6

33 545 0

6.3.3 Filling / Bleeding Cooling

System

6.3.2 Draining Cooling System6.3.1 Cleaning Intervals

● The degree of soiling of the cooler units is

dependent on the type of engine application.

● The danger of soiling is increased due to

residues of oil and fuel on the engine. Check

extra carefully, therefore, for leakages when

applications involve high dust fallout.

● More severe soiling can occur, e.g. in the case

of:

– Construction site application due to heavily

dust-laden air.

● In view of the varying conditions of application,

the cleaning intervals must be determined from

case to case. The cleaning intervals stated in

the table can be taken as guide values.

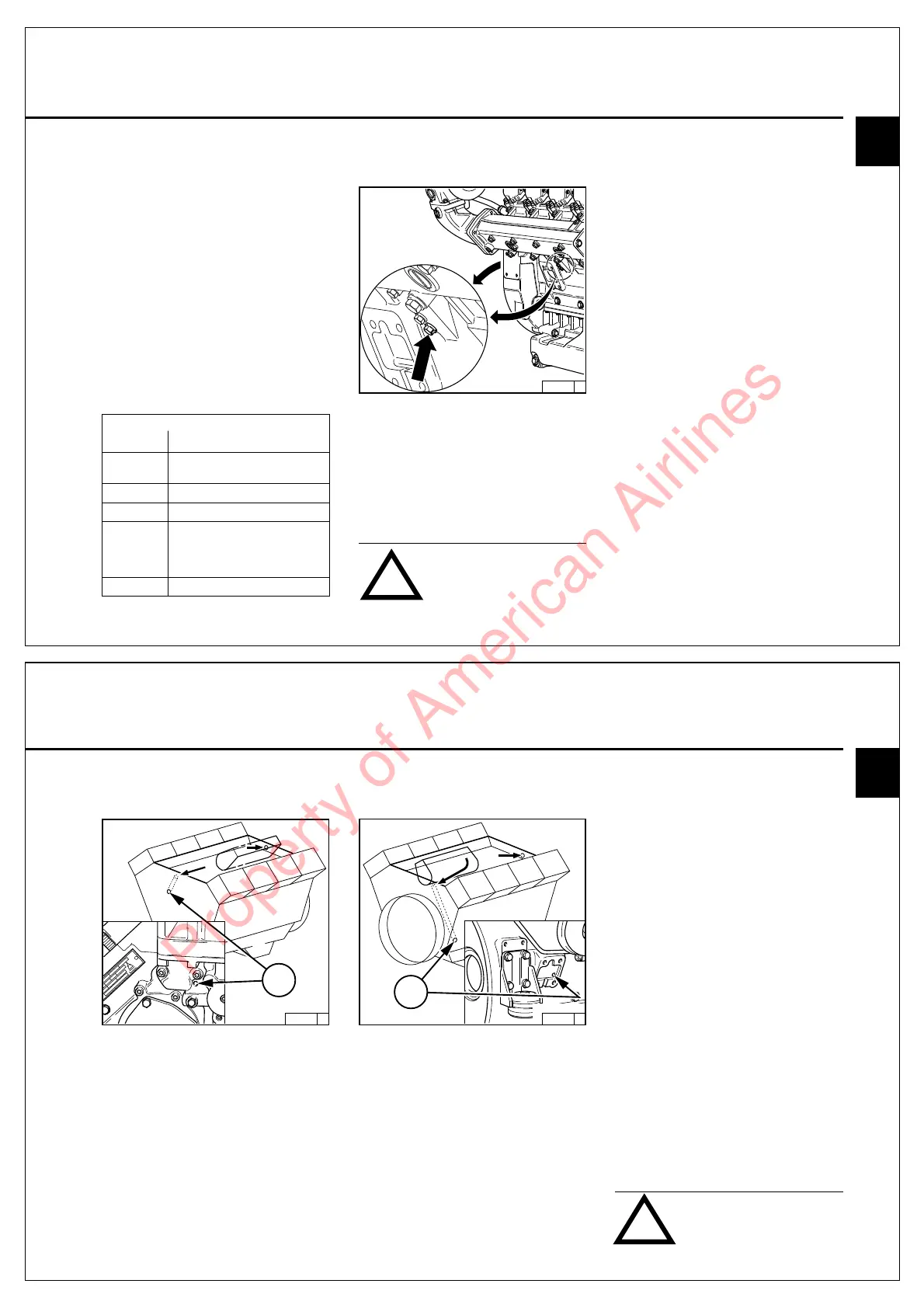

● Place tray under drain plug 1.

● Remove drain plug 1 and sealing ring below

coolant inlet.

● Drain coolant.

● Filling / bleeding as under 6.3.3

● Screw on drain plug 1 with new sealing ring

and tighten (see 9.2).

● Check for leaks.

● Fill with coolant and bleed cooling system

according to manufacturer’s instructions.

