95-8704

6

2.7

• Although IR detectors are less affected by smoke

than other detectors, the X3301 should not be

placed where rising combustion products can

obscure its vision. If smoke is expected before

fire, smoke or other alternative detectors should

be used in conjunction with the X3301. For

indoor applications, if dense smoke is expected

to accumulate at the onset of a fire, install

the detector on a side wall at least a few feet

(approximately 1 meter) down from the ceiling.

• If possible, fire tests can be conducted to verify

correct detector positioning and coverage.

• For ATEX/IECEx installations, the X3301 Flame

Detector housing must be electrically connected

to earth ground.

DETECTOR ORIENTATION

Refer to Figure 2 and ensure that the

o

i

plate

will be oriented as shown when the X3301 is

installed and sighted. This will ensure proper

operation of the

o

i

system and will also minimize

the accumulation of moisture and contaminants

between the

o

i

plate and the viewing windows.

IMPORTANT

If removed, the

o

i

plate must be securely

tightened to ensure proper operation of

the

o

i

system (40 oz./inches [28.2 N

.

cm]

recommended).

PROTECTION AGAINST MOISTURE DAMAGE

It is important to take proper precautions during

installation to ensure that moisture will not come

in contact with the electrical connections or

components of the system. The integrity of the

system regarding moisture protection must

be maintained for proper operation and is the

responsibility of the installer.

If conduit is used, we recommend installing drains,

according to local codes, at water collection points

to automatically drain accumulated moisture. It is

also recommended to install at least one breather,

according to local codes, at upper locations to

provide ventilation and allow water vapor to escape.

Conduit raceways should be inclined so that

water will flow to low points for drainage and

will not collect inside enclosures or on conduit

seals. If this is not possible, install conduit drains

above the seals to prevent the collection of water

or install a drain loop below the detector with a

conduit drain at the lowest point of the loop.

Conduit seals are not required for compliance

with explosion-proof installation requirements, but

are highly recommended to prevent water ingress

in outdoor applications. Units with M25 threads

must use an IP66 washer to prevent water ingress.

WIRING PROCEDURE

Wire Size and Type

The system should be wired according to local

codes. The wire size selected should be based

on the number of detectors connected, the supply

voltage and the cable length. Typically 16 AWG, 2.5

mm

2

shielded cable is recommended. Wires should

be stripped 3/8 inch (9 mm). A minimum input

voltage of 18 Vdc must be present at the X3301.

NOTE

Refer to “Power Consumption” in the

“Specications” section of this manual.

The use of shielded cable is required to protect

against interference caused by EMI and RFI.

When using cables with shields, terminate

the shields as shown in Figures 7 through 12

and Figure 15. Consult the factory if not using

shielded cable.

In applications where the wiring cable is installed

in conduit, the conduit must not be used for wiring

to other electrical equipment.

If disconnection of power is required, separate

disconnect capability must be provided.

