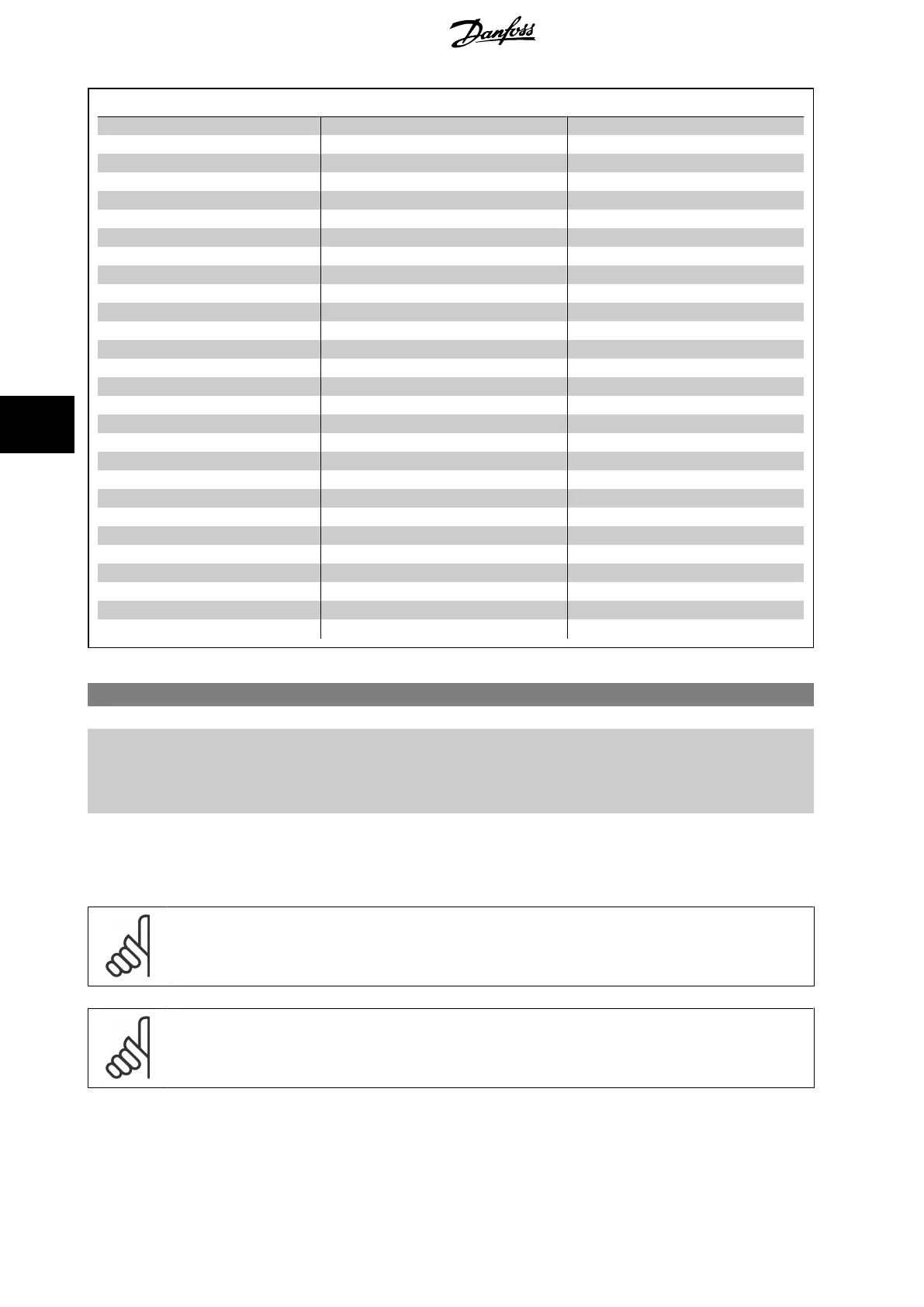

Q3-4 Application Settings

Q3-40 Fan Functions Q3-41 Pump Functions Q3-42 Compressor Functions

Par. 22-60

Broken Belt Function

Par. 22-20

Low Power Auto Set-up

Par. 1-03

Torque Characteristics

Par. 22-61

Broken Belt Torque

Par. 22-21

Low Power Detection

Par. 1-71

Start Delay

Par. 22-62

Broken Belt Delay

Par. 22-22

Low Speed Detection

Par. 22-75

Short Cycle Protection

Par. 4-64

Semi-Auto Bypass Set-up

Par. 22-23

No-Flow Function

Par. 22-76

Interval between Starts

Par. 1-03

Torque Characteristics

Par. 22-24

No-Flow Delay

Par. 22-77

Minimum Run Time

Par. 22-22

Low Speed Detection

Par. 22-40

Minimum Run Time

Par. 5-01

Terminal 27 Mode

Par. 22-23

No-Flow Function

Par. 22-41

Minimum Sleep Time

Par. 5-02

Terminal 29 Mode

Par. 22-24

No-Flow Delay

Par. 22-42

Wake-up Speed [RPM]

Par. 5-12

Terminal 27 Digital Input

Par. 22-40

Minimum Run Time

Par. 22-43

Wake-up Speed [Hz]

Par. 5-13

Terminal 29 Digital Input

Par. 22-41

Minimum Sleep Time

Par. 22-44

Wake-up Ref./FB Difference

Par. 5-40

Function Relay

Par. 22-42

Wake-up Speed [RPM]

Par. 22-45