Checking / Cleaning Intervals

Engine Application

2000 Ships, gensets in enclosed

spaces, pumps

1000 Vehicles on paved roads

500 Mobile gensets

250

Vehicles on construction sites and

unpaved roads, Construction

equipment, compressors, under-

ground mining equipment

125 Farm equipment

Guide Values

(RH)

6.3 Cooling System Service and Maintenance

Be careful when draining hot

coolant. Danger of scalding!

Catch drained coolant and dispose

of in accordance with anti-

pollution regulations!

!

6

Clean only with engine stationary

1234

1234

A

B

1

432

1

4321

B

A

1

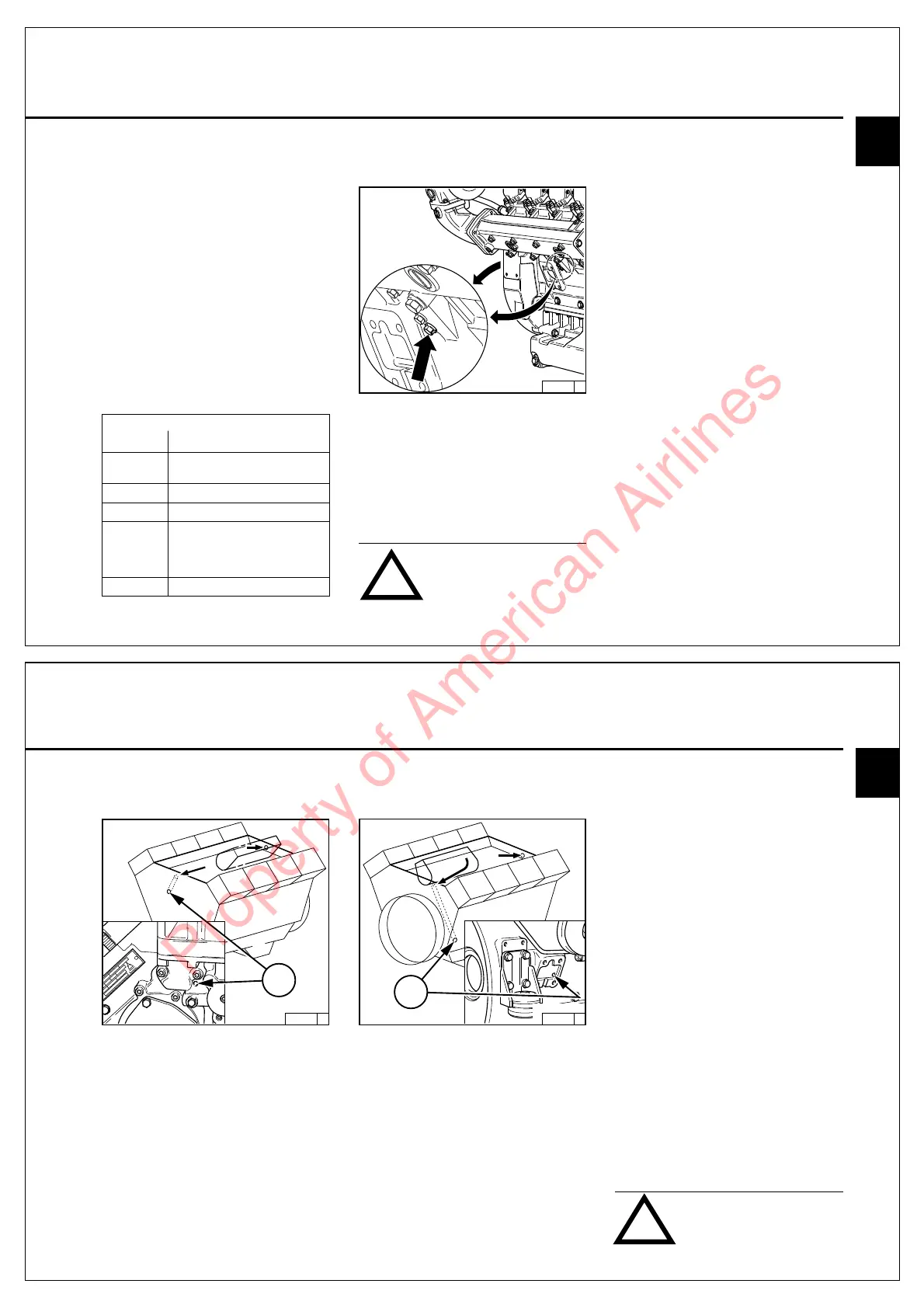

6.3.4 Cleaning engine

- with compressed air

● Blow compressed air onto engine

Wash out loosened dirt particles from V-space

with water jet.

● Make sure that drain holes 1 of V-space are free.

26 454 1 26 455 0

● Let engine run up to operating temperature

after each wet-cleaning procedure allowing

any remaining water to evaporate, thus

avoiding corrosion.

- with cold cleaning agent

● Spray engine with commercial cold cleansing

agent and let stand for about 10 min.

● Then spray clean with strong water jet (do not

spray water directly onto sensitive components

such as alternator, starter, wiring, electronic

components).

● Make sure that drain holes 1 of V-space are free.

!

6.3 Cooling System Service and Maintenance

Property of American Airlines

Loading...

Loading...