4.8 Parameter Group 7: Controllers

4.8.1 7-** Controllers

Parameters group for configuring application controls.

4.8.2 7-2* Process Ctrl. Feedback

Select feedback sources and handling for Process PI

Control.

NOTE

Set 3-15 Reference 1 Source to [0] No Function in order to

use Analog Input as a feedback signal.

In order to use analog input as a feedback resource, do

not use the same resource as reference resource in 3-15,

3-16 and 3-17.

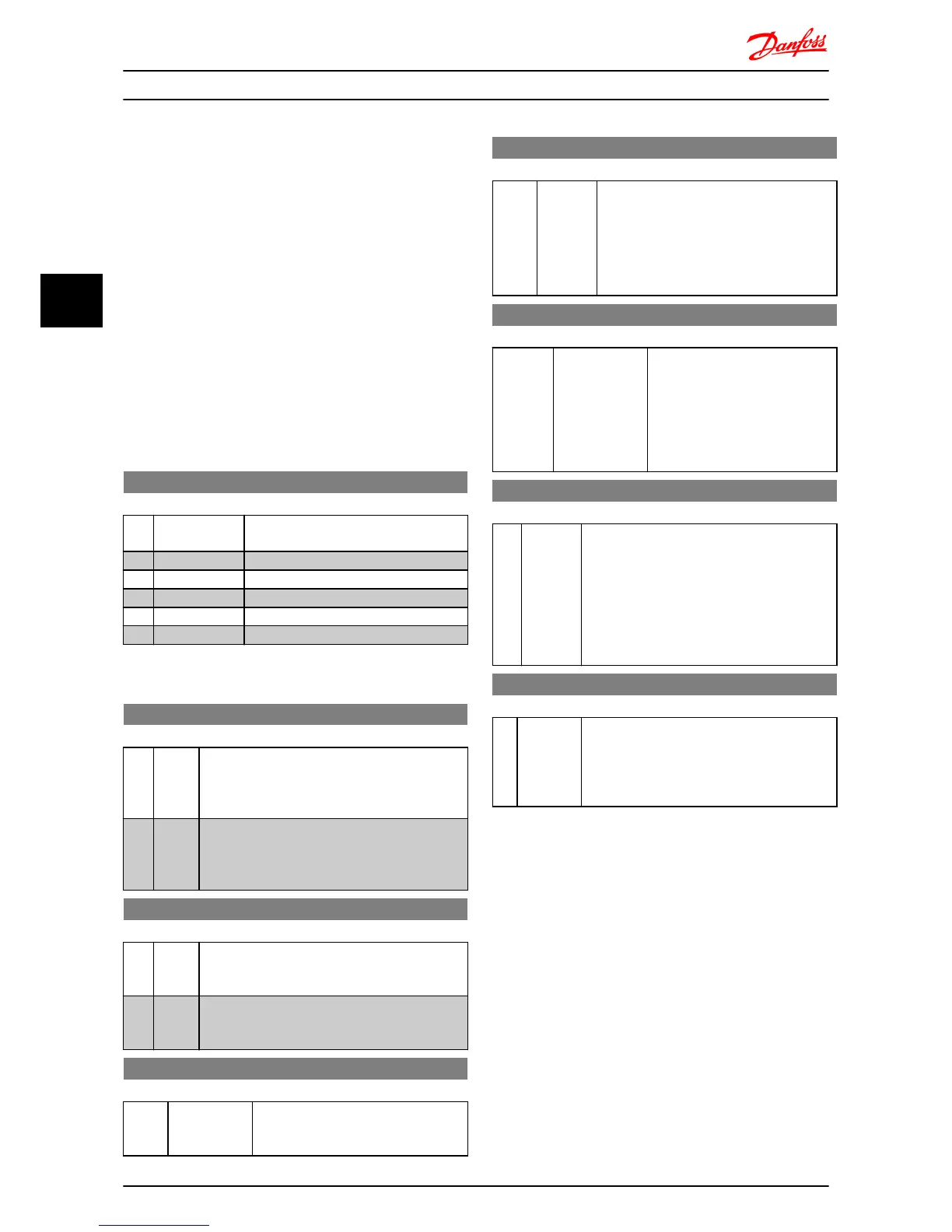

7-20 Process CL Feedback Resources

Option: Function:

Select input to function as feedback

signal.

[0] * No Function

[1] Analog Input 53

[2] Analog Input 60

[8] Pulse Input 33

[11] Local Bus Ref.

4.8.3 7-3* Process PI Control

7-30 Process PI Normal/Inverse Control

Option: Function:

[0] * Normal Feedback larger than setpoint result in a speed

reduction.

Feedback less than setpoint result in a speed

increase.

[1] Inverse Feedback larger than setpoint result in a speed

increase.

Feedback less than setpoint result in a speed

reduction.

7-31 Process PI Anti Windup

Option: Function:

[0] Disable Regulation of a given error will continue even

when the output frequency cannot be increased/

decreased.

[1] * Enable PI-controller ceases from regulating a given error

when the output frequency cannot be increased/

decreased.

