5 95-87142.2

opERation

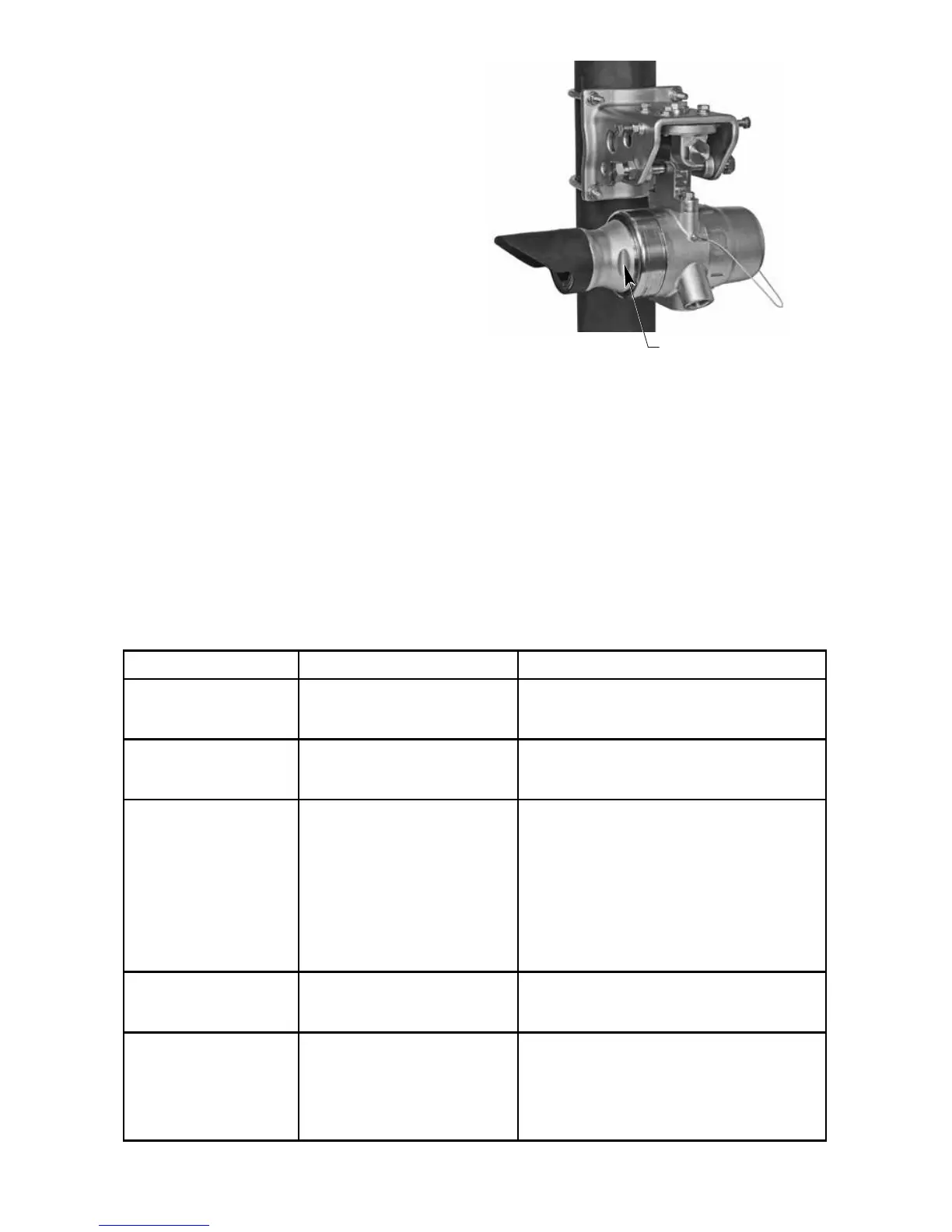

INTERNAL MAGNETIC SWITCH /

CALIBRATION LINE TERMINAL

An internal magnetic switch is provided for

resetting latched alarms and initiating field zero

calibration. See Figure 2 for switch location.

The same functions can be accomplished

remotely by installing a switch (momentary

closure) between the CAL and 0V COM

terminals on the LS2000 receiver. Momentary

switch activation will reset alarms, while holding

the switch closed for 3 seconds or longer (not

to exceed 30 seconds) will start the calibration

sequence. The LEDs will begin flashing green

(5 Hz) when the reset criteria have been met and

will change to flashing yellow (5 Hz) when the

calibration period has been met (>3 seconds,

<30 seconds). The device will reset if the switch

is released during a flashing green LED and will

enter calibration if the switch is released during a

flashing yellow LED.

