ASDA-B2 Chapter 5 Trial Operation and Tuning

Revision May, 2018 5-19

5.5.8 Tuning in Manual Mode

The selection of position / speed response frequency should be determined by the

machinary stiffness and application. General speaking, the high-frequency machinary or

the one requries precise processing needs the higher response frequency. However, it

might easily cause the resonance. And the stronger stiffness machinary is needed to avoid

the resonance. When using the unknown resonse frequency machinary, users could

gradually increase the gain setting value to increase the resonse frequency. Then,

decrease the gain setting value until the resonance exists. The followings are the related

descriptions of gain adjustment.:

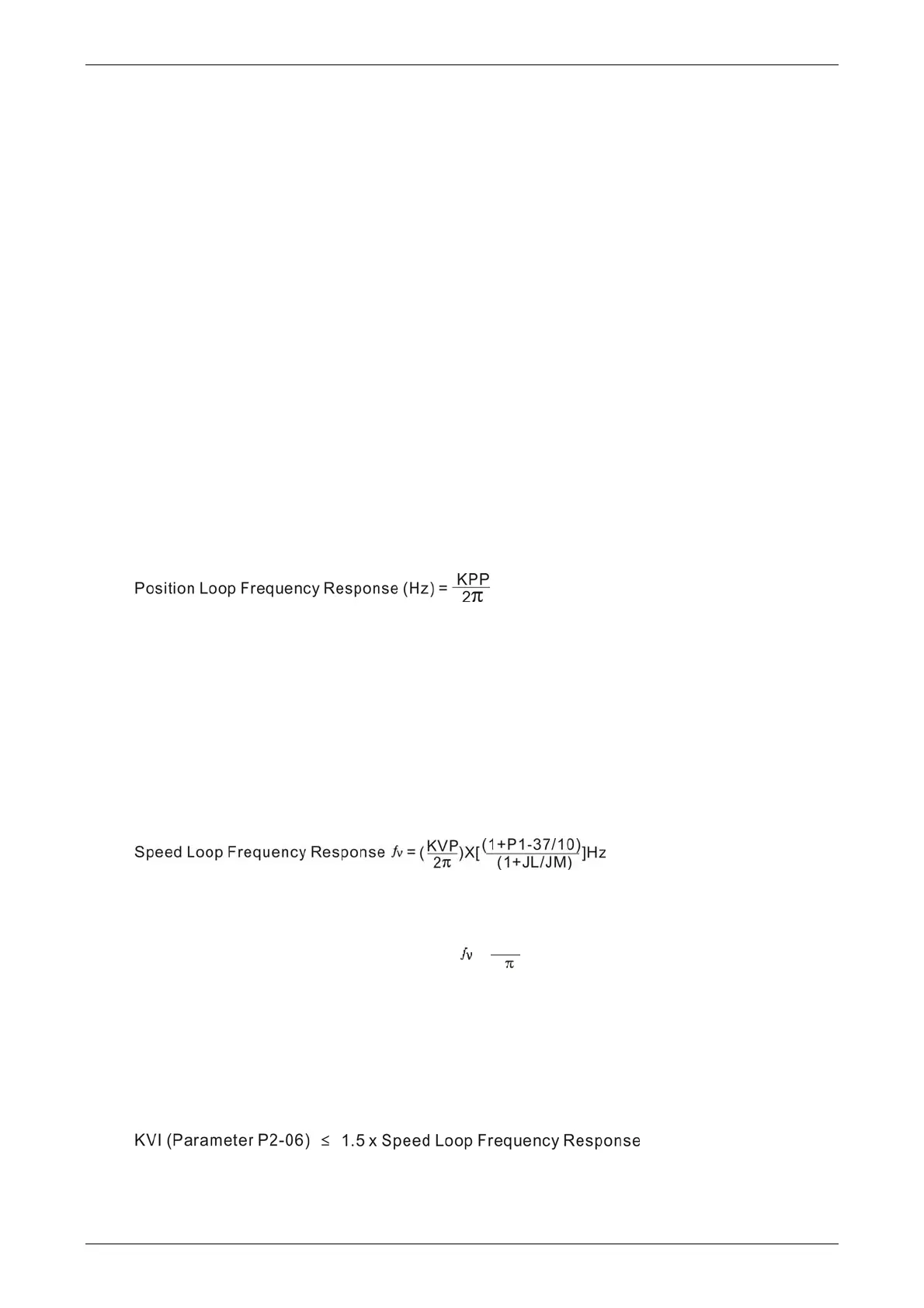

Position control gain (KPP, parameter P2-00)

This parameter determines the response of position loop. The bigger KPP value will

cause the higher response frequency of position loop. And it will cause better

following error, smaller position error, and shorter settling time. However, if the value

is set too big, the machinery will vibrate or overshoot when positioning. The

calculation of position loop frequency response is as the following:

