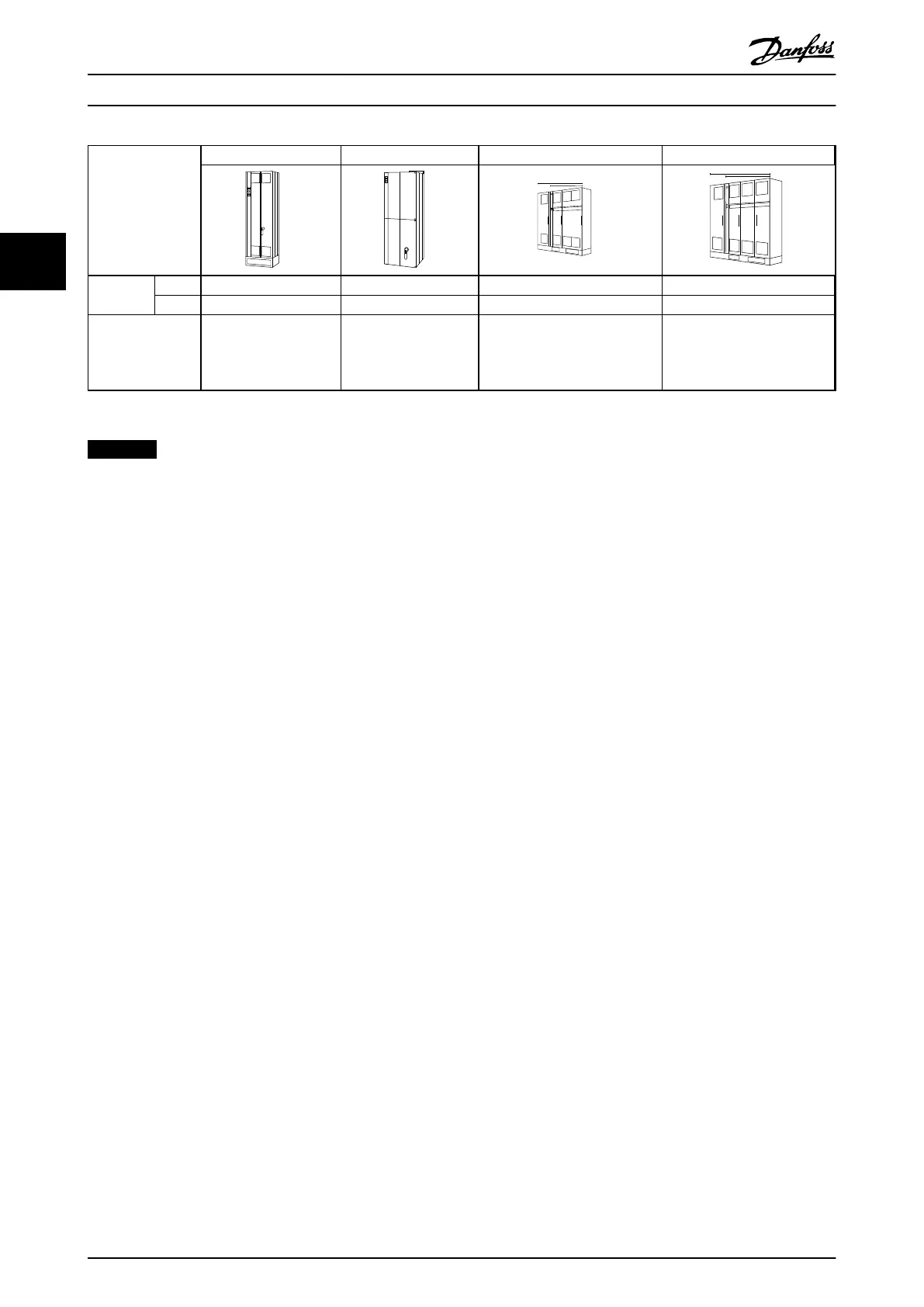

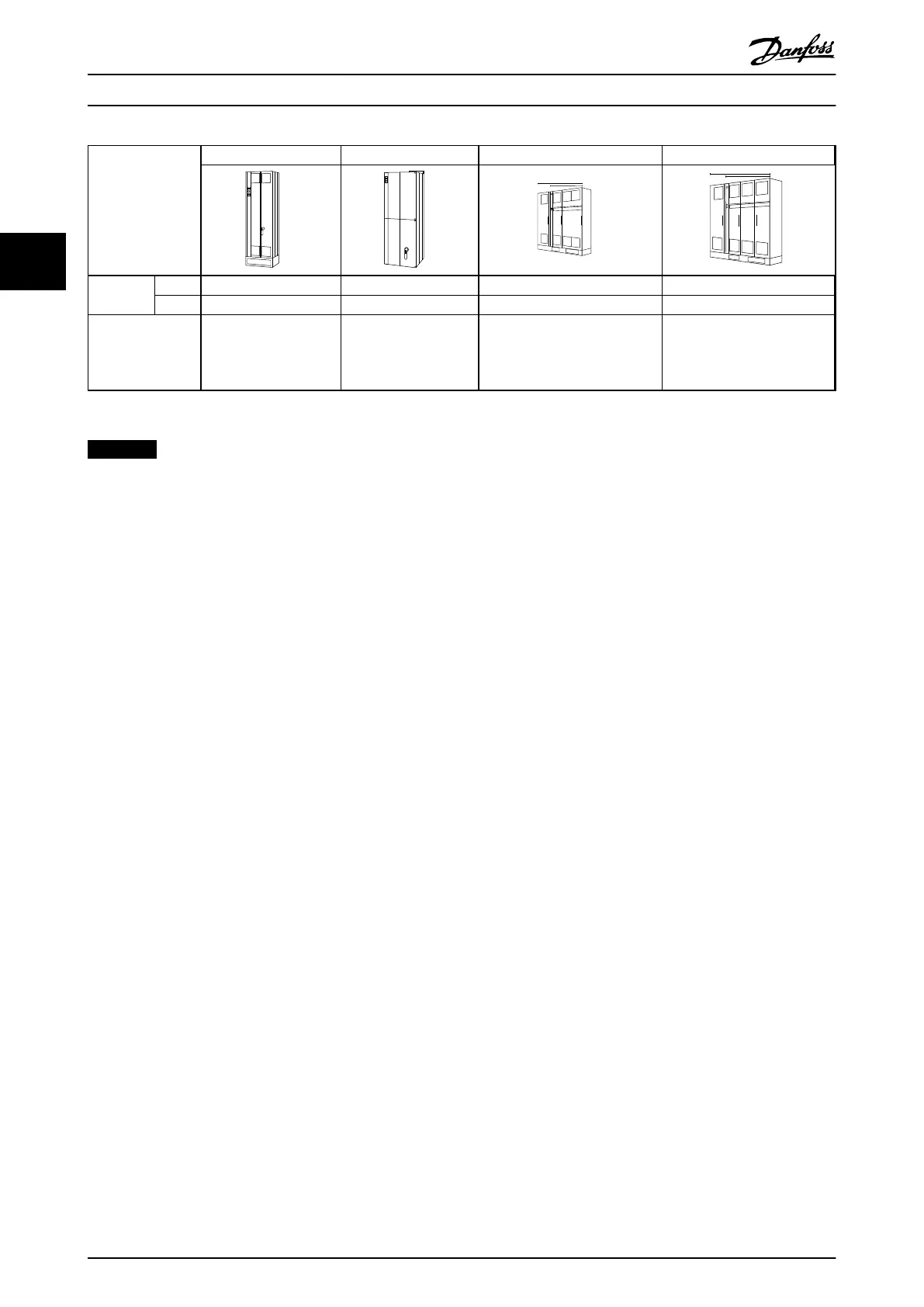

Enclosure type E1 E2 F1/F3 F2/F4

Enclosure

protection

IP 21/54 00 21/54 21/54

NEMA Type 1/Type 12 Chassis Type 1/Type 12 Type 1/Type 12

Normal overload

rated power -

110% overload

torque

315 - 450 kW at 400 V

(380 - 480 V)

450 - 630 kW at 690 V

(525-690 V)

315 - 450 kW at 400 V

(380 - 480 V)

450 - 630 kW at 690 V

(525-690 V)

500 - 710 kW at 400 V

(380 - 480 V)

710 - 900 kW at 690 V

(525-690 V)

800 - 1000 kW at 400 V

(380 - 480 V)

1000 - 1400 kW at 690 V

(525-690 V)

Table 3.6

NOTICE

The F enclosures are available in 4 different sizes, F1, F2, F3 and F4 The F1 and F2 consist of an inverter cabinet on the

right and rectifier cabinet on the left. The F3 and F4 have an additional options cabinet left of the rectifier cabinet. The

F3 is an F1 with an additional options cabinet. The F4 is an F2 with an additional options cabinet.

3.3 Mechanical Installation

Preparation of the mechanical installation of the frequency

converter must be done carefully to ensure a proper result

and to avoid additional work during installation. Start

taking a close look at the mechanical drawings at the end

of this instruction to become familiar with the space

demands.

3.3.1 Tools Needed

To perform the mechanical installation the following

tools are needed:

•

Drill with 10 or 12 mm drill

•

Tape measure

•

Wrench with relevant metric sockets (7-17mm)

•

Extensions to wrench

•

Sheet metal punch for conduits or cable glands

in IP21/Nema 1 and IP54 units

•

Lifting bar to lift the unit (rod or tube max. Ø 5

mm (1 inch), able to lift minimum 400 kg (880

lbs).

•

Crane or other lifting aid to place the frequency

converter in position

•

A Torx T50 tool is needed to install the E1 in IP21

and IP54 enclosure types.

Mechanical Installation VLT HVAC Drive FC 102 Operating Instructions

20 MG11F402 - Rev. 2013-12-16

33

Loading...

Loading...