SGX VIBRATOR MOTOR

15 Jun 12 7-25

HyperPoolShaker

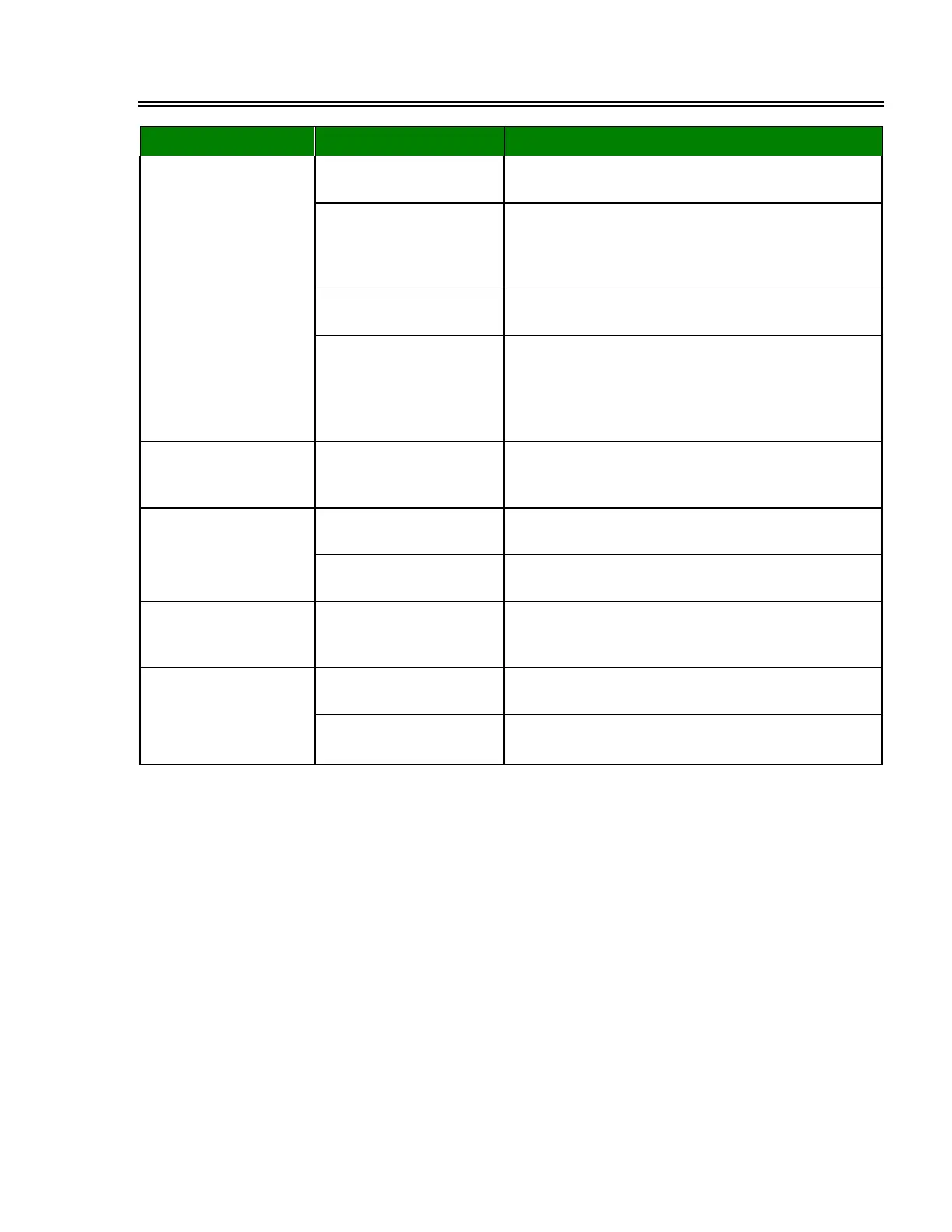

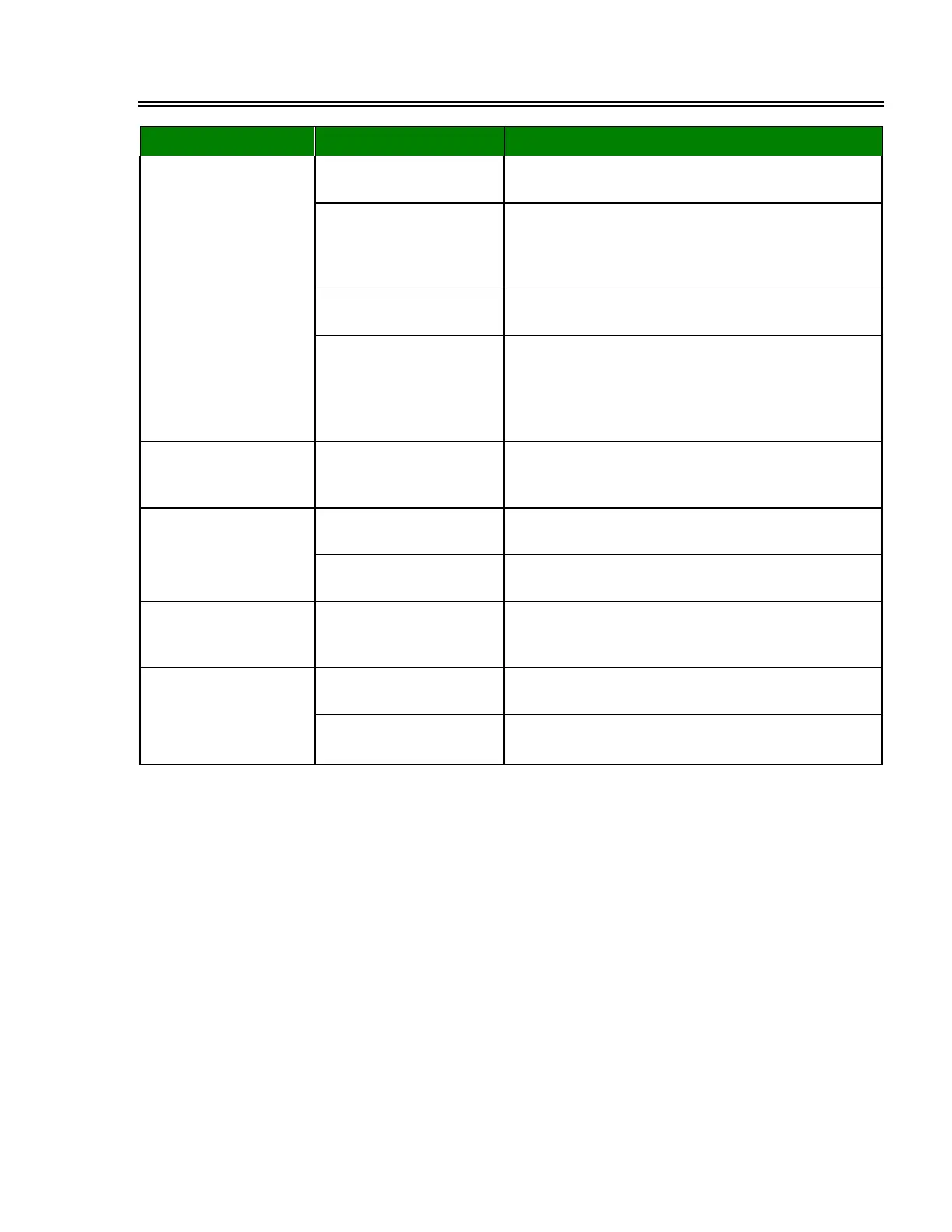

Trouble Possible Cause Corrective Action

Excessive current

draw

Incorrect supply

voltage

Verify that supply voltage agrees with motor

data plate.

Incorrect thermal

overload

Check that thermal overload is capable of

handling full load current. Replace overload, if

inadequate (see motor data sheet for load

data).

Mounting hardware

loose

Check security of mounting hardware. Tighten

as required.

Vibrating motion of

motor and related

components restricted

Verify that shipping brackets have been

removed / disengaged as required. Verify that

float mounts are in good condition. Verify that

solids are not preventing motion of the screen

frame. Correct all defects.

Surface temperature

too high*

Excessive buildup of

process material on

motor case

Wash off buildup from motor case.

Excessive noise

Loose hardware

Check security of all external and internal

hardware. Tighten as required.

Defective bearing

Replace both bearings in accordance with

Bearing Replacement.

Motor turns too

slowly

Incorrect supply

voltage or line

Check that supply voltage and line frequency

agree with motor data plate. Frequency must

Motors not

synchronized (dual

motors only)

No electric power to

Check that supply voltage is connected to both

Incorrect electrical

connections

Confirm that electrical connections are in

accordance with the instructions in this section.

* Derrick vibrator motors run with higher surface temperatures than standard industrial motors.

Refer to the maximum temperature rise indicated on the motor data plate attached to the motor

case or the motor data sheet included in this manual.

Loading...

Loading...