8

Engine Preservation

8.1 Preservation

26 408 0

12

3

4

If the engine is to be shut down for an extended

period, it is necessary to take preservation

measures to prevent rust formation. The

preservation measures described here will protect

the engine for a period of up to about 6 months.

Before reusing the engine, the preservatives must

be removed,.

● Anti-corrosion oils to Specification:

– MIL-L 21260B

– TL 9150-037/2

– Nato Code C 640 / 642

● Recommended cleansing agent for removing

preservatives:

– Petroleum benzine (hazardous materials

class A3)

Preserving the Engine:

● Clean engine (in case of need with cold

cleansing agent).

Clean cooling system according to

manufacturer’s instructions.

● Run engine until warm and stop.

● Drain engine oil, see 6.1.2, and fill in anti-

corrosion oil.

● Drain coolant, see 6.3.3.

● Fill in anti-corrosion agent, see 4.3.3.

● Clean oil bath air cleaner, if provided, see 6.4.3,

and fill in anti-corrosion oil.

● Drain fuel from tank.

● Prepare a mixture of 90% diesel fuel and 10%

anti-corrosion oil and fill up tank.

● Run engine for about 10 minutes.

● Stop engine.

● Turn engine several times by hand.

When turning engine with starter, move

shutdown lever to stop position.

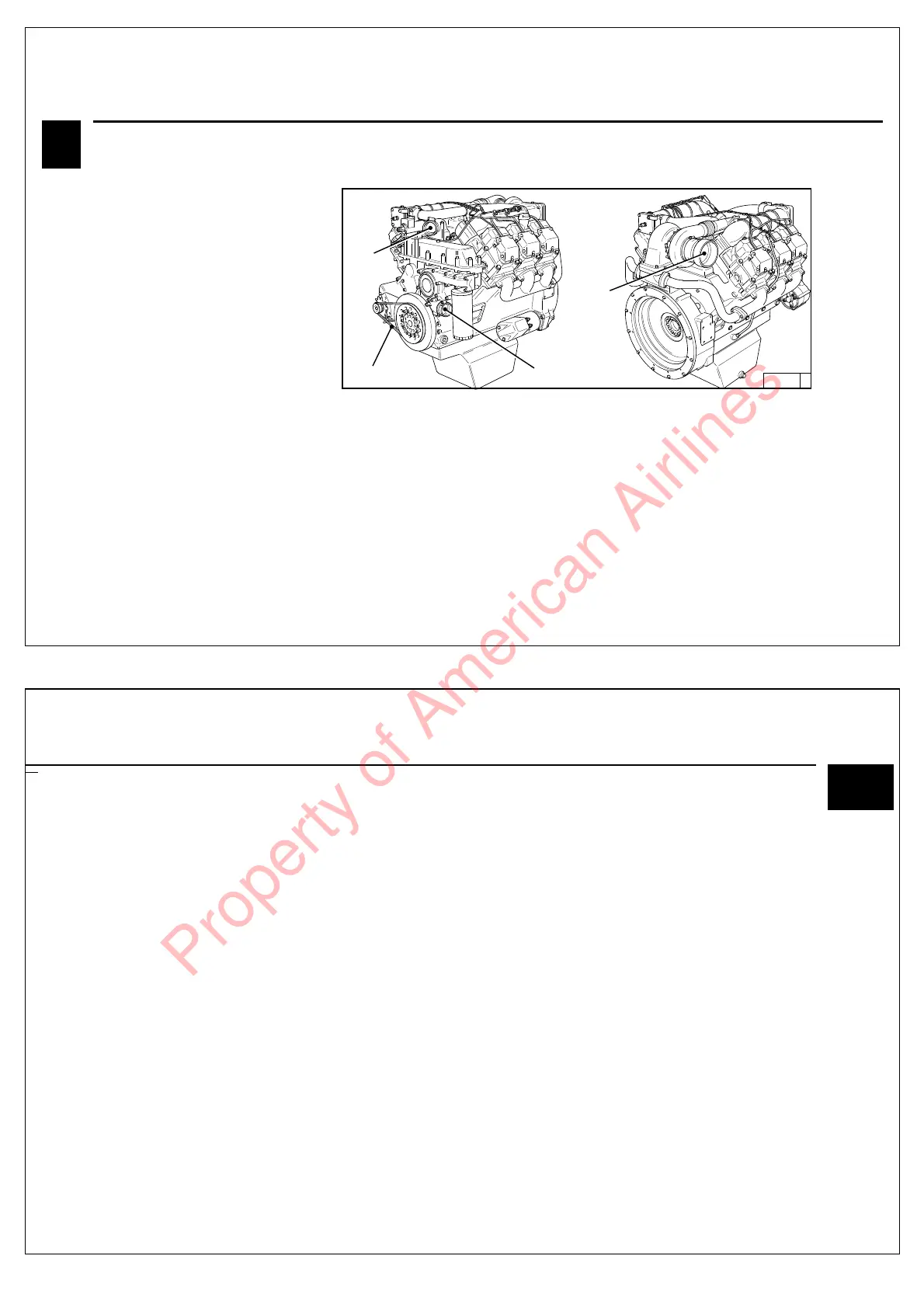

● Remove V-belt 2 and store in wrapped

condition.

● Spray grooves of V-belt pulleys with anti-

corrosion agent.

● Close coolant inlet and outlet openings 3 and

air intake opening 4.

● Close exhaust discharge opening.

8.1 Preservation

● Drain off anti-corrosion agent, see 6.3.3.

Removing Engine Preservatives:

● Remove anti-corrosion agent from the grooves

of the V-belt pulleys.

● Fit V-belt 2. Retension, if necessary, after short

period of operation, see 6.5.

● Remove plugs 1, 3 and 4 and plug from

exhaust discharge opening.

● Fill in coolant according to instructions of

radiator manufacturer.

● Start up engine.

9

Specification Data

9.1 Engine Specifications and Settings

9.2 Torque Wrench Settings

9.3 Tools

Property of American Airlines

Loading...

Loading...