Chapter 5 Trial Operation and TuningASDA-A2R Series

Revision December, 2014

5-7

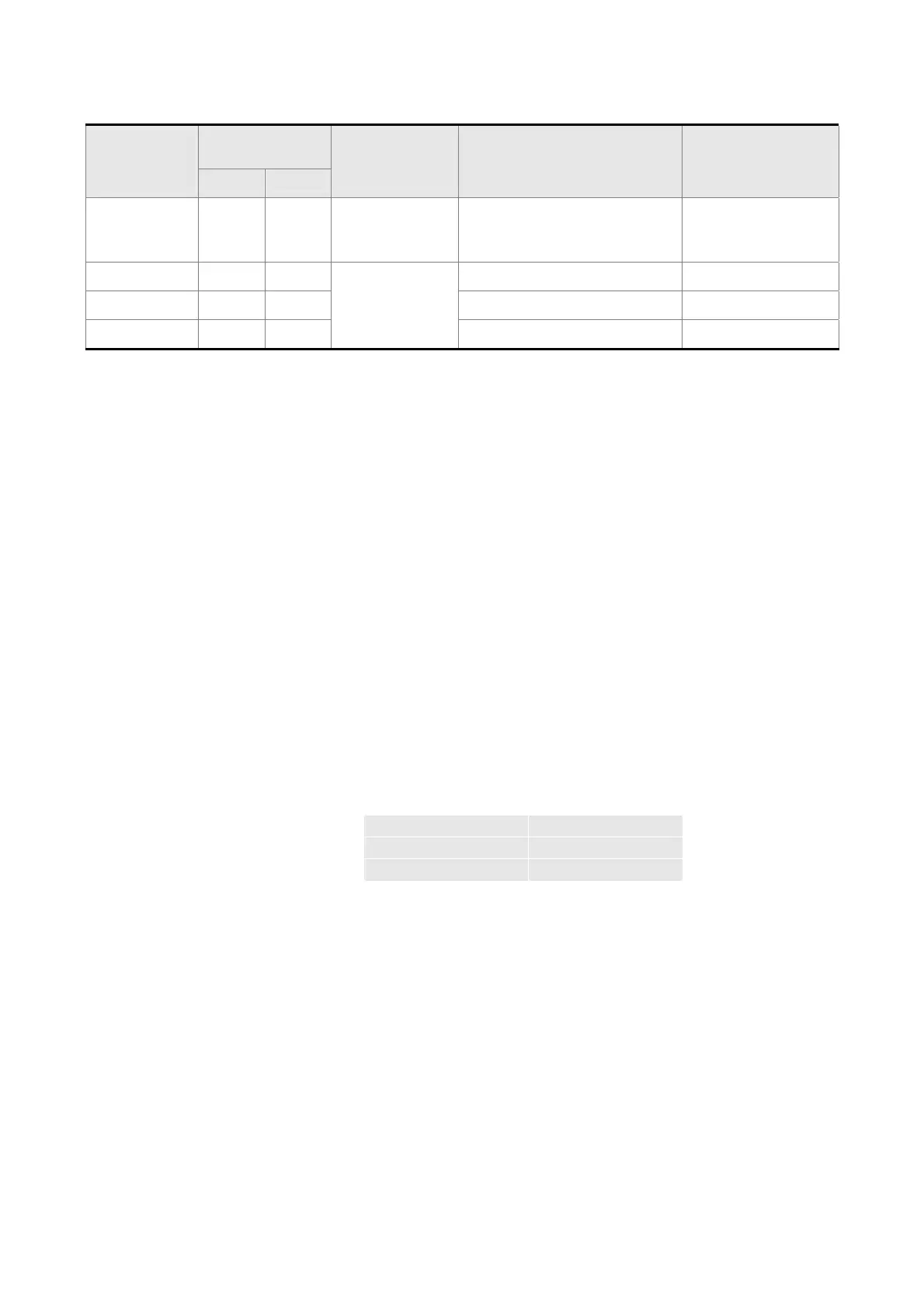

The speed command selection is determined by SPD0 and SPD1. See the table below.

Speed

Command

No.

DI signal of

CN1

Command

Source

Content Range

SPD1 SPD0

S1 0 0 External

analog

command

Voltage deviation between

V-REF and GND

-10V ~ +10V

S2 0 1

Register

parameter

P1-09 -60000 ~ 60000

S3 1 0 P1-10 -60000 ~ 60000

S4 1 1 P1-11 -60000 ~ 60000

0: means DI is OFF

1: means DI is ON

Register parameter

Permanent magnet synchronous rotary motor is -60000 ~ 60000; Setting value = setting

range x unit (0.1r/min).

Permanent magnet synchronous linear motor is -15999999 ~ 15999999; Setting value =

setting range x

sm /10

6

.

For example: P1-09 = +30000; the setting value of permanent magnet synchronous

rotary motor is +30000 x 0.1r/min = +3000r/min.

