Revision February, 2017 B-1

Appendix B Maintenance and

Inspection

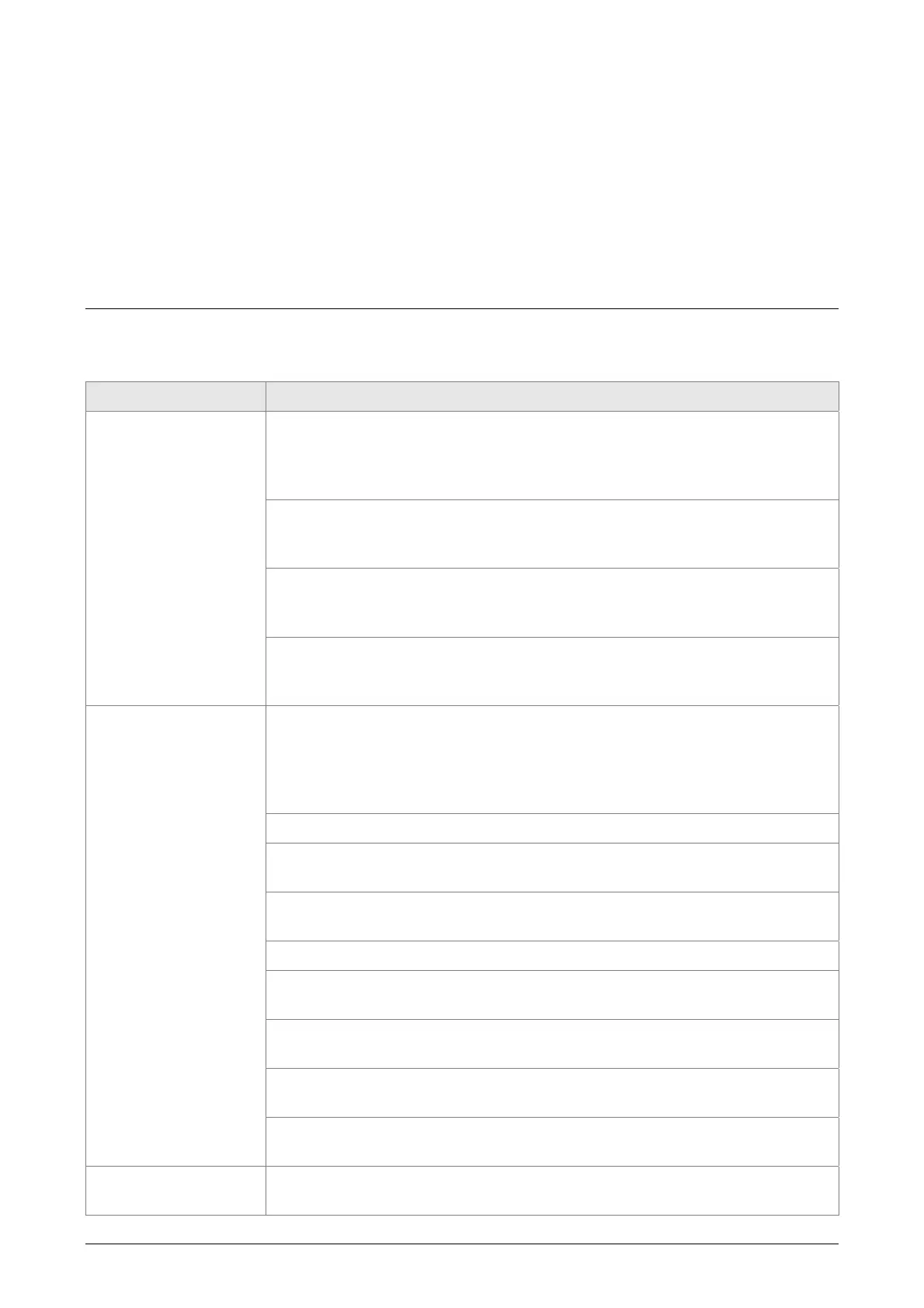

Basic Inspection

Item Content

General inspection

Periodically check if the screws of the servo drive, the connection

between the motor shaft and the mechanical system as well as the

connection of terminal block and mechanical system are securely

tightened.

The gap of the control chamber and the installation of the cooling fan

should free from oil, water or metallic particles. Also, the servo drive

shall free from the cutting power of the power drill.

If the control chamber is installed in the site which contains harmful gas

or full of dust, please be ensured the servo drive is free from the

harmful gas and dust.

When making encoder cable or wire rods, please be ensured the wiring

is correct. Otherwise, the motor may have sudden unintended

acceleration or be burned.