Setpoint Boost

Par. 1-73

Flying Start

Par. 22-43

Wake-up Speed [Hz]

Par. 22-46

Maximum Boost Time

Par. 1-86

Trip Speed Low [RPM]

Par. 22-44

Wake-up Ref./FB Difference

Par. 22-26

Dry Pump Function

Par. 1-87

Trip Speed Low [Hz]

Par. 22-45

Setpoint Boost

Par. 22-27

Dry Pump Delay

Par. 22-46

Maximum Boost Time

Par. 22-80

Flow Compensation

Par. 2-10

Brake Function

Par. 22-81

Square-linear Curve Approximation

Par. 2-16

AC brake Max. Current

Par. 22-82

Work Point Calculation

Par. 2-17

Over-voltage Control

Par. 22-83

Speed at No-Flow [RPM]

Par. 1-73

Flying Start

Par. 22-84

Speed at No-Flow [Hz]

Par. 1-71

Start Delay

Par. 22-85

Speed at Design Point [RPM]

Par. 1-80

Function at Stop

Par. 22-86

Speed at Design Point [Hz]

Par. 2-00

DC Hold/Preheat Current

Par. 22-87

Pressure at No-Flow Speed

Par. 4-10

Motor Speed Direction

Par. 22-88

Pressure at Rated Speed

Par. 22-89

Flow at Design Point

Par. 22-90

Flow at Rated Speed

Par. 1-03

Torque Characteristics

Par. 1-73

Flying Start

See also

VLT HVAC Drive Programming Guide

for a detailed description of the Function Setups parameter groups.