7-32 Process PI Start Speed

Range: Function:

0.0 Hz* [0.0-200.0 Hz] Until the set motor speed has been

reached the frequency converter

operates in Open Loop mode.

7-33 Process PI Proportional Gain

Option: Function:

[0.01] * 0.00-10.00 Enter the value for the P proportional gain,

i.e. the multiplication factor of the error

between the set point and the feedback

signal.

NOTE

0.00 = Off.

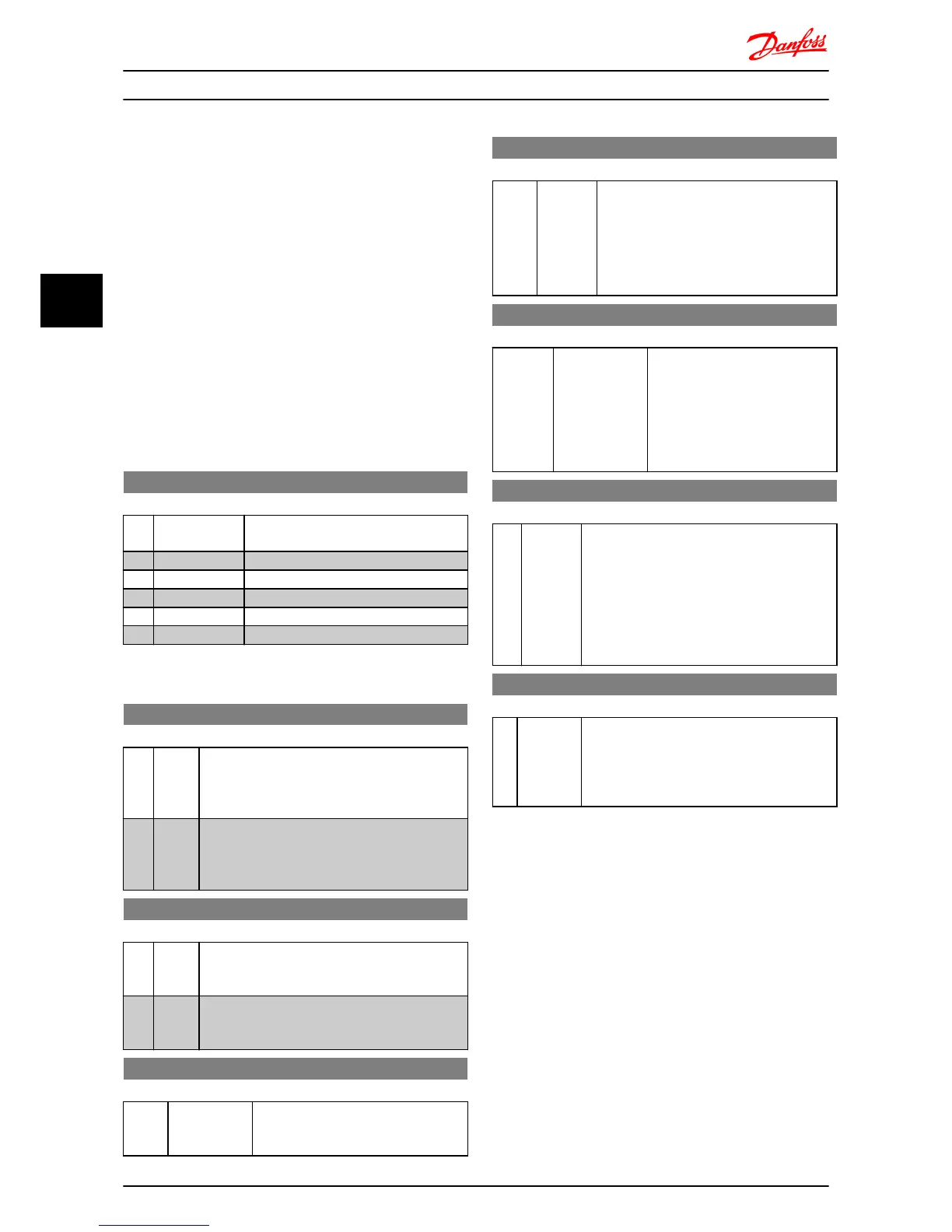

7-34 Process PI Integral Time

Range: Function:

9999.00 s* [0.10-9999.00 s] The integrator provides an

increasing gain at a constant error

between the set point and the

feedback signal. The integral time

is the time needed by the

integrator to reach the same gain

as the proportional gain.

7-38 Process Feed Forward Factor

Range: Function:

0%* [0-400%] The FF factor sends a part of the reference

signal around the PI controller which then only

affects part of the control signal.

By activating the FF factor less overshoot and

high dynamics are gained when changing the

setpoint.

This parameter is always active when 1-00

Configuration Mode is set to [3] Process.

7-39 On Reference Bandwidth

Range: Function:

5% [0-200% ] Enter the value for the On Reference Bandwidth.

The PI control error is the difference between

setpoint and feedback and when this is less

than the value set in this parameter the On

Reference is active.

Parameter Descriptions

VLT

®

Micro Drive FC 51 Programming Guide

36 MG02C602 - VLT

®

is a registered Danfoss trademark

44

Loading...

Loading...