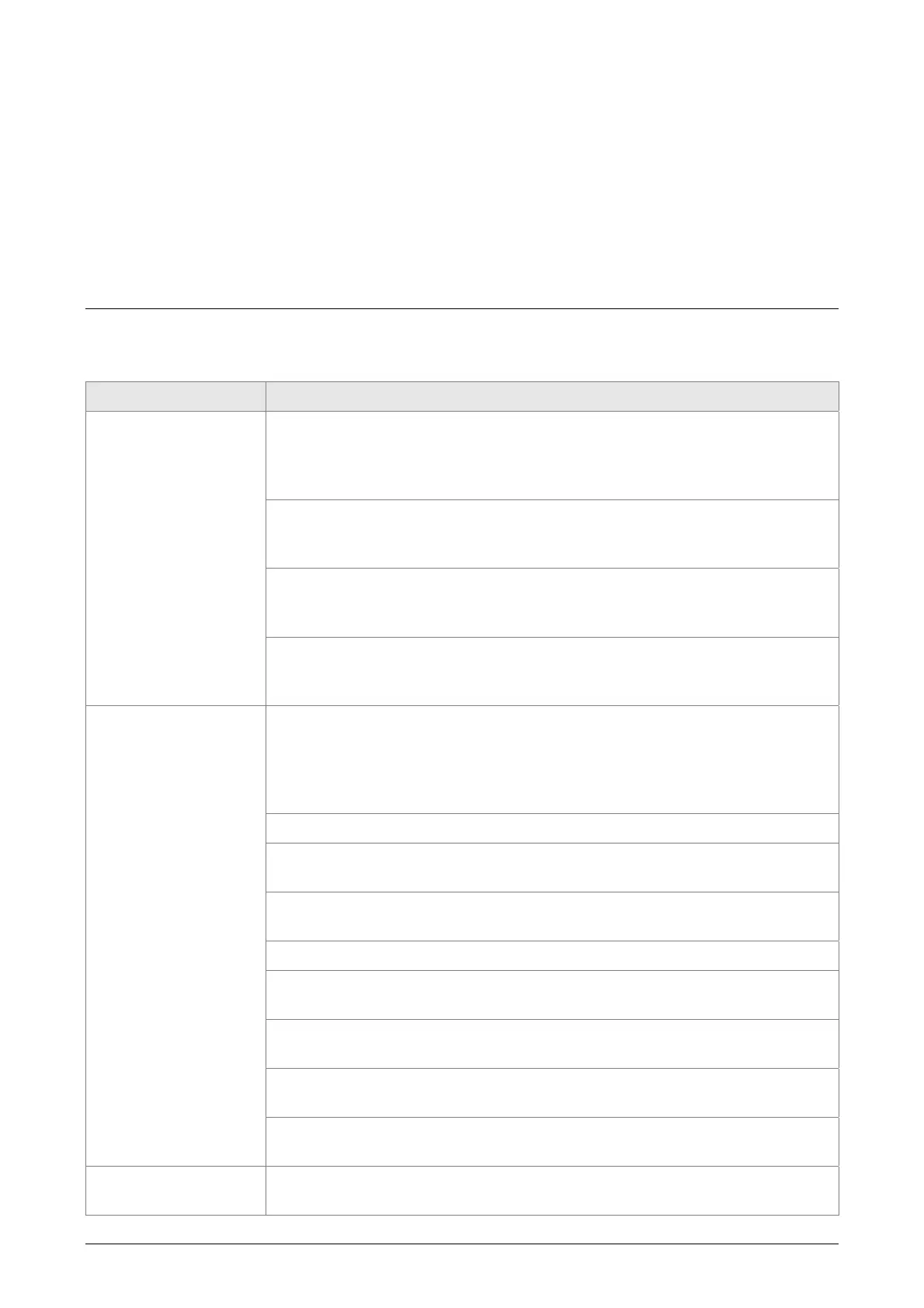

Inspection before

operation

(has not applied to the

power yet)

To avoid the electric shock, the ground terminal of the servo drive

should firmly connect to the ground terminal of the control chamber. If

the wiring is needed, wait at least 10 minutes after disconnecting the

drive from the main supply power, or discharge electricity by discharge

device.

The splicing parts of the wiring terminal should be isolated.

Make sure the wiring is correct so as to avoid the damage or any

abnormity.

Check if the electric conductivity objects including sheetmetal (such as

screws) or inflammable objects are not inside the servo drive.

Check if the control switch is in OFF status.

Do not place the servo drive of external regenerative resistor on

inflammable objects.

To avoid the electromagnetic brake losing efficacy, please check if stop

function and circuit break function can work normally.

If the peripheral devices are interfered by the electronic instruments,

please reduce electromagnetic interference with devices.

Please make sure the external voltage level of the servo drive is

correct.

Inspection before

The encoder cable should avoid excessive stress. When the motor is

running, please be ensured the cable is not frayed or over extended.

Loading...

Loading...