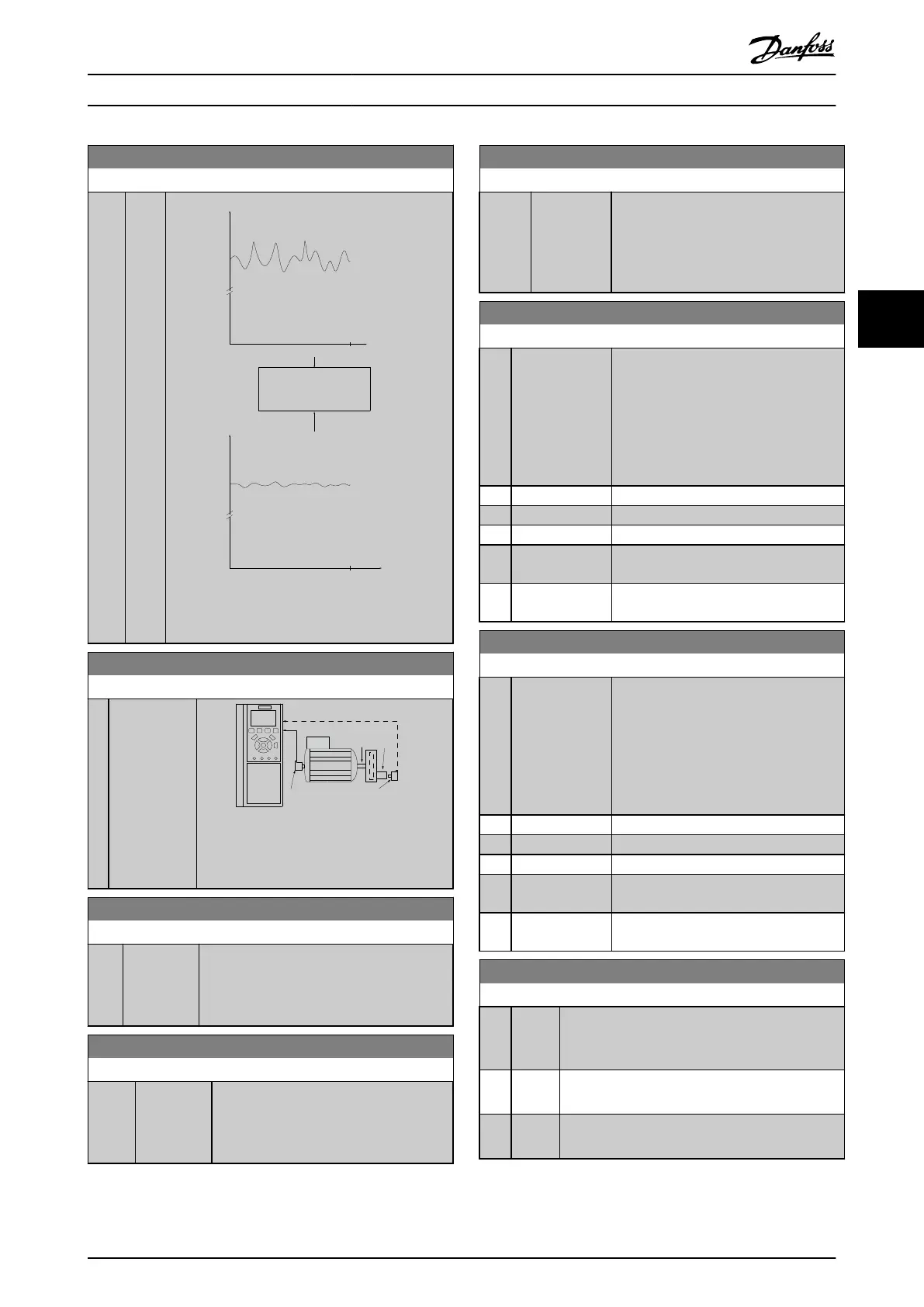

7-06 Speed PID Lowpass Filter Time

Range: Function:

0.6

0.6

f

g

= 10 Hz

175ZA293.11

Feedback

Disturbed feedback signal

t (Sec.)

t (Sec.)

