23 95-87142.2

aliGnmEnt

OVERVIEW

The LS2000 modules must be properly aligned

before normal operation will be attained.

NOTE

Refer to the FM, ATEX, or IECEx Appendix

for information regarding the effect of

misalignment on system accuracy.

IMPORTANT

Upon completion of system alignment,

ensure that ALL bolts on the LS2000

mounting and alignment bracket are

properly tightened.

EQUIPMENT REQUIRED

1. Properly installed and powered LS2000

system (transmitter and receiver). Easy

access to both modules is highly

recommended.

2.

LS2000 Alignment Tool. The alignment tool

is recommended for use in commissioning all

LS2000 systems. The following instructions

cover the use of the Alignment Tool.

3. 9/16 inch wrench.

4. 15/16 inch wrench.

5. For installations with short separation

distances (5-15 meters for the short range

model and 30-40 meters for the long range

model), the short range aperture kit (supplied)

is typically needed. Refer to “Aperture Kit

for Short Range Applications” section in this

manual for details.

ALIGNMENT PROCEDURE

1. Ensure that the system modules are located

within the specified separation range and

securely fixed to the support structures.

Bypass all external gas alarm devices that are

connected to the receiver outputs.

2. Ensure that the system modules are installed

with their windows at approximately the same

height above grade. Each module should be

roughly aligned to face in the direction of the

other module.