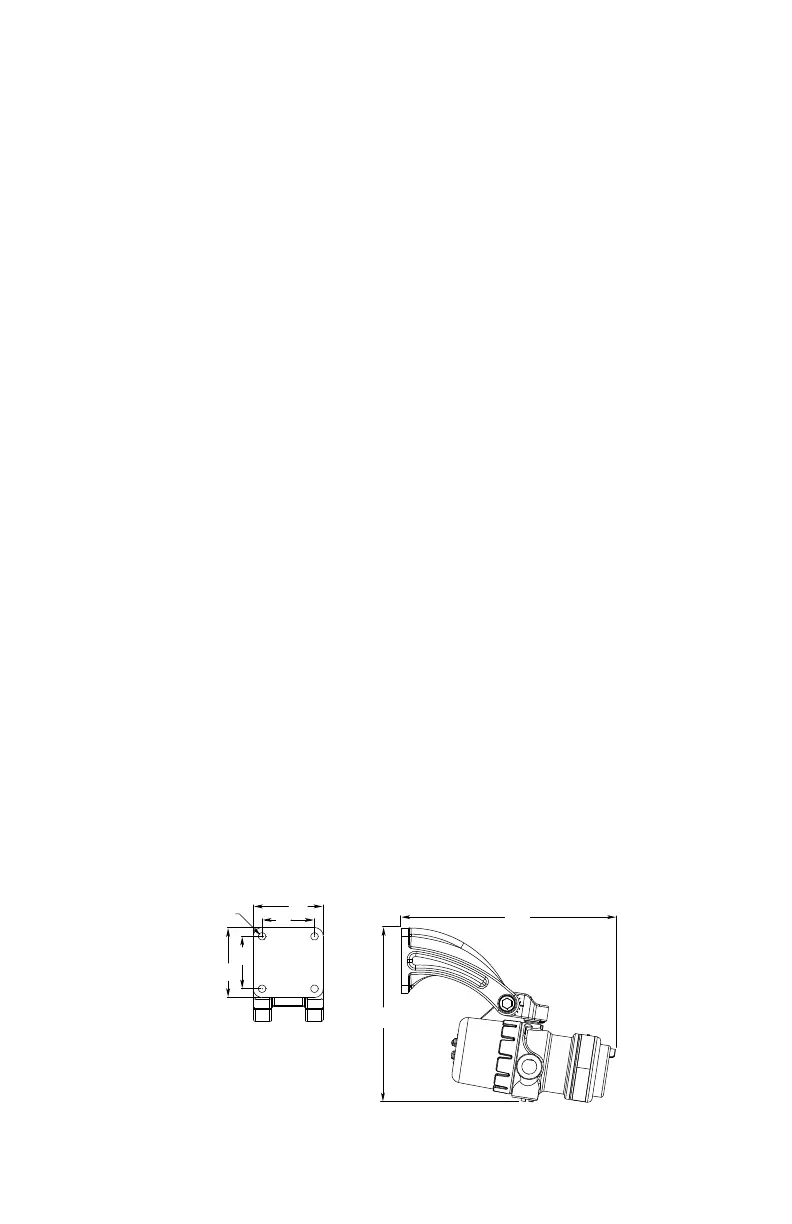

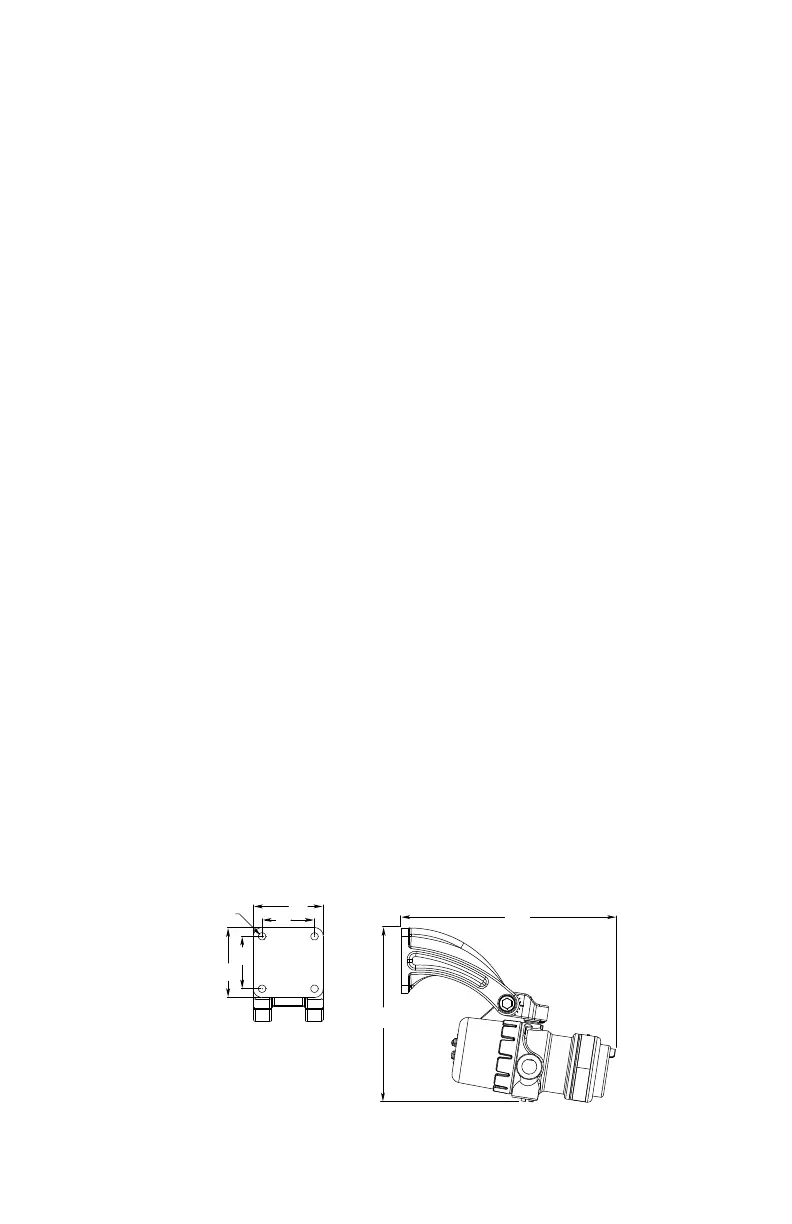

13.1

(33.3)

10.6

(27.0)

(10.2)

4.0

(10.2)

3.0

(7.6)

3.0

(7.6)

4X ø0.42

(1.1)

NOTE: THIS ILLUSTRATION SHOWS THE

DETECTOR MOUNTED AT THE 10° MINIMUM.

THESE DIMENSIONS WILL CHANGE BASED

ON THE DETECTOR’S MOUNTING ANGLE.

Figure3—Q9033 Mounting Arm without Collar Attachment Dimensions in Inches (cm)

(See Figure 1 for Correct Detector Orientation.)

Loading...

Loading...