Filtered feedback signal

Lowpass lter

Feedback

Illustration 4.15 Feedback Signal

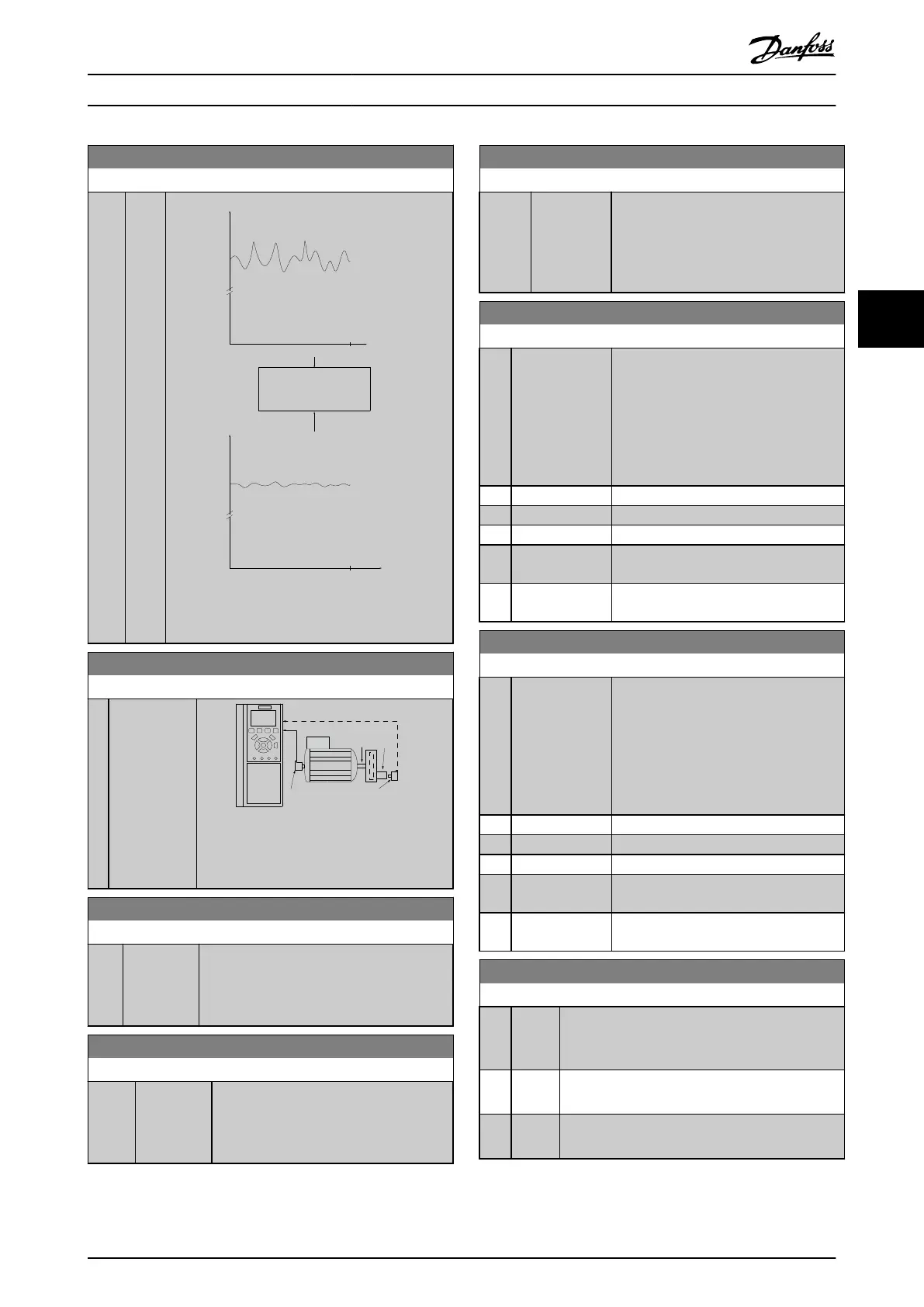

7-07 Speed PID Feedback Gear Ratio

Range: Function:

1* [0.0001 - 32 ]

Par 7-07=1.00 Par 7-07=n1/n2

130BA871.10

Motor

n1 n2

Illustration 4.16 Speed PID Feedback Gear

Ratio

7-08 Speed PID Feed Forward Factor

Range: Function:

0 %* [0 - 500 %] The reference signal bypasses the speed

controller by the amount specied. This

feature increases the dynamic performance

of the speed control loop.

7-12 Torque PID Proportional Gain

Range: Function:

100 %* [0 - 500 %] Enter the proportional gain value for the

torque controller. Selection of a high value

makes the controller react faster. Too high

a setting leads to controller instability.

7-13 Torque PID Integration Time

Range: Function:

0.020 s* [0.002 - 2 s] Enter the integration time for the torque

controller. The lower the integration time,

the faster the controller reacts. However,

too low a setting leads to controller

instability.

7-20 Process CL Feedback 1 Resource

Option: Function:

The eective feedback signal is made up

of the sum of up to 2 dierent input

signals. Select which input is treated as

the source of the rst of these signals.

The 2nd input signal is dened in

parameter 7-22 Process CL Feedback 2

Resource.

[0] * No function

[1] Analog Input 53

[2] Analog Input 54

[3] Frequency input

29

[4] Frequency input

33

7-22 Process CL Feedback 2 Resource

Option: Function:

The eective feedback signal is made up

of the sum of up to 2 dierent input

signals. Select which input is treated as

the source of the 2nd of these signals.

The rst input signal is dened in

parameter 7-20 Process CL Feedback 1

Resource.

[0] * No function

[1] Analog Input 53

[2] Analog Input 54

[3] Frequency input

29

[4] Frequency input

33

7-30 Process PID Normal/ Inverse Control

Option: Function:

Normal and inverse controls are implemented by

introducing a dierence between the reference

signal and the feedback signal.

[0] * Normal Sets process control to increase the output

frequency.

[1] Inverse Sets process control to decrease the output

frequency.

Parameter Descriptions Programming Guide

MG07C102 Danfoss A/S © 12/2015 All rights reserved. 67

4 4

Loading...

Loading...