FUSED GLASS PROJECTS

Working with Tested Compatible Glasses

To ensure success when fusing glass, use glass that has been pre-tested by the

manufacturer

How to prepare your glass project

Select glass that is “tested compatible” and has the same COE (Coefficient of

Expansion) for the entire project.

Glass projects should be comprised of two or more layers of glass from edge to

edge because at a full fuse, glass likes to be approximately ¼” (6mm) thick. The

best designs are constructed using a single piece of glass for the base piece,

with a cut design as the second layer. If you‟d like you can add more detail to

your design with frit, stringers, and confetti. During assembly, take the time to

make sure your glass pieces fit well together. If necessary, use a glass grinder

to aid with the fit. A helpful tip to reducing and eliminating grinder marks from

showing up in your fused pieces is to use an extra fine grit grinder bit.

Oil from your glass cutter, as well as oil from your fingers while handling the

pieces, is left on the surface of the glass. Thoroughly clean your glass pieces

with either a light detergent, like Dawn dishwashing detergent, and water or with

denatured alcohol. If you did any heavy grinding, also use a soft bristled brush,

like an old toothbrush, to scrub the edges and remove any residual ground glass

debris. After the glass had been cleaned and dried well, only handle it by the

edges when assembling your project.

To make transporting your project between your workspace and the kiln easier,

you can use water soluble glue. Use glue very sparingly on the backside of the

glass. Allow the glue to completely dry before you try to move your piece.

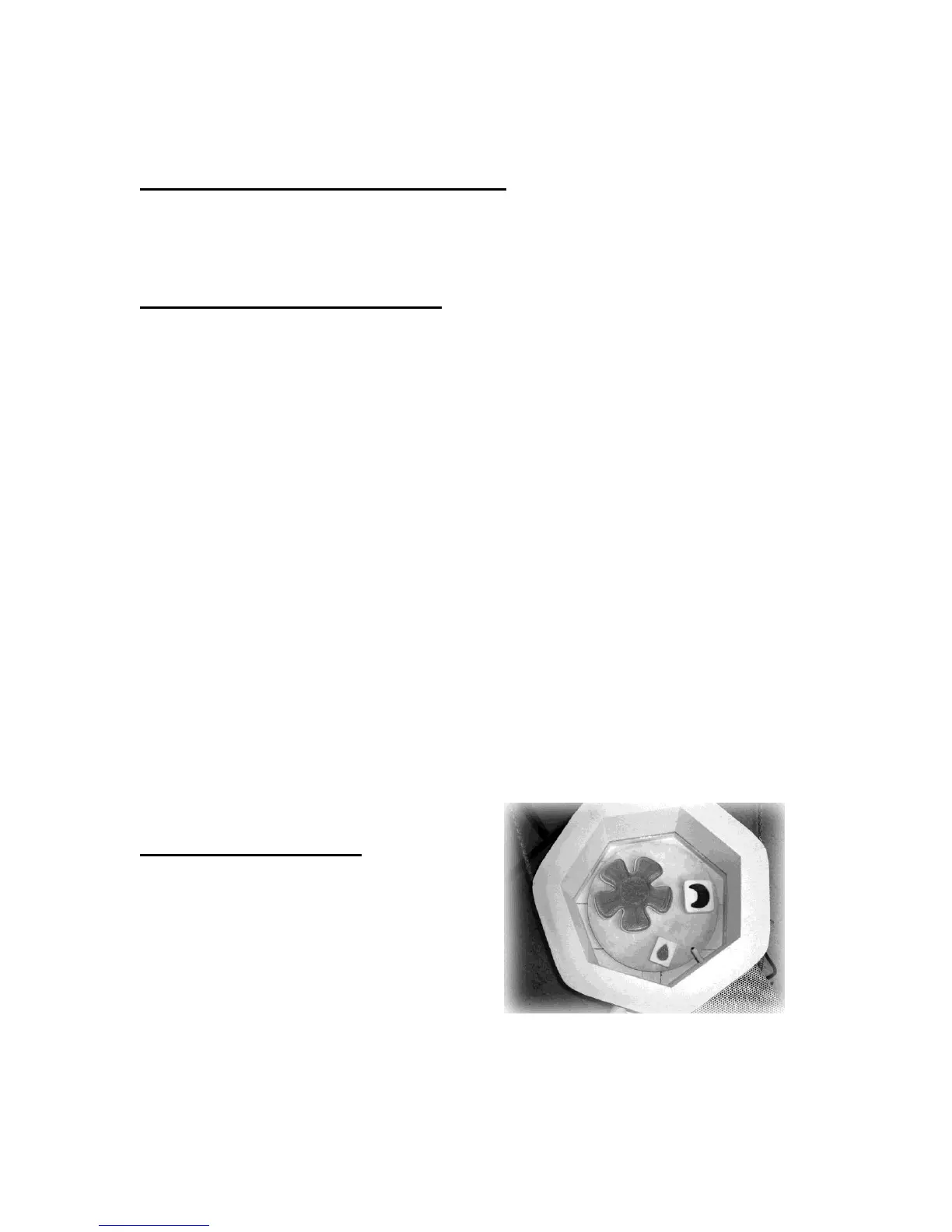

Before setting up your glass projects on the kiln shelf, first place the kiln shelf in

the kiln. If you are planning to fire more than one piece at a time, make sure to

position your glass projects no closer than ¾” to 1” to each other and also no

closer to the edge than ¾”.

Firing your Glass Project

When you first start fusing, the entire process

may seem to be complicated, but it‟s really

simpler than it may have originally sounded.

Fusing is all about controlled heating and

cooling of glasses in a kiln. As glass is being

fired in a kiln it goes through many physical

changes based on the temperature zone that

it‟s in.

Below 1000°F (538°C), glass is very rigid and is very susceptible to thermal

shock, or breaking, if heated or cooled too quickly. Visually, the glass appears to

be very rigid and it will look the same as if it were room temperature. Resist the

temptation to open the kiln and peek inside, because glass is very fragile at this

point and large temperature swings in the kiln will cause the glass to break.

Loading...

Loading...