6

26 407 0

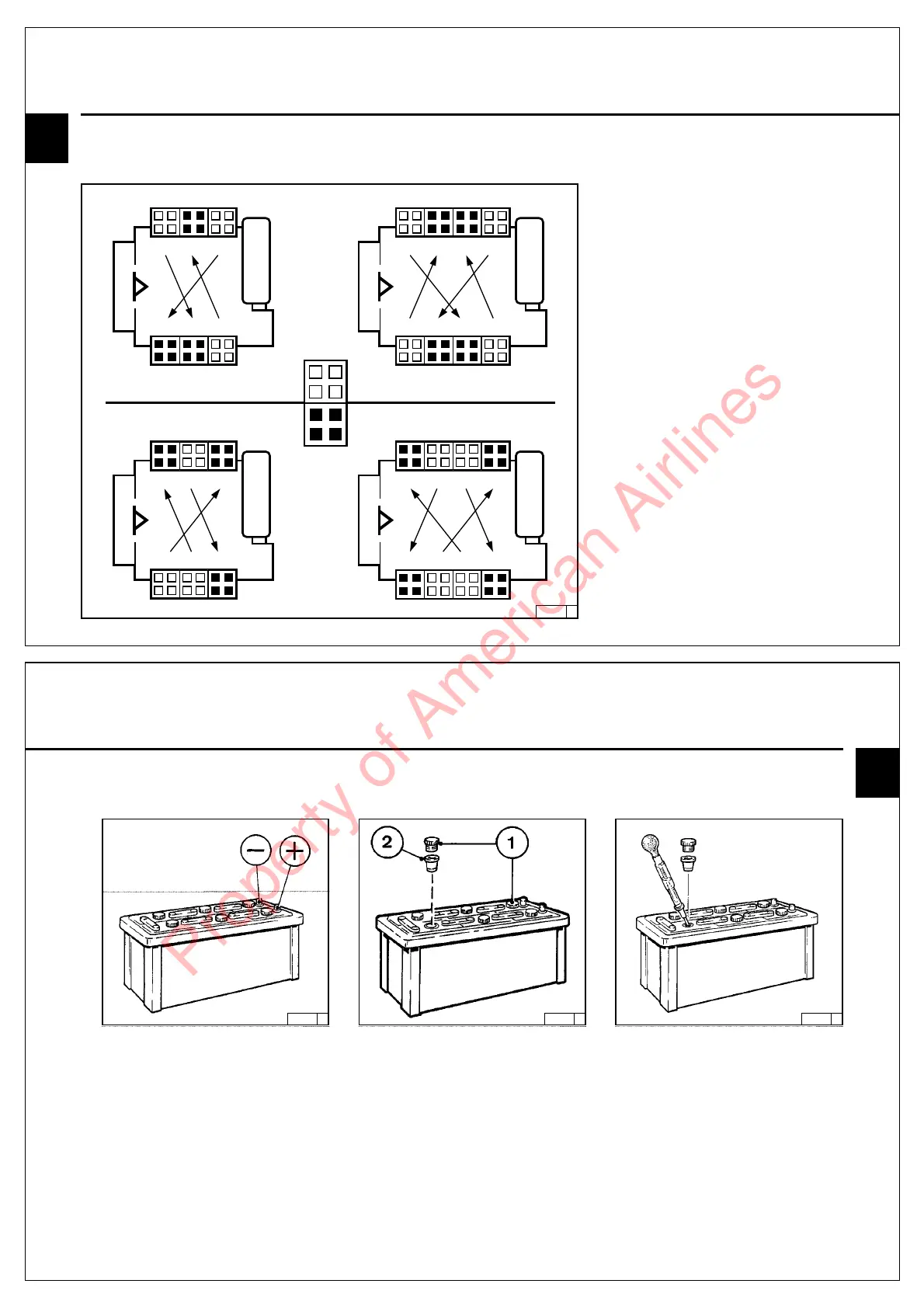

A1 A2 A3

B1 B2 B3

A1 A2 A3

B1 B2 B3

A1 A2 A3

B1 B2 B3

A4

B4

A1 A2 A3

B1 B2 B3

A4

B4

● Adjustment

Turn crankshaft according to sequence shown

in the diagram (starting with cyl. 1).

The valves of the relevant cylinder overlap,

marked in white, (exhaust valves about to

close, inlet valves about to open). Adjust

clearance of valves, marked in black,

according to schematic. Mark the respective

rocker arm with chalk to show that the

adjustment has been done.

