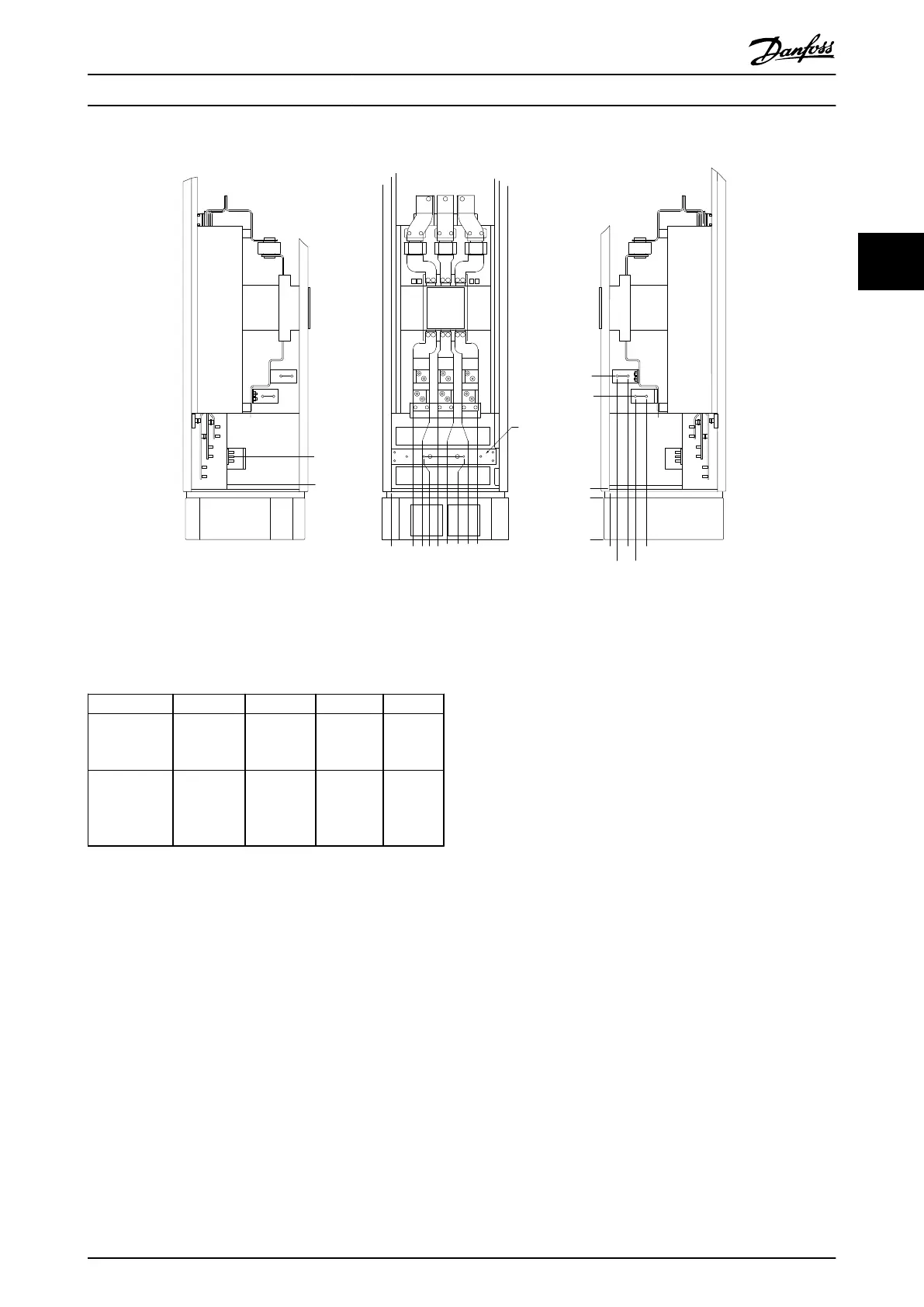

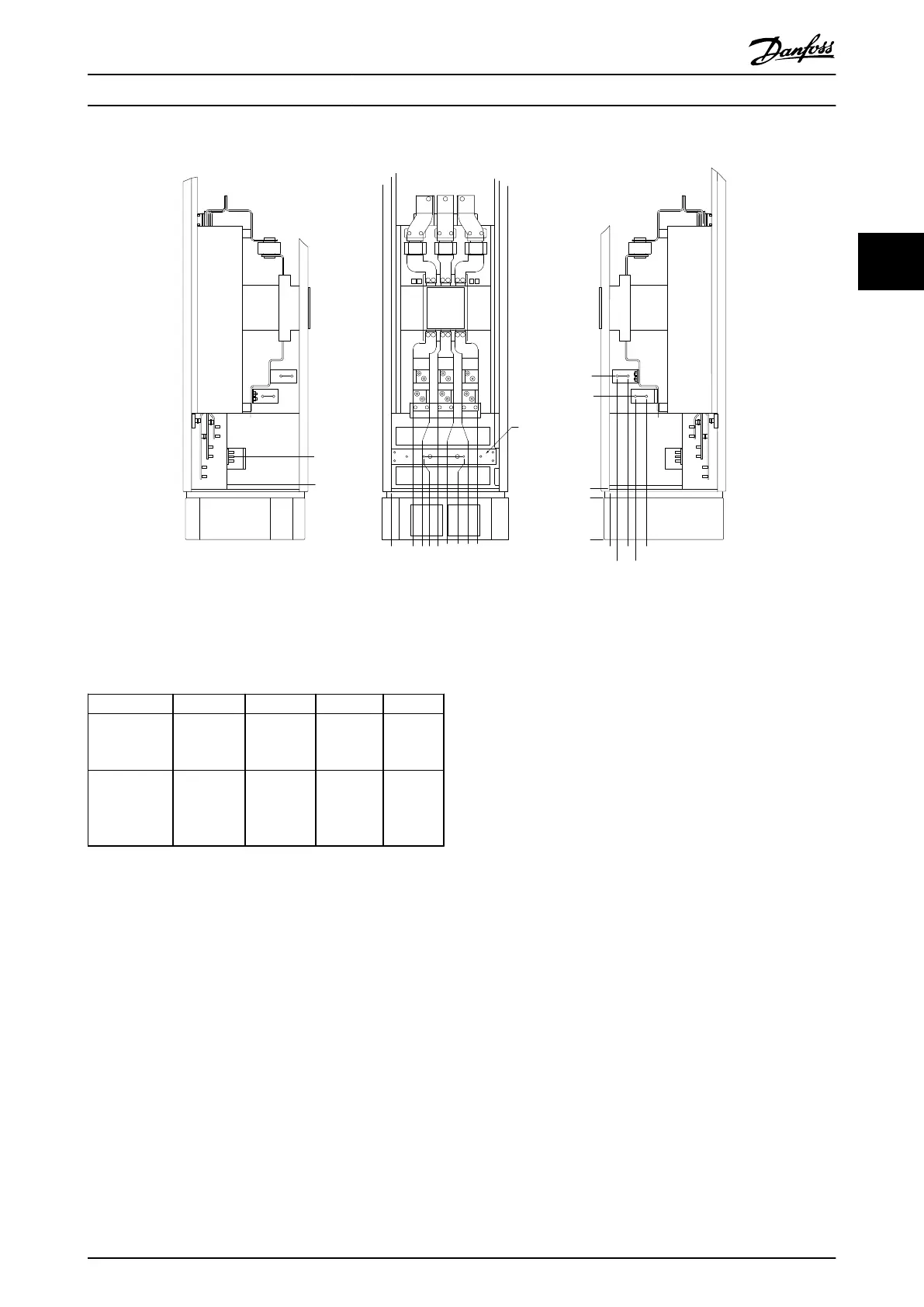

Terminal locations - Options Cabinet with circuit breaker/ molded case switch (F3 and F4)

0.0 [0.00]

134.6 [5.30]

104.3 [4.11]

0.0 [0.00]

179.3 [7.06]

219.6 [8.65]

294.6 [11.60]

334.8 [13.18]

409.8 [16.14]

436.9 [17.20]

0.0 [0.00]

532.9 [20.98]

0.0 [0.00]

44.4 [1.75]

244.4 [9.62]

154.0 [6.06]

344.0 [13.54]

1

2

3

4

5

130BA852.11

Illustration 3.35 Terminal Locations - Options Cabinet with Circuit Breaker/Molded Case Switch (Left Side, Front and Right Side View).

The Gland Plate is 42 mm below .0 Level.

1) Earth Ground Bar

Power size 2 3 4 5

500 kW (480

V), 710-800

kW (690 V)

34.9 86.9 122.2 174.2

560-1000 kW

(480 V),

900-1400 kW

(690 V)

46.3 98.3 119.0 171.0

Table 3.10 Dimensions for Terminal

3.3.6 Cooling and Airflow

Cooling

Cooling can be obtained in different ways, by using the

cooling ducts in the bottom and the top of the unit, by

taking air in and out the back of the unit or by combining

the cooling possibilities.

Duct cooling

A dedicated option has been developed to optimize instal-

lation of IP00/chassis frequency converters in Rittal TS8

enclosures utilizing the fan of the frequency converter for

forced air cooling of the backchannel. The air out of the

top of the enclosure could but ducted outside a facility so

the heat loses from the backchannel are not dissipated

within the control room reducing air-conditioning

requirements of the facility.

See

chapter 3.4.1 Installation of Duct Cooling Kit in Rittal

Enclosures, for further information.

Back cooling

The backchannel air can also be ventilated in and out the

back of a Rittal TS8 enclosure. This offers a solution where

the backchannel could take air from outside the facility

and return the heat loses outside the facility thus reducing

air-conditioning requirements.

Mechanical Installation VLT HVAC Drive FC 102 Operating Instructions

MG11F402 - Rev. 2013-12-16 33

3 3

Loading...

Loading...