Chapter 12 Setting of Motor Parameters ASDA-A2R Series

Revision December, 2014

12-13

The following common alarms are for reference.

:Auto detection of motor parameters is in error

Causes Checking Method Corrective Actions

When executing the

function of PM-01, if

the friction is too big,

motor is stuck or

entering wrong

resolution and pitch

pole, this alarm will

occur.

1. Check if motor pole pitch,

encoder resolution and

encoder type are entered

correctly.

2. Check if motor is stuck during

detection.

3. Check if the motor friction is

too big.

4. Check if the feedback of linear

scale is abnormal, the

connection is breakdown, the

scale is not installed properly

or there is noise interference.

1. Enter the value which is the

same as the actual one and

activate the detection again.

2. The rotary motor will rotate at

forward and reverse direction

for one magnetic cycle during

detection. The linear motor

will move for a pitch forward

and backward. Please

preserve the moving distance

before detection.

3. Chang another motor with

more power.

4. Correct the problem of linear

scale.

Check if the feedback of linear scale works properly through PC software.

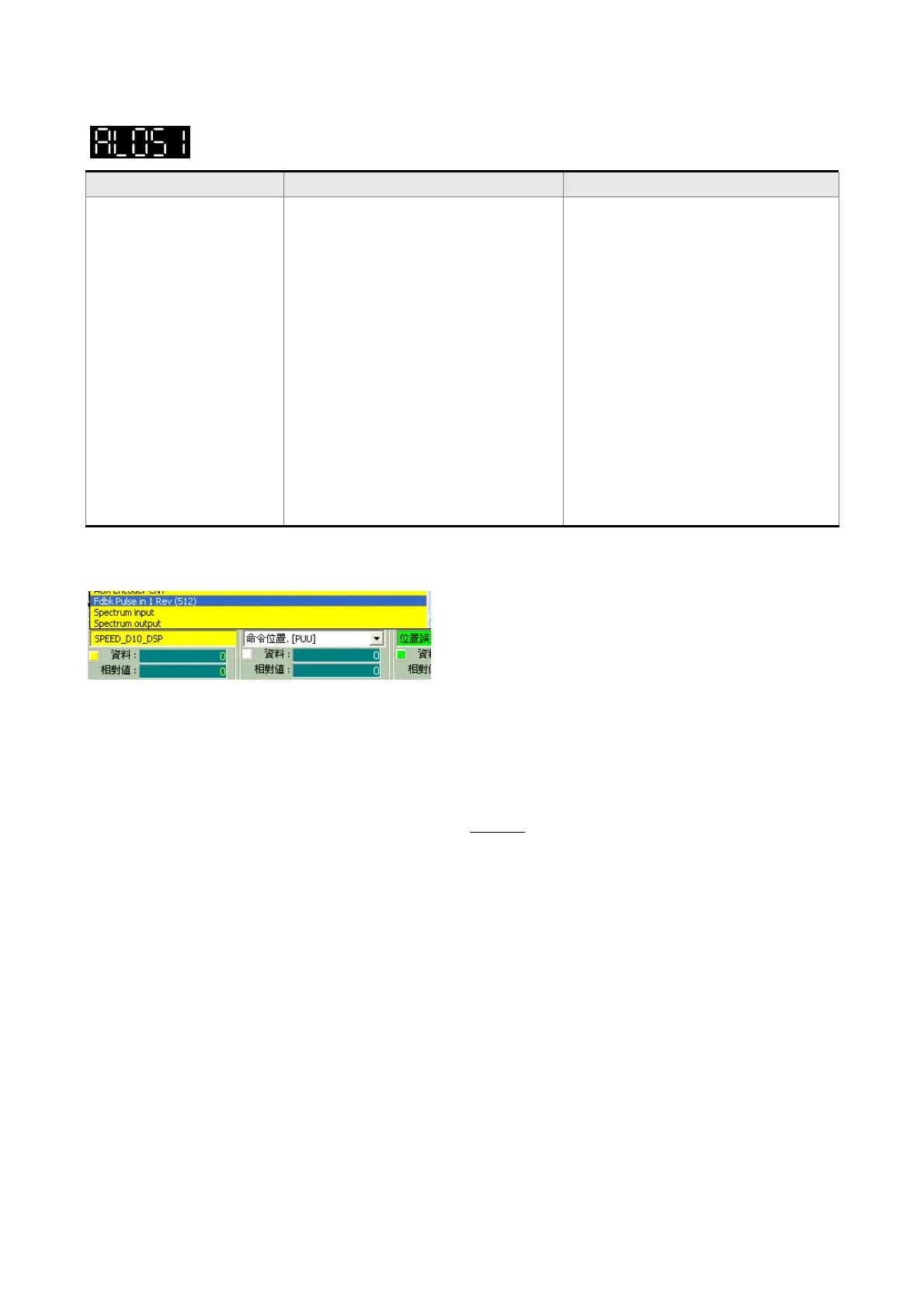

In monitor variable mode, press the SHIFT Key to pop up the menu. Select FDBK PULSE

IN 1REV (512) and check 32BIT. This is the actual feedback pulse of linear scale

(quardruple frequency). Manually move the fixed distance of linear motor. Observe the

change of variables to see if the moving distance matches the linear scale resolution.

For example, the linear scale resolution is 1um. If the linear motor is moved for 0.1m, the

value of FDBK PULSE IN 1REV (512) will be

100000

10*1

1.0

6

pulse number.

If it has excessive error, please check if the linear scale has the problem that mentioned

above.

Loading...

Loading...