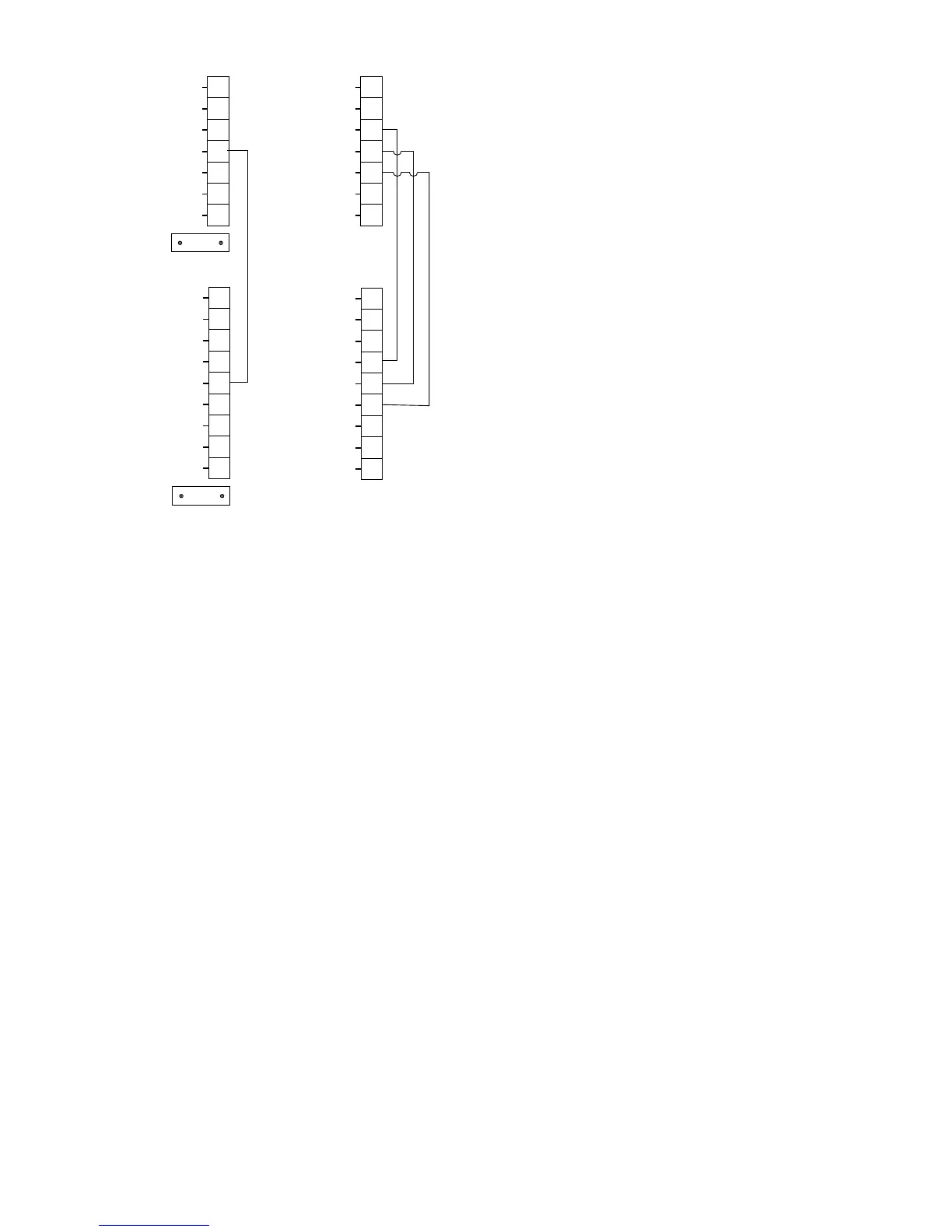

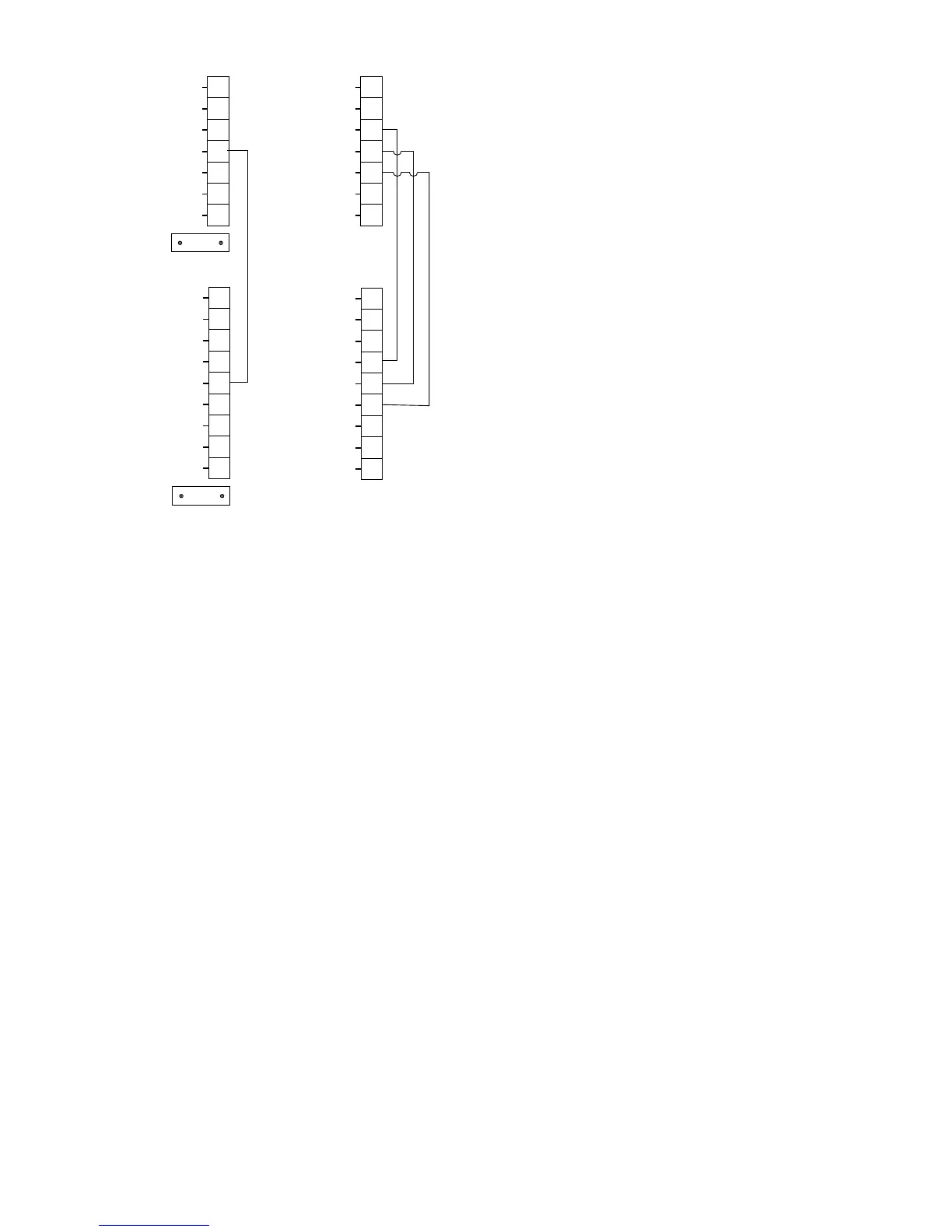

3. Loosen the Horizontal and Vertical

Adjustment Bolts on the mounting and

alignment bracket using the 9/16” wrench

for the Horizontal Adjustment Bolts and the

15/16” wrench for the Vertical Adjustment

Bolts. See Figure 21.

4. Loosen the four Horizontal Locking Bolts on

top of the mounting and alignment bracket

using a 9/16” wrench, then retighten until just

snug against the top plate of the Detector

Mounting Assembly. The Detector Mounting

Assembly should still be able to rotate on

its axis when adjusting the Horizontal

Adjustment Bolts. If not, slightly loosen the

four Horizontal Locking bolts.

5. Remove the brow by gently working side to

side while pulling forward.

A2667

+4-20mA

INTR GND

RS-485 A

INTR A

SHIELD

SHIELD

+24 VDC

SPARE

+24 VDC

11

12

13

14

15

16

17

18

19

–4-20mA

CAL

RS-485 B

INTR B

SHIELD

SHIELD

0V COM

0V COM

0V COM

1

2

3

4

5

6

7

8

9

HART

CAUTION: DO NOT CONNECT THE COMMUNICATION LINK “INTR GND”

TERMINAL TO POWER SUPPLY COMMON OR ANY OTHER

Loading...

Loading...