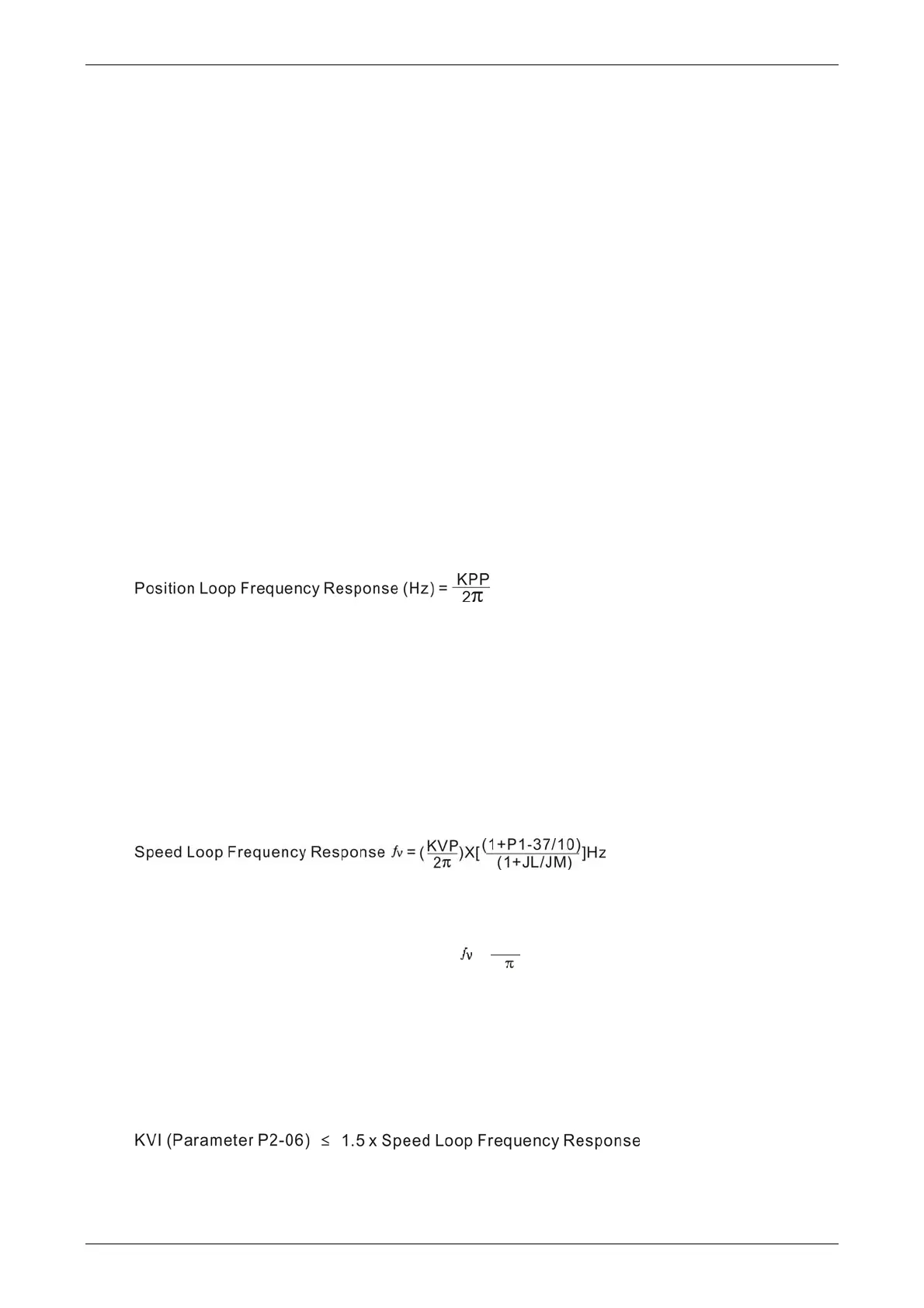

Speed control gain (KVP, parameter P2-04)

This parameter determines the response of speed loop. The bigger KVP value will

cause the higher response frequency of speed loop and better following error.

However, if the value is set too big, it would easily cause machinery resonance.

The response frequency of speed loop must be 4~6 times higher than the response

frequency of position loop. Otherwise, the machinery might vibrate or overshoot when

positioning. The calculation of speed loop frequency response is as the following:

When P1-37 (estimation or setting) equals the real inertia ratio (JL/JM), the real

speed loop frequency response will be:

= Hz

KV

2

Speed integral compensation (KVI, parameter P2-06)

The higher the KVI value is, the better capability of eliminating the deviation will be.

However, if the value is set too big, it might easily cause the vibration of machinery.

It is suggested to set the value as the following:

JM: Motor Inertia

JL: Load Inertia

P1-37: 0.1 times

Loading...

Loading...