) by the use of a battery back up.

The compressors should be run for a

minimum period in order to ensure that the

oil has sucient time to properly return to the

compressor sumps and that the motor has

sucient time to cool under conditions of lowest

refrigerant mass ows.

Low load operations

EXV Opened

Closed

Compressor On

O

37

FRCC.PC.003.A5.22

Application guidelines

Loading...

Loading...