5

© 2000

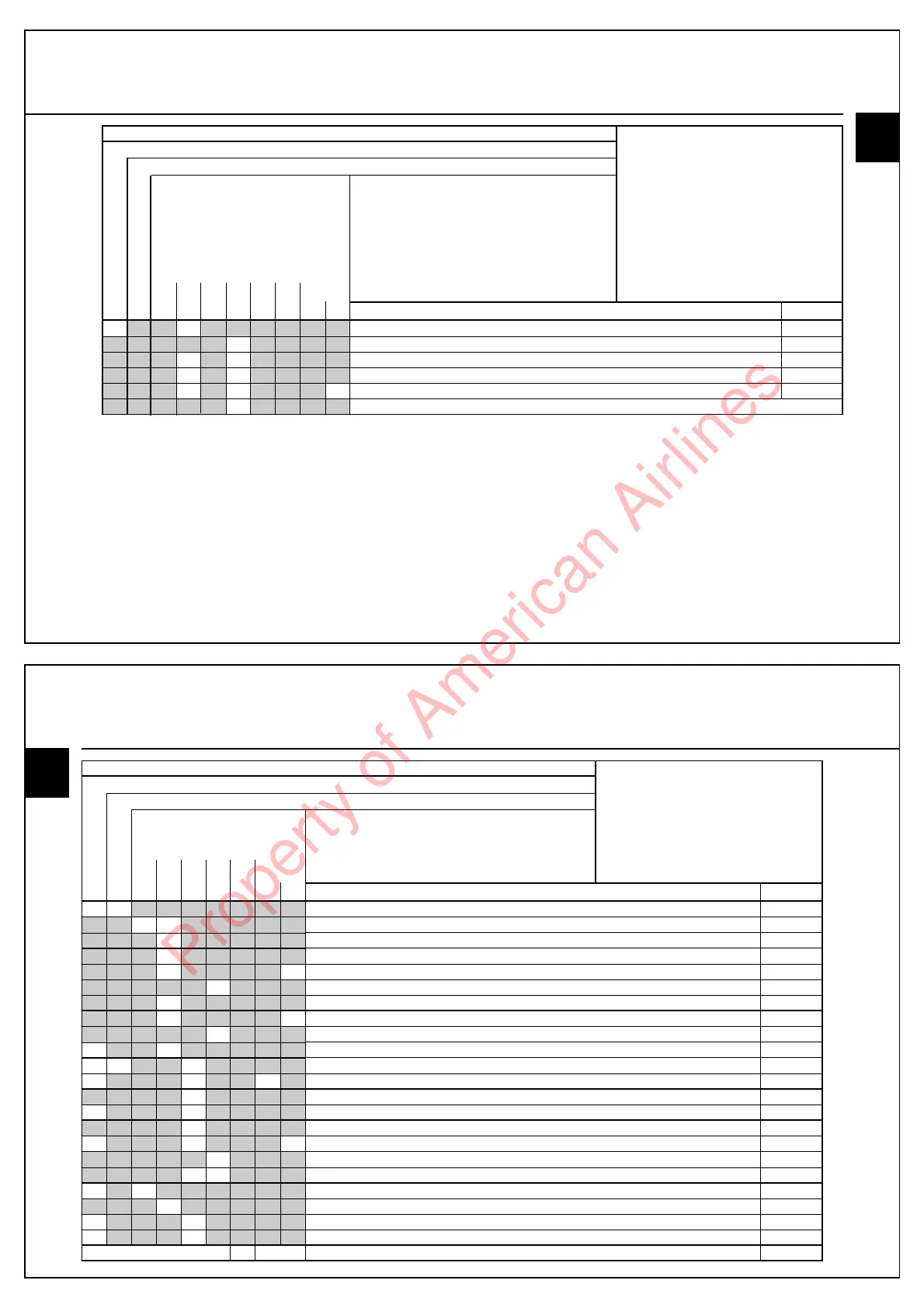

5.1 Maintenance schedule Routine maintenance

check 2x daily before or during 1st trial run, during running- In period or when commissioning new or overhauled engines

every 10 OH or daily

in operating hours (OH) every:

Additions and

modifications for engines

with EPA approval

The specified engine maintenance values are

permissible recommended maximums. Depending

on usage, reduced maintenance intervals may be

necessary; comply with the unit manufacturer’s

operating instructions. # Maintenance must only be

carried out by authorised service personnel.

check = O adjust = clean =

V

replace =

250

500

1000

4000

6000

12000

1

2

Lube oil (oil change int. depending on engine app.), see TR 0199-99-3002 6.1.1/6.1.2