The setting value of permanent magnet synchronous linear motor =

+30000 x

s/m10

6

= 0.03m/s.

For example: P1-09 = +30000; Setting value = +30000 x 0.1r/min = +3000r/min

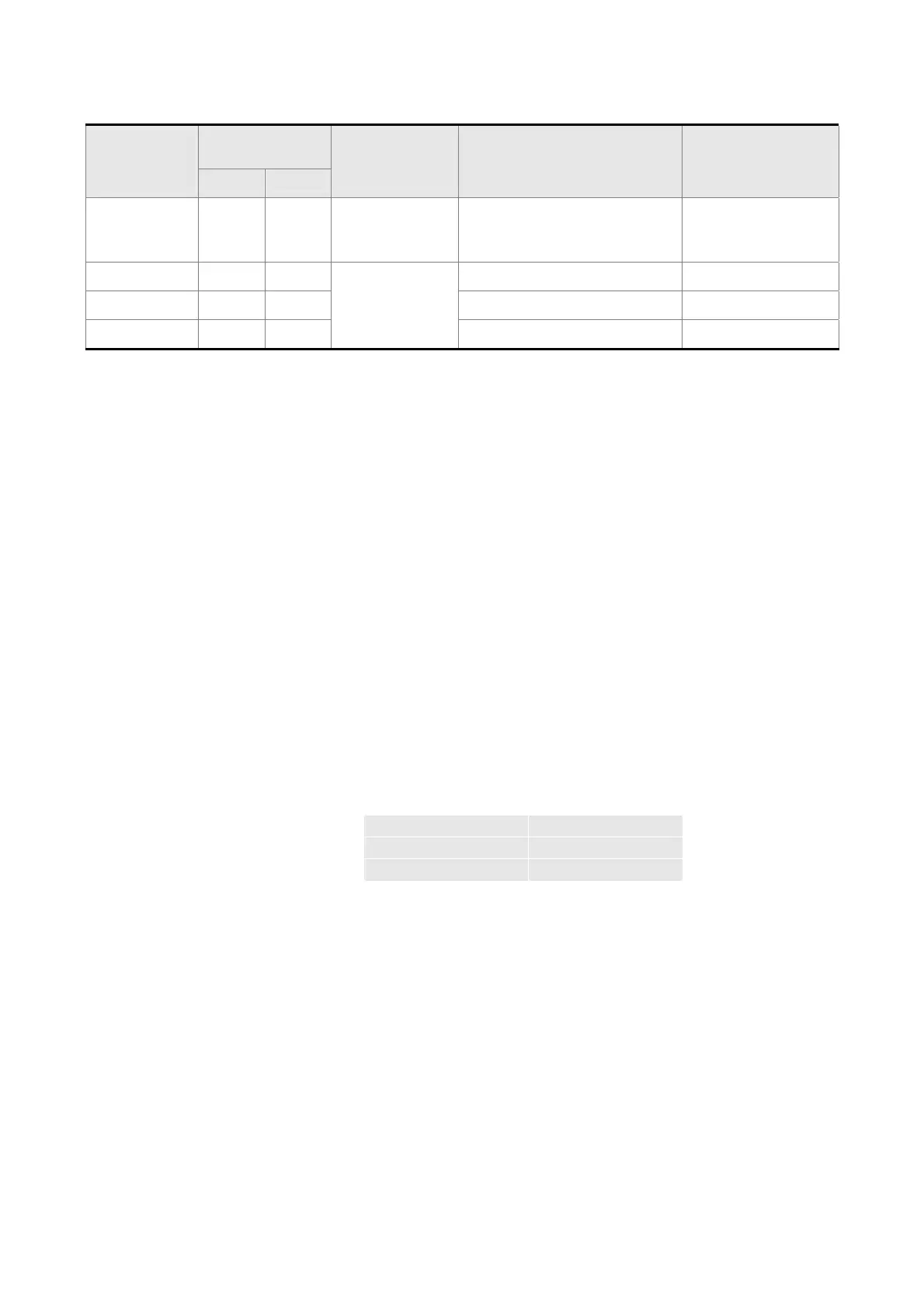

Command setting of speed register (Take rotary motor as the example)

Set parameter P1-09 to 30000.

Input command Rotation direction

Set parameter P1-10 to 1000. + CW

Set parameter P1-11 to -30000. - CCW

STEP 3:

(1) Users switch ON DI1 and Servo ON.

(2) Both DI3 (SPD0) and DI4 (SPD1), the speed command, are OFF, which means it

currently executes S1 command. The motor rotates according to analog voltage

command.

(3) When DI3 (SPD0) is ON, it means it currently executes S2 command (3000r/min). The

speed is 3000r/min at the moment.

(4) When DI4 (SPD1) is ON, it means it currently executes S3 command (100r/min). The

speed is 100r/min.

(5) When both DI3 (SPD0) and DI4 (SPD1) are ON, it means S4 command (-3000r/min)

is executed at the moment. The speed is -3000r/min.

Loading...

Loading...