25 95-87142.2

11. Verify alignment using the Alignment Tool.

The Vertical alignment may have shifted

slightly due to tightening of the 4 Horizontal

locking bolts pulling the Detector Mounting

Assembly up. Adjust the vertical alignment if

needed using the Vertical Adjustment Bolts.

12.

When proper alignment has been achieved,

tighten the Vertical Adjustment Bolts

and Locking Nuts to 90 ft-lbs (122 N•m)

maximum, being careful to tighten each

bolt evenly against each other to prevent

torquing of the Detector Mounting Assembly.

The Receiver is now secured vertically and

aligned with the Transmitter.

13. Repeat the alignment procedure for the

transmitter module (steps 3 to 12).

14. Re-check the alignment one final time using

the alignment tool and adjust as needed.

15. Remove the Alignment Tool and re-install the

brow.

16. Bypass all external gas alarm devices that

are connected to the receiver outputs, and

then apply 24 Vdc power to the modules.

17. Upon completion of warm-up mode

(approximately 2 minutes or less), the

receiver should produce a 4 mA output

signal and a green LED indication. If not,

the required zero calibration step below may

resolve this issue.

18. For installations with module separation

distances between 5 and 40 meters, install

the aperture as described in the “Aperture Kit

for Short Range Applications” section.

19. Perform a zero calibration. (Refer to “Zero

Calibration” in the Calibration section of this

manual.) Any faults that may be present as

a result of the alignment process should be

cleared.

NOTE

The LS2000 transmitter lamp output

intensity is automatically optimized

during the zero calibration process if the

communication link wires are attached

between transmitter and receiver. If

no communication link is installed, the

transmitter lamp output can be adjusted

via MODBUS or HART connection to

the transmitter. This adjustment is rarely

needed. (See “Transmitter Lamp Voltage”

section for more information.)

20. Proper operation should be confirmed by

bypassing all system alarms, then placing

an optical test film (sold separately) into the

light beam and checking for the appropriate

4-20 mA output level or relay actuation.

The LS2000 test film packet consists

of five separate test films. Table 7 shows

the response of the different LS2000 gas

settings to each of the five test films. Alarm

conditions, if present, should clear when the

test film is removed from the beam.

21.

Confirm proper operation by completely

blocking the light beam with a solid object

such as a piece of cardboard until a beam

block fault is signaled by the appropriate

4-20 mA output level or relay action (default

delay is 60 seconds). The fault should clear

when the blocking device is removed from

the beam.

22. When Basic Alignment and Zero Calibration

have been successfully completed, a green

LED should be displayed on the receiver

module and the analog signal output level

should be 4.0 milliamperes.

APERTURE KIT FOR SHORT RANGE

APPLICATIONS

The Short Range Aperture Kit enables

successful application of the LS2000 gas

detector at short separation distances (5-15

meters for the short range model and 30-40

meters for the long range model). The aperture

is made of aluminum and is included with the

LS2000.

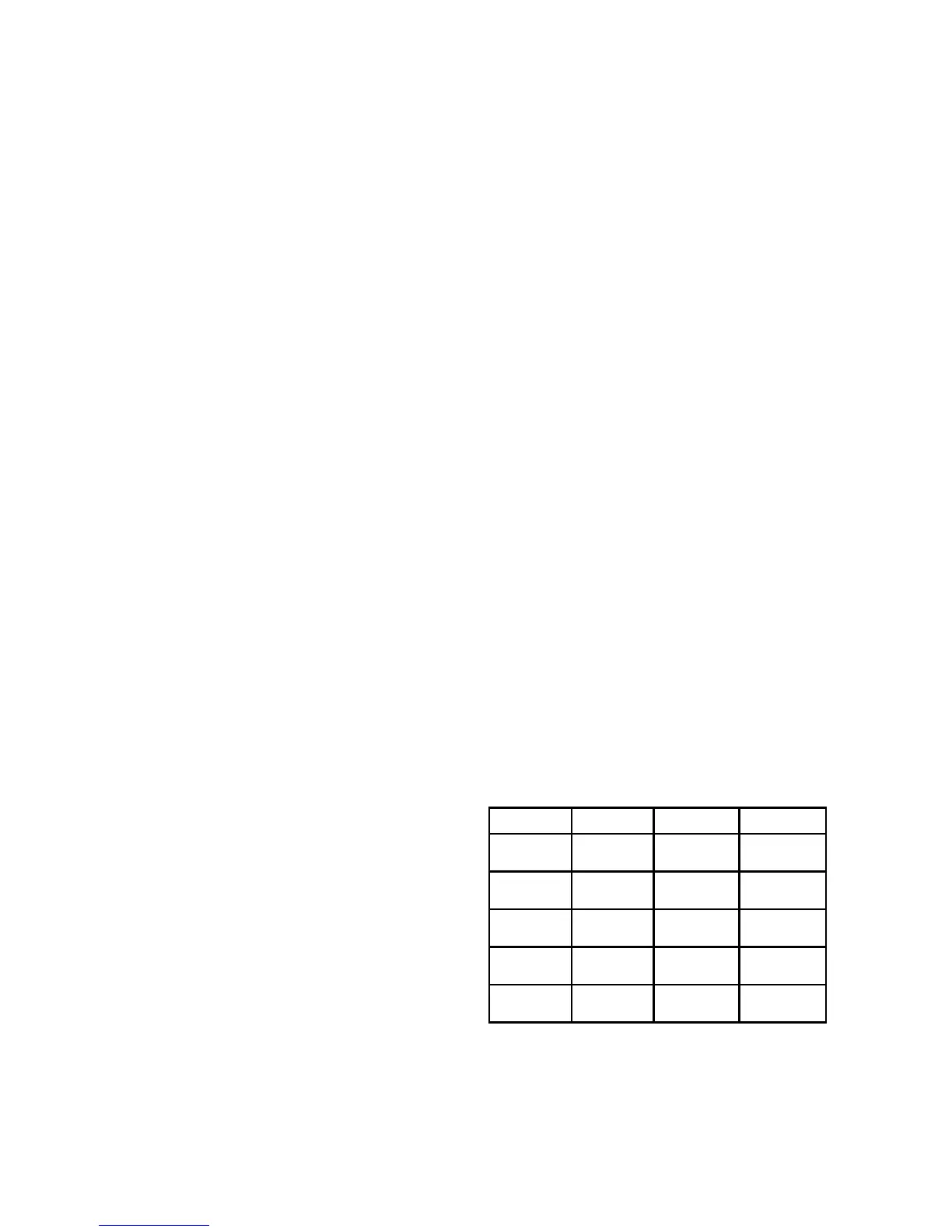

Table 7—Typical System Response

*

in LFL-M (% Full Scale)

Using Gas Test Films

Test Film Methane Butane Propane

1

0.6

(12%)

1.1

(22%)

1.3

(26%)

2

1.5

(29%)

2.3

(46%)

2.6

(52%)

3

2.5

(50%)

3.6

(72%)

3.9

(78%)

4

3.7

(74%)

4.9

(98%)

5.4

(108%)

5**

5.0

(100%)

6.0

(120%)

6.0

(120%)

*Accuracy = ±0.2 LFL-M or ±15% LFL-M from typical system

response, whichever is greater.

**A HART handheld device is needed to read over-range values.

Loading...

Loading...