DSE Model 8620 Main Control and ATS Operators Manual

115

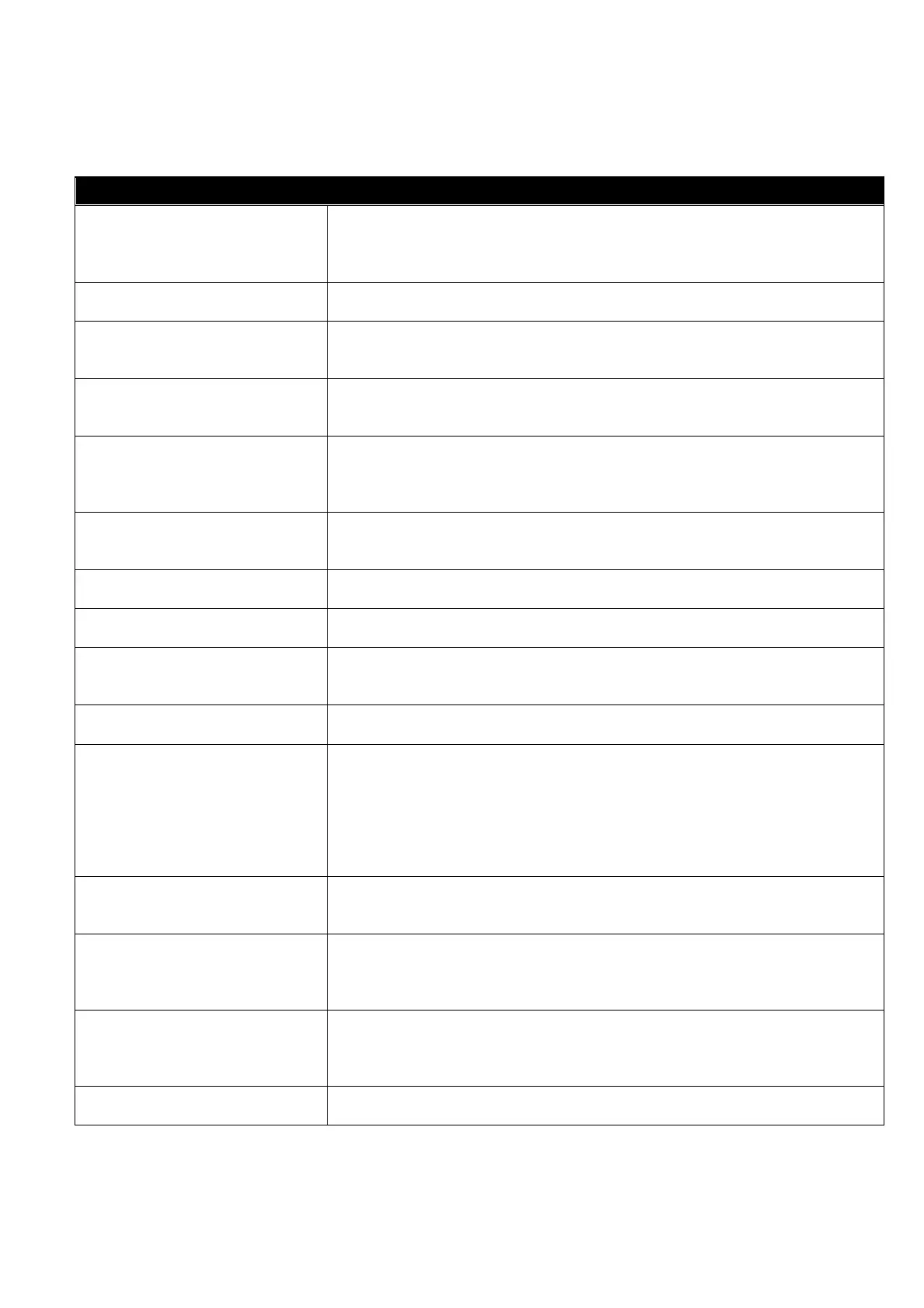

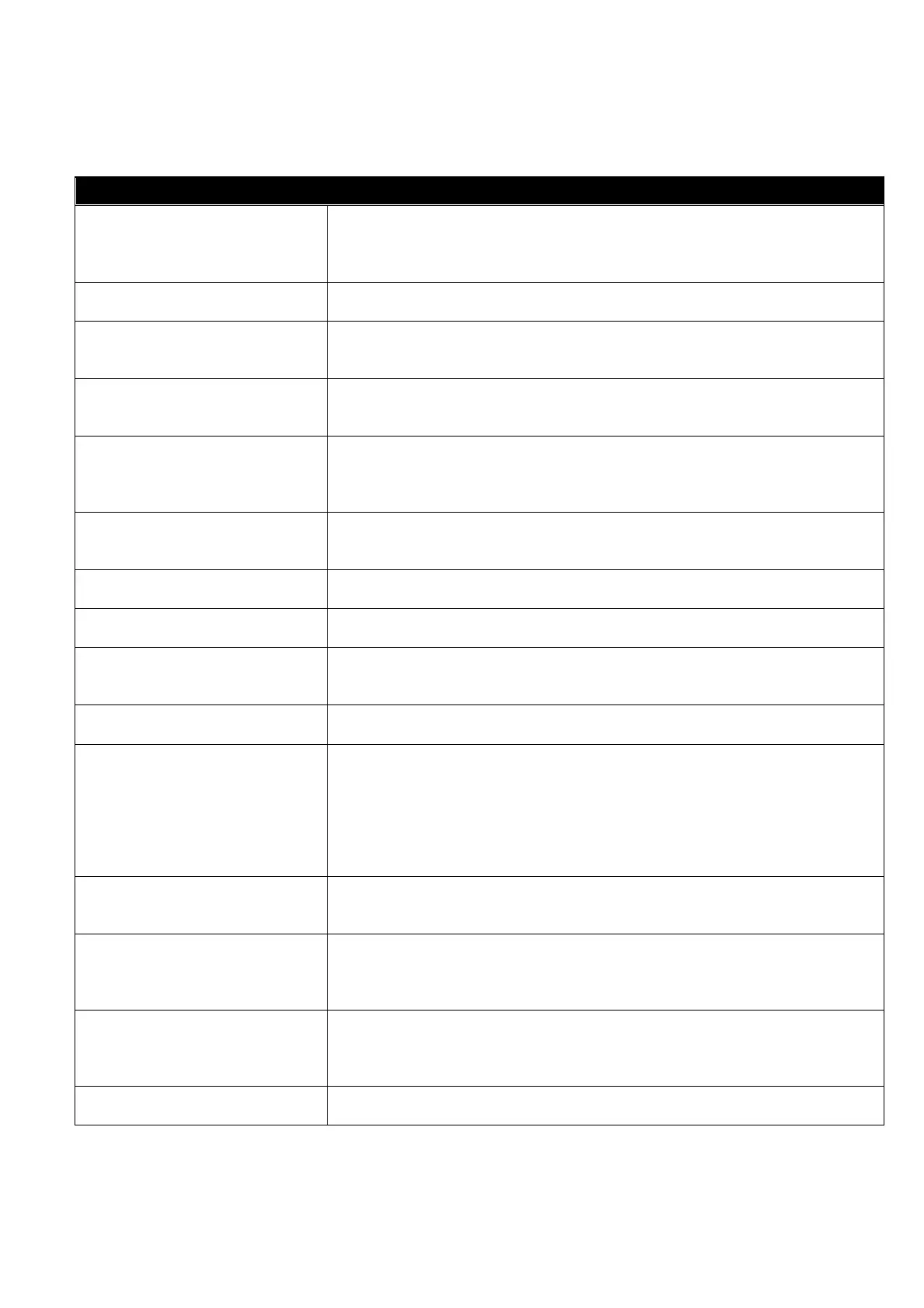

14 FAULT FINDING

SYMPTOM POSSIBLE REMEDY

Unit is inoperative

Read/Write configuration does not

operate

Check the battery and wiring to the unit. Check the DC supply. Check the DC

fuse.

Unit shuts down Check DC supply voltage is not above 35 Volts or below 9 Volts

Check the operating temperature is not above 70°C. Check the DC fuse.

Unit locks out on Emergency Stop If no Emergency Stop Switch is fitted, ensure that a DC positive signal is

connected to the Emergency Stop input. Check emergency stop switch is

functioning correctly. Check Wiring is not open circuit.

Intermittent Magnetic Pick-up

sensor fault

Ensure that Magnetic pick-up screen only connects to earth at one end, if

connected at both ends, this enables the screen to act as an aerial and will pick

up random voltages. Check pickup is correct distance from the flywheel teeth.

Low oil Pressure fault operates

after engine has fired

Check engine oil pressure. Check oil pressure switch/sensor and wiring. Check

configured polarity (if applicable) is correct (i.e. Normally Open or Normally

Closed) or that sensor is compatible with the 73x0 Module and is correctly

configured.

High engine temperature fault

operates after engine has fired.

Check engine temperature. Check switch/sensor and wiring. Check configured

polarity (if applicable) is correct (i.e. Normally Open or Normally Closed) or that

sensor is compatible with the 8600 series module.

Shutdown fault operates Check relevant switch and wiring of fault indicated on LCD display. Check

configuration of input.

Warning fault operates Check relevant switch and wiring of fault indicated on LCD display. Check

