4.6 Parameter Group 5: Digital In/Out

4.6.1 5-** Digital In/Out

The following describes all digital input command

functions and signals.

4.6.2 5-1* Digital Inputs

Parameters for configuring the functions for the input

terminals.

The digital inputs are used for selecting various functions

in the frequency converter. All digital inputs can be set to

the following:

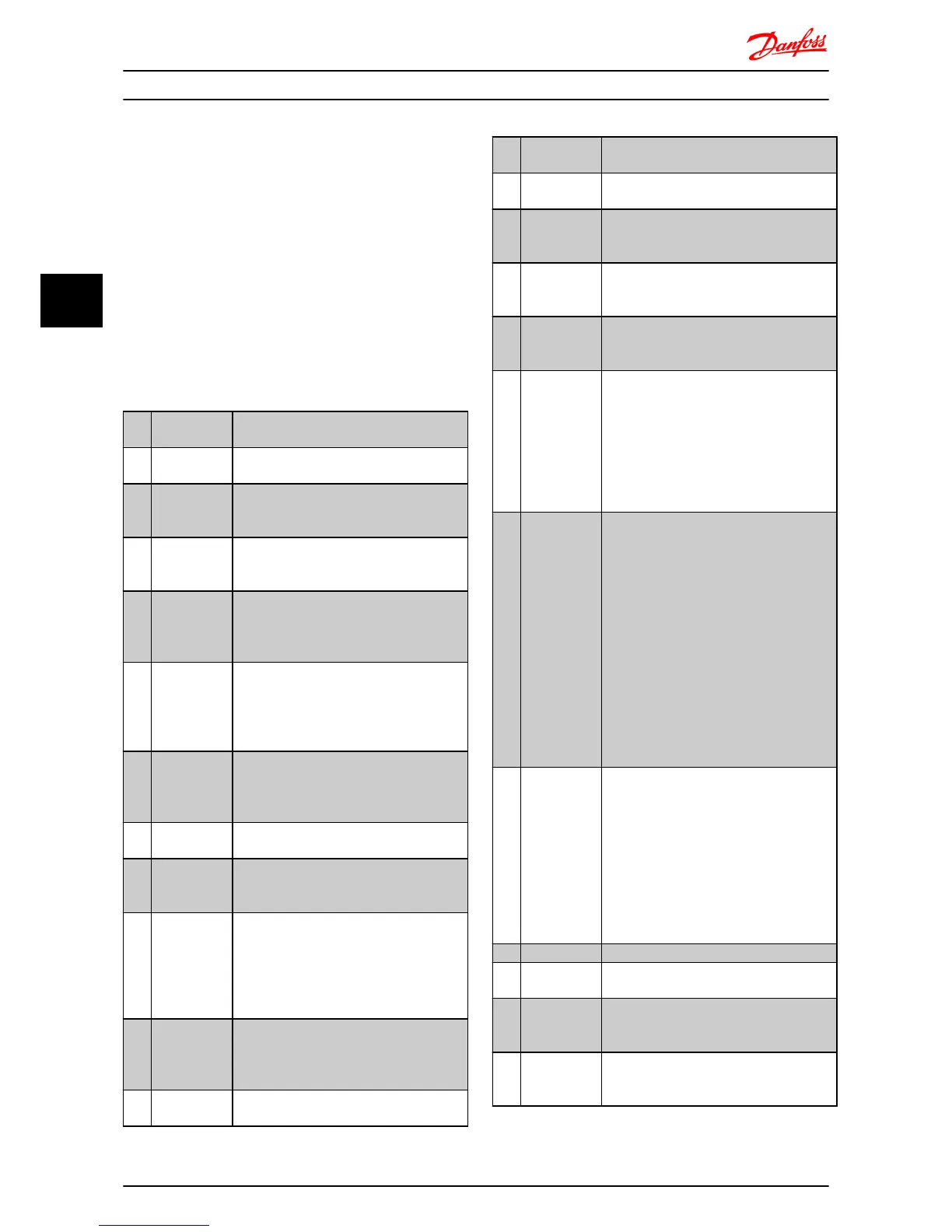

[0] No Operation The frequency converter will not react to

signals transmitted to the terminal.