Injection valve #

Intercooler (drain lube oil/condensation) #

Intercooler inlet, clean as necessary –

Crankcase pressure vent valve #

Exhaust Turbo-Charger outlet, clean as necessary –

Years

Operation Section

V

V

V

E10 E20 E30 E40 E70

5

© 2000

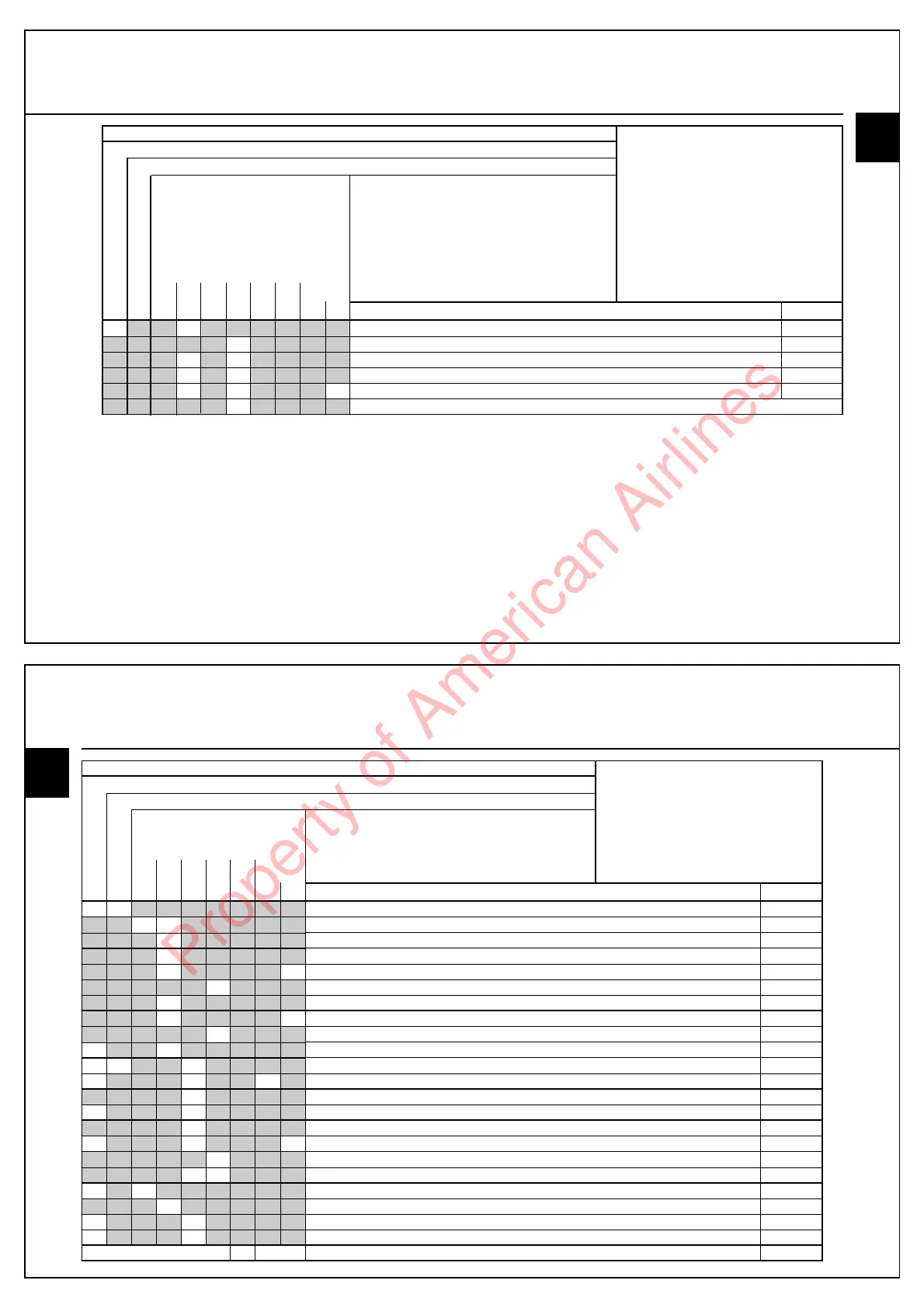

Routine maintenance 5.1 Maintenance schedule

check 2x daily before or during 1st trial run, during running- In period or when commissioning new or overhauled engines

every 200 km or daily

Kilometrage (km) every:

Service group I

Vehicle engines

The specified engine maintenance values are

permissible recommended maximums. Depending

on usage, reduced maintenance intervals may be

necessary; comply with the unit manufacturer’s

operating instructions. # Maintenance must only be

carried out by authorised service personnel.

check = adjust = clean =

V

replace =

5000

10 000

20 000

120 000

240 000

1

2

Lube oil level, top up if necessary 6.1.2/3.3.4

Lube oil (oil change int. depending on engine app.), see TR 0199-99-3002 6.1.1/6.1.2

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Fuel leakage lines (should be replaced in there entirety) 6.2.2

Injection valve #

Fuel pre-cleaner 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant pump –

Coolant level 4.3.2/4.3.3

Intake air cleaner (if available, maintain according to maintenance indicator) 6.4.3/6.4.4

Intercooler (drain lube oil/condensation) #

Battery and cable connectors 6.7.1

Engine monotoring system 3.3

Valve clearance (adjust if necessary) 6.6.1

V-belts (retension if necessary, replaced if damaged) 6.5.1

Crankcase pressure-relief valve/injection valve #

Crankcase pressure vent valve #

Check engine for leaks (visual inspection) –

Draining bores between cylinder banks, engine cleaning 6.3.1/6.3.4

Engine mount (replaced if damaged) 9.2

Fasteners, hose connections/clips –

General overhaul #

Years

Operation Section

V

V

V

Service groupe Annual kilometrage average speed approx.

(km) approx. km/h

I < 30 000 20

II > 30 bis 100 000 40

III > 100 000 60

E10 E20 E30 E30 E40 E60 E70

Property of American Airlines

Loading...

Loading...