Chapter 16 PLC Function Applications│CP2000

16-102

API

MODRW

Modbus data read/write

150

P

Bit device Word device

16-bit command (5 STEP)

MODRW Continuous

execution type

MODRW

P

Pulse

execution type

32-bit command

- - - -

Flag signal: M1077 M1078 M1079

X Y M K H KnX KnY KnM T C D

S1

* *

*

S2

* *

*

S3

* *

*

S

*

n

* *

*

S1: online device address. S2: communications function code. S3: address of

data to read/write. S: register for data to be read/written is stored. N: length of data

to be read/written.

COM1 must be defined as controlled by the PLC (set P9-31 = -12) before using

this command, and the corresponding communications speed and format must

also be set (set P09-01 and P09-04). S2: communications function code.

Currently only supports the following function code; the remaining function code

cannot be executed.

Function Description

H 02 Input read

H 03 Read word

H 06 Write single word

H 0F Write multiple coils

H10 Write single word

After executing this command, M1077, M1078 and M1079 will be immediately

changed to 0.

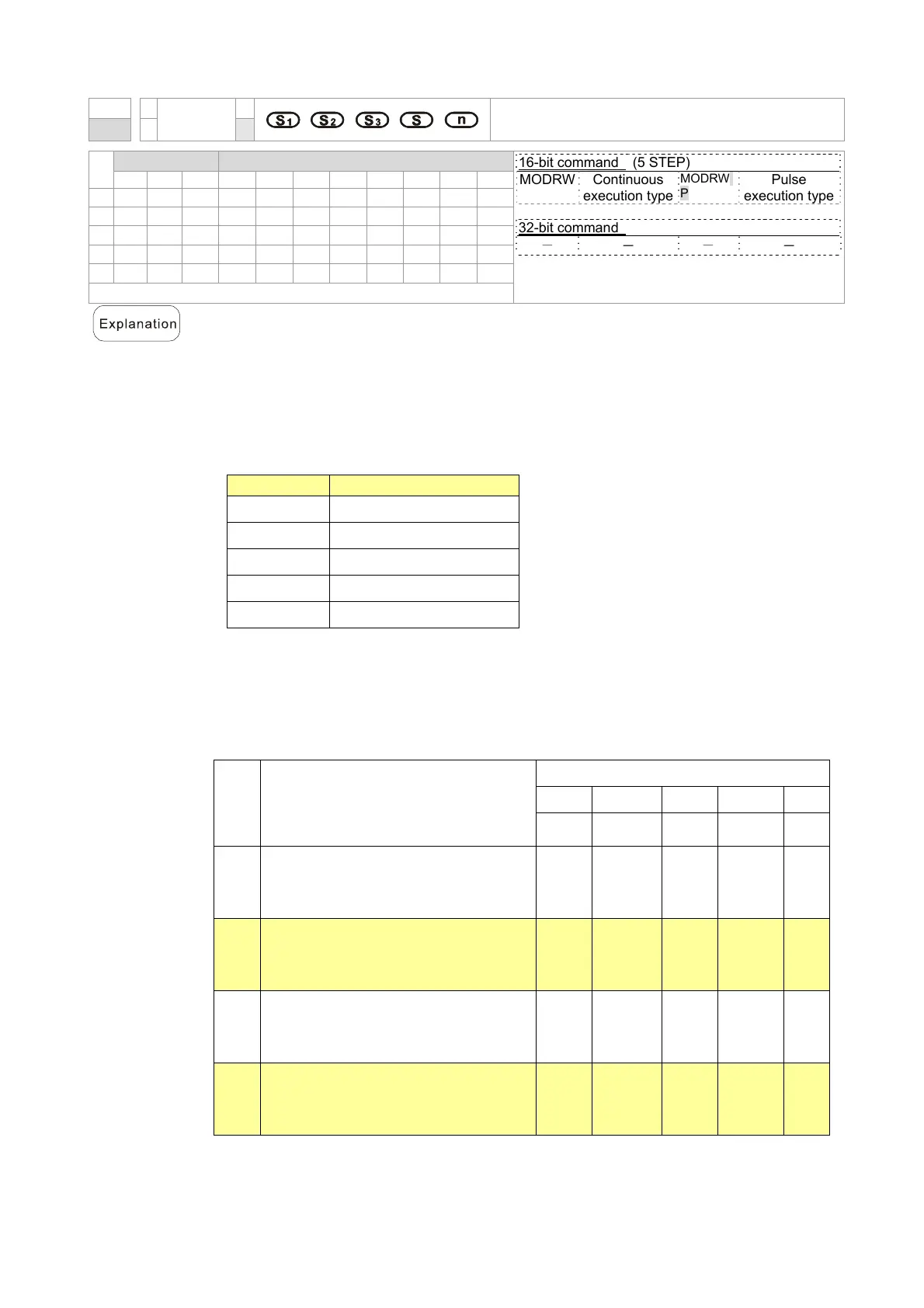

As an example, when CP2000 must control another converter and PLC, if the

converter has a station number of 10 and the PLC has a station number of 20, see

the following example:

Control slave device converter

Seria

l No.

Example

MODRW command

S1 S2 S3 S4 n

Node ID

Function

code

Address Register

Length

1

Reads 4 sets of data comprising the

converter slave device parameters

P01-00 to P01-03, and saves the read

data in D0 to D3

K10 H3 H100 D0 K4

2

Reads 3 sets of data comprising the

converter slave device addresses

H2100 to H2102, and saves the read

data in D5 to D7

K10 H3 H2100 D5 K3

3

Reads 3 sets of data comprising the

converter slave device parameters

P05-00 to P05-03, and writes the

values as D10 to D12

K10 H10 H500 D10 K3

4

Writes 2 sets of data comprising the

converter slave device addresses

H2000 to H2001, and writes the values

as D15 to D16

K10 H10 H2000 D15 K2

Loading...

Loading...