[1] Reset Reset the frequency converter after a Trip/

Alarm. Not all alarms can be reset.

[2 ] Coast Inverse Coasting stop, inverted input (NC). The

frequency converter leaves the motor in free

mode.

[3] Coast and

reset inv.

Reset and coasting stop inverted input (NC).

The frequency converter resets and leaves

the motor in free mode.

[4] Quick stop

inverse

Inverted input (NC). Generates a stop in

accordance with the quick-stop ramp time

set in 3-81 Quick Stop Ramp Time. When

motor stops, shaft is in free mode.

[5] DC-brake inv. Inverted input for DC braking (NC). Stops

motor by energizing it with DC current for a

certain time period, see 2-01 DC Brake

Current. Function is only active when value

in 2-02 DC-Braking Time is different from 0.

[6] Stop inv. Stop inverted function. Generates stop

function when selected terminal goes from

logical level “1” to “0”. Stop is performed

according to selected ramp time.

[8] Start Select start for a start/stop command.

1 = Start, 0 = stop.

[9] Latched start Motor starts if a pulse is applied for min. 2

ms. Motor stops when Stop inverse is

activated.

[10] Reversing Change direction of motor shaft rotation.

Reversing signal only changes direction of

rotation; it does not activate start function.

Select [2] Both directions in 4.10 Motor Speed

Direction.

0 = normal, 1 = reversing.

[11] Start

reversing

Use for start/stop and for reversing at the

same time. Signals on start [8] are not

allowed at the same time.

0 = stop, 1 = start reversing.

[12] Enable start

forward

Use if motor shaft must rotate clockwise at

start.

[13] Enable start

reverse

Use if motor shaft must rotate counter-

clockwise at start.

[14] Jog

Use for activating jog speed. See 3-11 Jog

Speed.

[16] Preset

reference bit

0

Preset reference bit 0, 1 and 2 enables a

choice between one of the eight preset

references according to below.

[17] Preset

reference bit

1

Same as preset reference bit 0 [16], see 3-10

Preset Reference.

[18] Preset

reference bit

2

Same as preset reference bit 0 [16].