configuration of input.

Fail to Start is activated after pre-

set number of attempts to start

Check wiring of fuel solenoid. Check fuel. Check battery supply. Check battery

supply is present on the Fuel output of the module. Check the speed-sensing

signal is present on the 8600 series module’s inputs. Refer to engine manual.

Continuous starting of generator

when in AUTO

Check that there is no signal present on the “Remote Start” input. Check

configured polarity is correct.

Generator fails to start on receipt

of Remote Start signal.

Check Start Delay timer has timed out.

Check signal is on “Remote Start” input. Confirm correct configuration of input

Check that the oil pressure switch or sensor is indicating low oil pressure to the

controller. Depending upon configuration, then set will not start if oil pressure is

not low.

Pre-heat inoperative Check wiring to engine heater plugs. Check battery supply. Check battery

supply is present on the Pre-heat output of module. Check pre-heat

configuration is correct.

Starter motor inoperative Check wiring to starter solenoid. Check battery supply. Check battery supply is

present on the Starter output of module. Ensure that the Emergency Stop input

is at Positive. Ensure oil pressure switch or sensor is indicating the “low oil

pressure” state to the 8610 series controller.

Engine runs but generator will not

take load

Check Warm up timer has timed out. Ensure generator load inhibit signal is not

present on the module inputs. Check connections to the switching device.

Note that the set will not take load in manual mode unless there is an active

remote start on load signal.

Synchronising or load sharing is

not operating satisfactorily

Follow the DSE “4 Steps To Synchronising” as detailed in the following section.

Loading...

Loading...