Service and Maintenance 6.6 Adjustments

6

25895 0 24232 3 25896 0

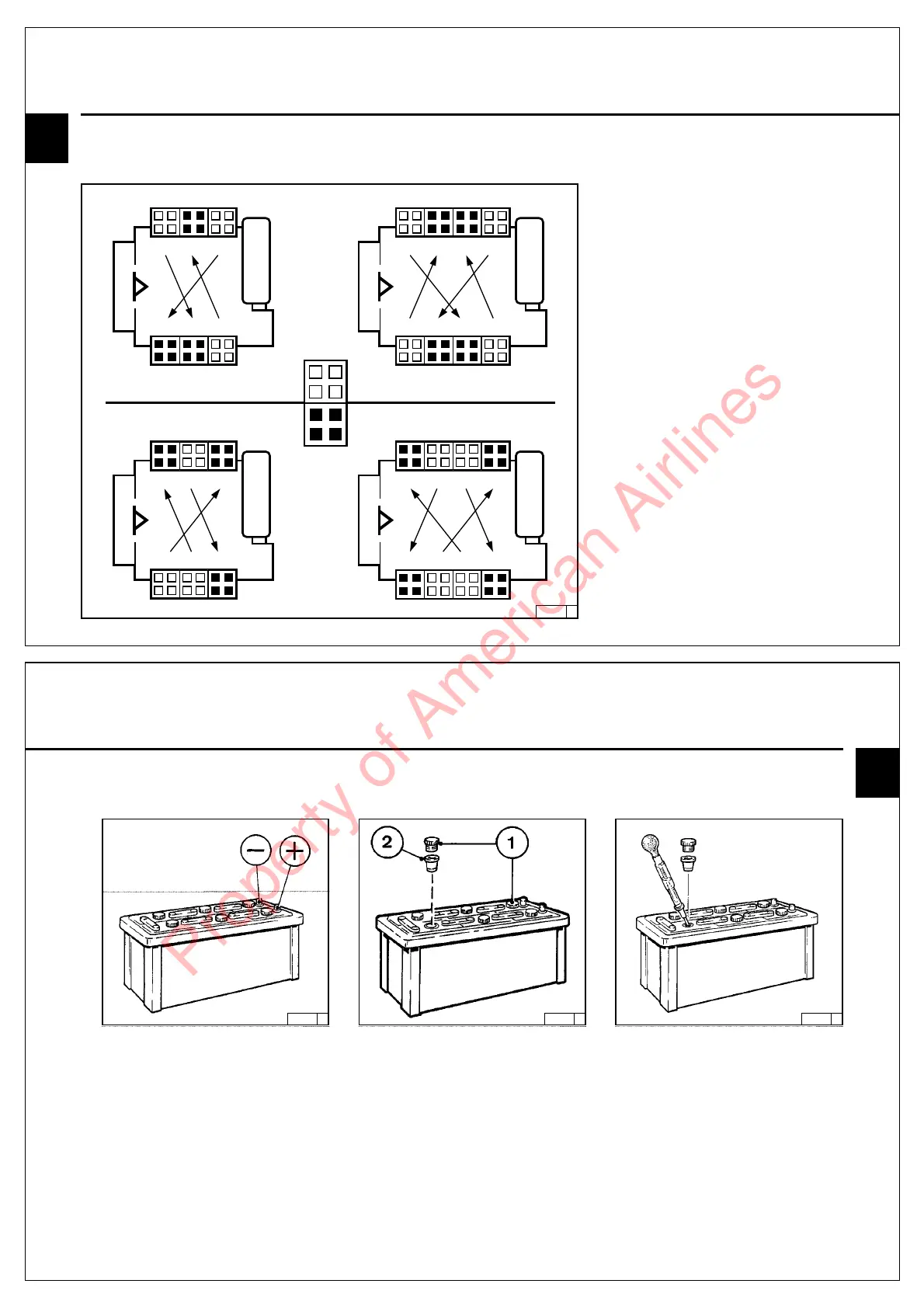

6.7.1 Battery

6.7.1.1 Checking Battery and Cable

Connections

6.7.1.2 Checking Electrolyte Level 6.7.1.3 Checking Specific Gravity of

Electrolyte

● Keep battery clean and dry.

● Undo soiled terminals.

● Clean battery plus and minus poles and

terminals and apply a film of acid-free and acid-

resistant grease.

● When reconnecting, ensure good contact of

terminals. Fasten clamping bolts finger tight.

● Remove cell caps 1.

● If electrolyte test elements 2 are fitted:

The level should be high enough to wet the

bottom of these.

● If no such elements are provided :

Check to make sure that the level is 10-15 mm

above the top edge of the plates.

● Top up with distilled water if necessary.

● Fit cell caps back in position.

● Measure the specific gravity of the individual

cells with a commercial hydrometer.

The measured values (see adjacent table)

indicate the state of charge of the battery.

During the measurement, the temperature of

the electrolyte should preferably read 20 °C.

6.7 Accessories Service and Maintenance

Property of American Airlines

Loading...

Loading...