ASDA-A2 Chapter 8 Parameters

Revision February, 2017 8-219

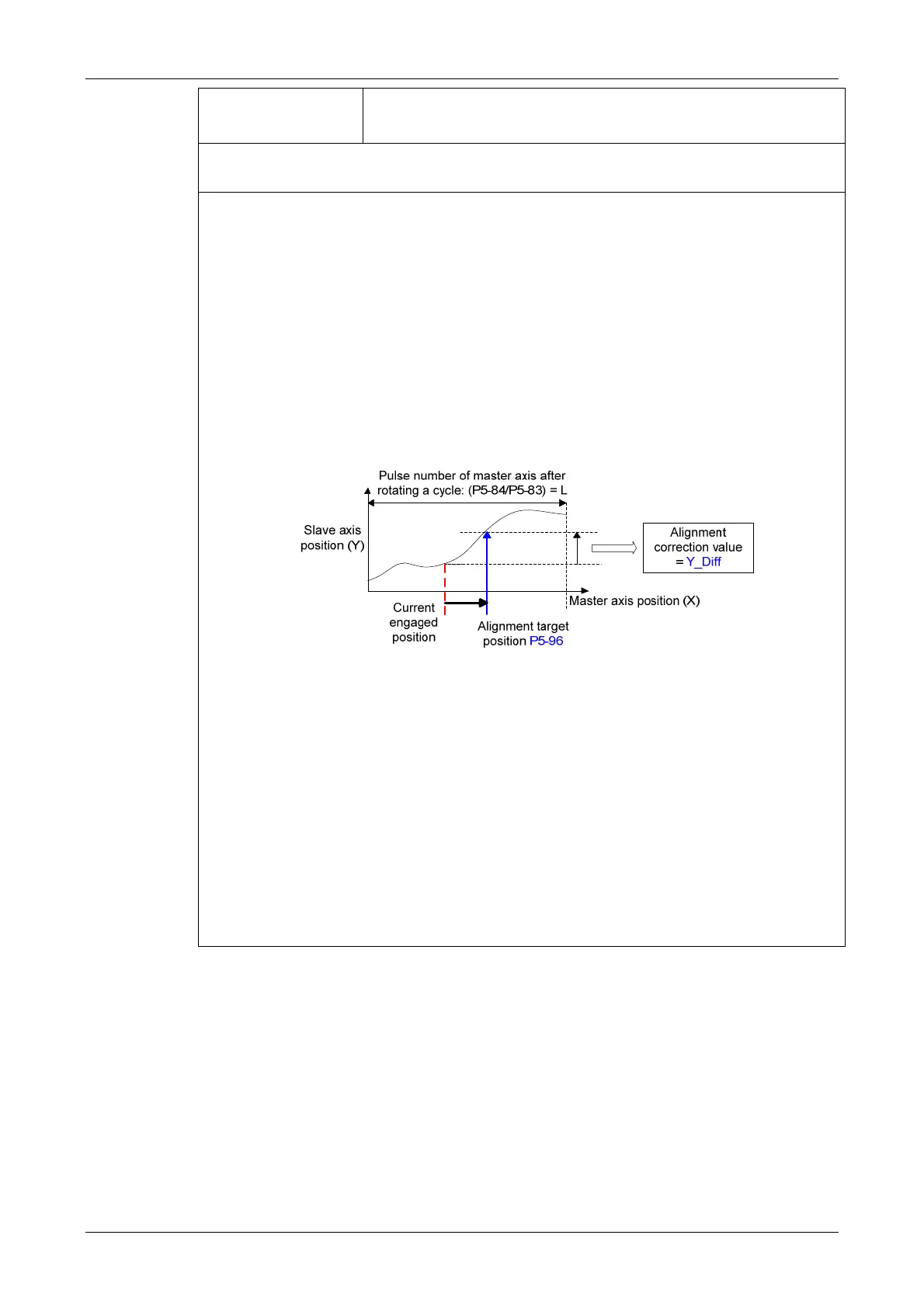

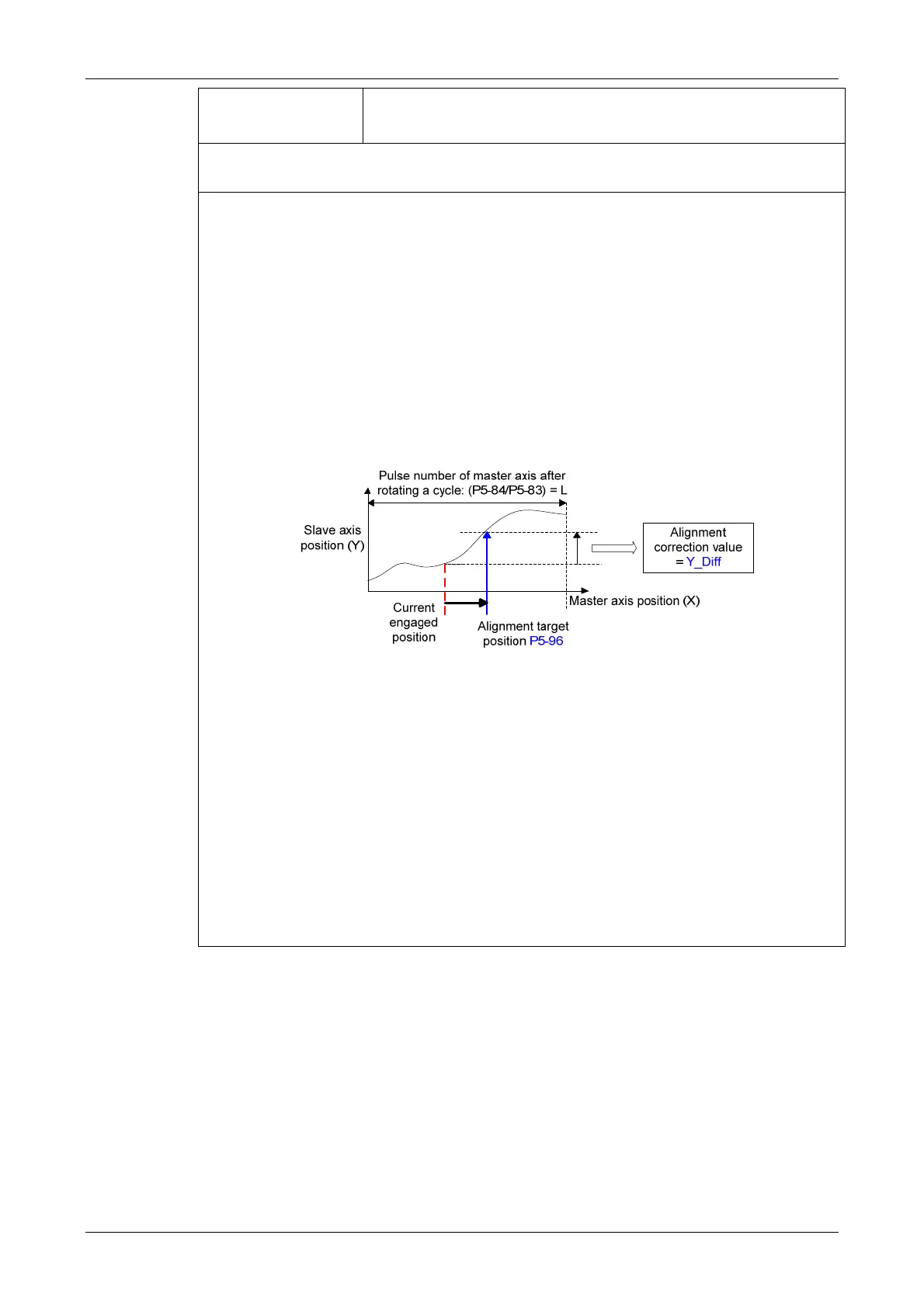

P5-96 (target position of alignment X); Unit: pulse number of

master axis = 0 ~ (P5-84/P5-83) – 1.

Monitoring variable 062(3Eh): It displays the current engaged position of master

axis (X)

This macro command can move the engaged position to the alignment target

position (X) when E-Cam is engaged. And write the alignment correction value into

the specified PR.

During E-Cam operation (When E-Cam is engaged), if desire to quickly align the E-

cam position to the mechanical referral point, sensor can be used to trigger DI.EVx

to execute this macro command.

After E-Cam alignment is completed, the engaged position will move to the new

position. The excess or not enough moving distance after E-Cam operates one

cycle is called alignment correction value. It will be written into PR specified by P5-

93.YX. PR incremental command can be used to compensate this value so that the

slave axis position will remain and offset the phase of E-Cam to align the referral

position of machine. For some applications, set value of P5-93.YX to 0 will do.

Please note that PR can be executed only when triggering the host controller.

*P5-93.UZ is able to limit the max. correction rate. The alignment target position

★ will be different from P5-96.

| alignment target position★ – current engaged position| / L <= P5-93.UZ %

*DI time delay compensation can be set via P5-94, it can correct the error caused

by different speed of motion.

When E-Cam moves from current position to the target one, it can rotate at forward

or reverse position. Due to the cyclic operation, it can reach the target position

either at forward or reverse direction. However, the moving distance between both

is usually different. Use available forward rate to plan the timing of forward and

reverse rotation.

*Available forward rate: The available max. proportion of forward path

Loading...

Loading...