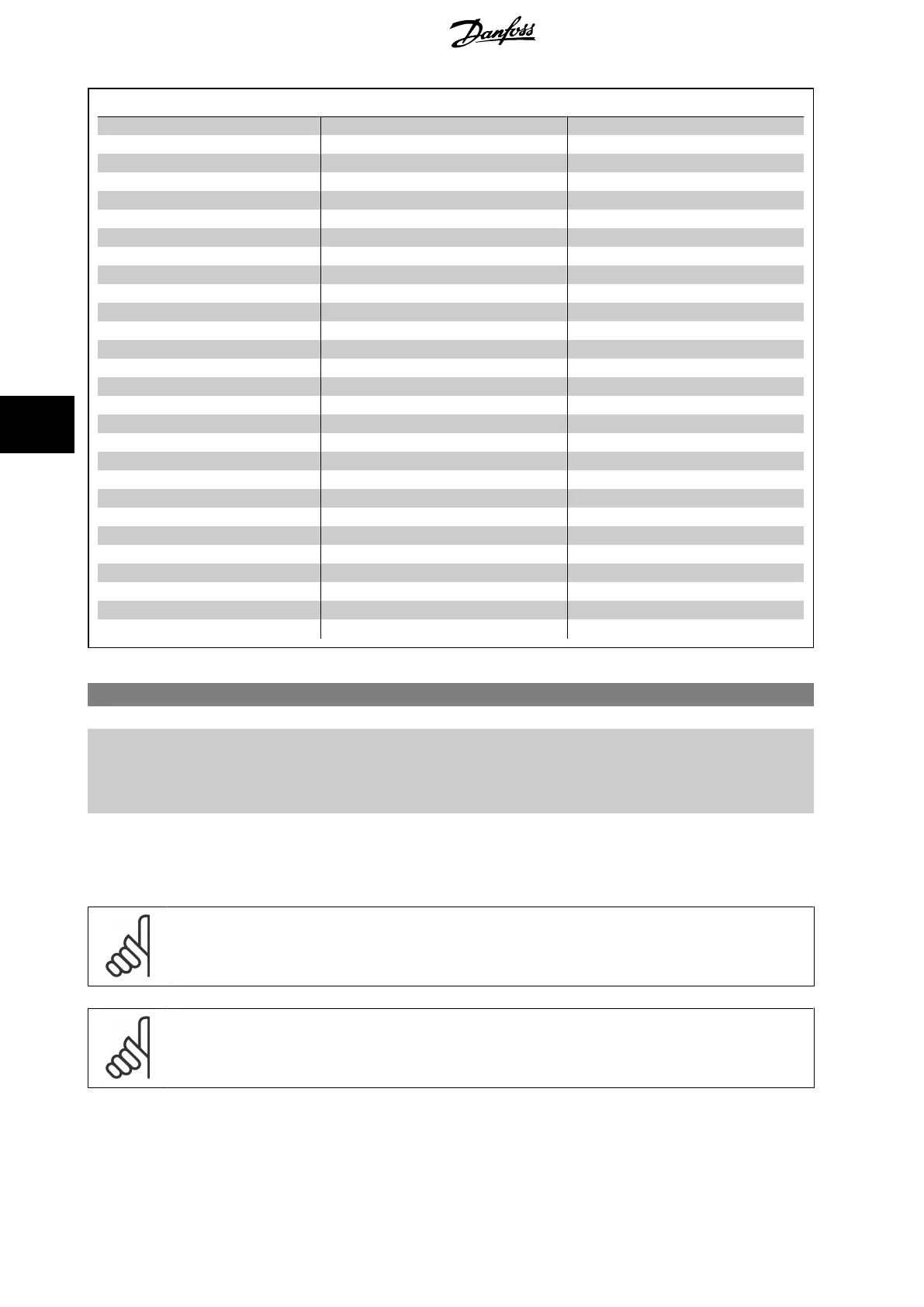

1-00 Configuration Mode

Option: Function:

[0] * Open Loop Motor speed is determined by applying a speed reference or by setting desired speed when in Hand

Mode.

Open Loop is also used if the frequency converter is part of a closed loop control system based on

an external PID controller providing a speed reference signal as output.

[3] Closed Loop Motor Speed will be determined by a reference from the built-in PID controller varying the motor

speed as part of a closed loop control process (e.g. constant pressure or flow). The PID controller

must be configured in par. 20-** or via the Function Setups accessed by pressing the [Quick Menus]

button.

NB!

This parameter cannot be changed when motor is running.

NB!

When set for Closed Loop, the commands Reversing and Start Reversing will not reverse the direction of the motor.

6 How to Programme the Low Harmonic Drive

VLT HVAC Low Harmonic Drive Operating In-

structions

94 MG.16.A1.02 - VLT

®

is a registered Danfoss trademark

6

Loading...

Loading...