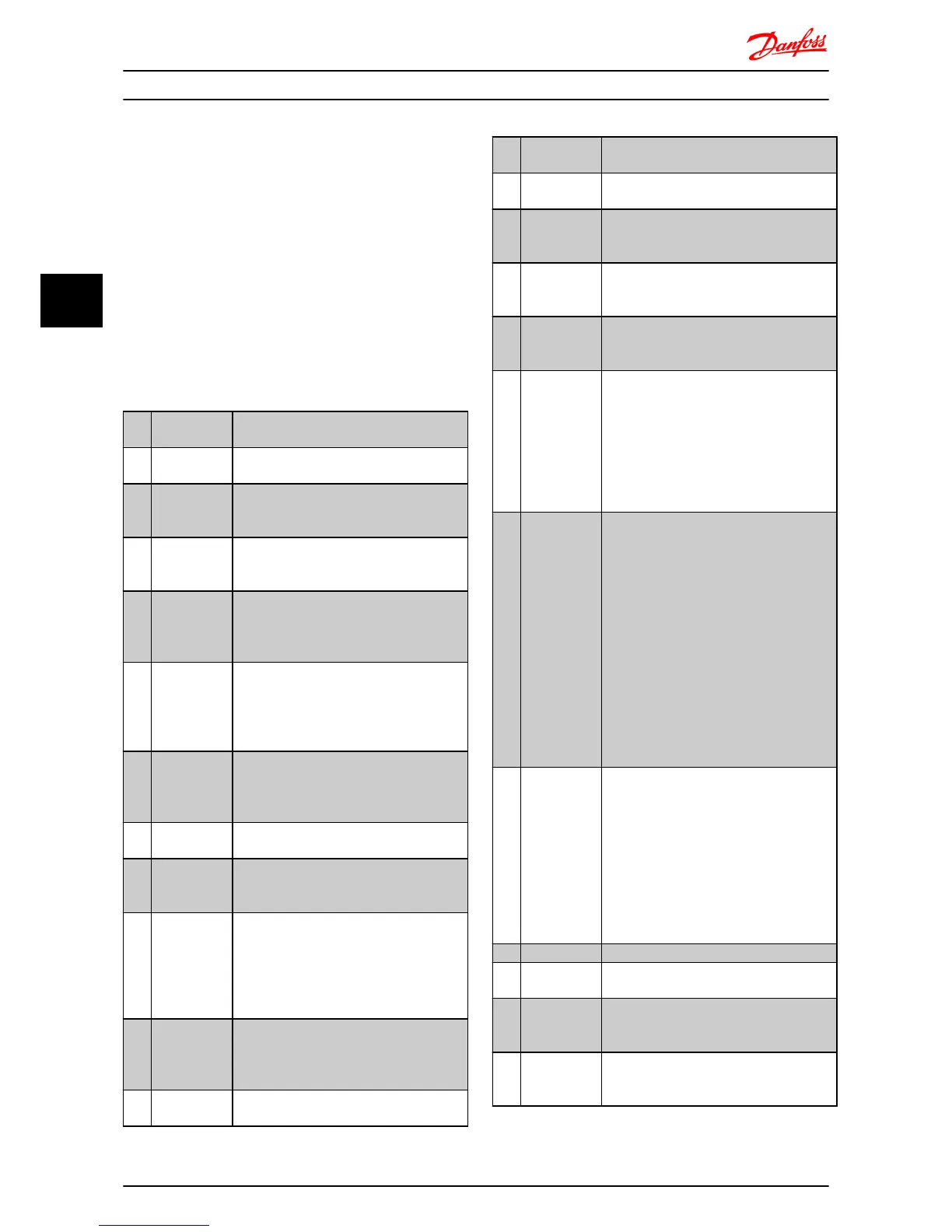

[19] Freeze

reference

Freeze actual reference. The frozen reference

is now the point of enable/condition for

Speed up and Speed down to be used. If

Speed up/down is used, speed change

always follows ramp 2 (3-51 Ramp2 Ramp-up

Time and 3-52 Ramp2 Ramp-down Time) in

the range 3-02 Minimum Reference - 3-03

Maximum Reference.

[20] Freeze output Freeze the actual motor frequency (Hz). The

frozen motor frequency is now the point of

enable/condition for Speed up and Speed

down to be used. If Speed up/down is used,

the speed change always follows ramp 2 in

the range 4-12 Motor Speed Low Limit - 4-14

Motor Speed High Limit.

NOTE

When freeze output is active, the

frequency converter cannot be stopped

via a low [8] Start signal. Stop the

frequency converter via a terminal

programmed for Coasting Inverse [2] or

Coast and reset, inverse [3].

[21] Speed up Select Speed up and Speed down if digital

control of the up/down speed is desired

(motor potentiometer). Activate this function

by selecting either Freeze reference or

Freeze output. When Speed-up is activated

for less than 400 ms. the resulting reference

will be increased by 0.1%. If Speed-up is

activated for more than 400 ms. the

resulting reference will ramp according to

ramp 2 in 3-51 Ramp2 Ramp-up Time.

[22] Speed down Same as Speed-up [21].

[23] Setup select

bit 0

Set 0-10 Active set-up to Multi set-up.

Logic 0 = set up 1, Logic 1 = Set up 2.

[26] Precise stop

inverse (only

terminal 33)

Prolong the stop signal to give a precise

stop independent of scan time. The function

is available for terminal 33 only.

[27] Start, precise

stop (only

terminal 33)

As [26], but including Start.

Parameter Descriptions

VLT

®

Micro Drive FC 51 Programming Guide

28 MG02C602 - VLT

®

is a registered Danfoss trademark

44

Loading...

Loading...