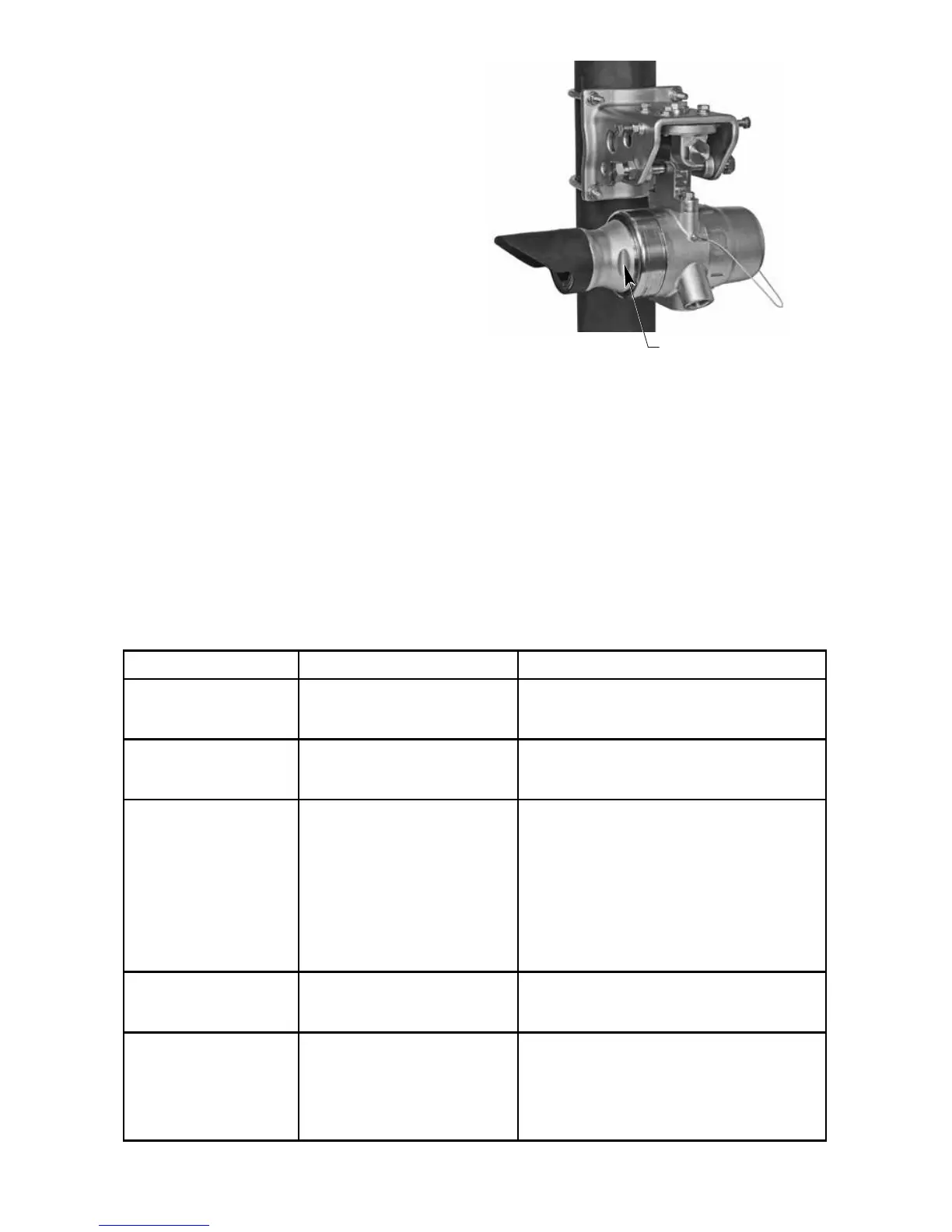

MODULE IDENTIFICATION

See Figure 3 for identification of the transmitter

and receiver modules. The functional and

electrical characteristic differences of the two

devices are described in Table 2.

FACTORY RESET COMMAND

The LS2000 provides a factory reset command

that sets all user configurable parameters

back to their default settings. This command

can be accessed via HART or MODBUS

communication.

PLACE CALIBRATION MAGNET HERE

TO ACTIVATE INTERNAL REED SWITCH

A2648

Figure 2—Location of Internal Magnetic Switch

on Receiver Module

Table 2—Functional and Electrical Comparison of Transmitter and Receiver

Characteristic Transmitter Receiver

Functional Description Contains a xenon flash lamp,

and generates optical energy to

enable hydrocarbon detection.

Contains opto-electronics, signal processing,

output drivers, and diagnostic electronics.

Electrical Connections Connections for power, HART,

RS-485, Communication Link.

Connections for power, 4-20 mA, HART,

RS-485, relay contacts (optional),

Communication Link, and calibration/reset.

Onboard LED Indicators Indicates device status.

Green indicates normal

operation.

Yellow indicates fault condition.

When the Communication Link

is used, the transmitter LED

operation matches receiver

LED operation, including alarm

status.

Indicates normal, alarm, fault, and calibration

status.

Green indicates normal operation. Blinking red

indicates low gas alarm condition.

Steady red indicates high gas alarm condition.

Yellow indicates system fault. See Tables 4 and

5 for details.

LED operation for fault status is non-latching.

LED operation for gas alarms is configurable

for latching/non-latching.

Magnetic Calibration

Switch (See Figure 2 for

switch location.)

NA Momentary activation provides reset function

for latched alarm outputs. Activation for longer

than 3 seconds will initiate zero calibration.

Adjustable Settings Programmable IR signal intensity

and heater operation. HART

or MODBUS communication is

required to change the factory

default settings.

Factory calibrated for methane, propane, and

butane, 0-5 LFL-meters full scale. Default gas

depends on model. See Table 3 for receiver

factory default settings. HART or MODBUS

communication is required to change the

factory default settings.

Loading...

Loading...