HI, MI, WI-700 service manual - 2 - component parts

2-19 Issue 9 04/2020

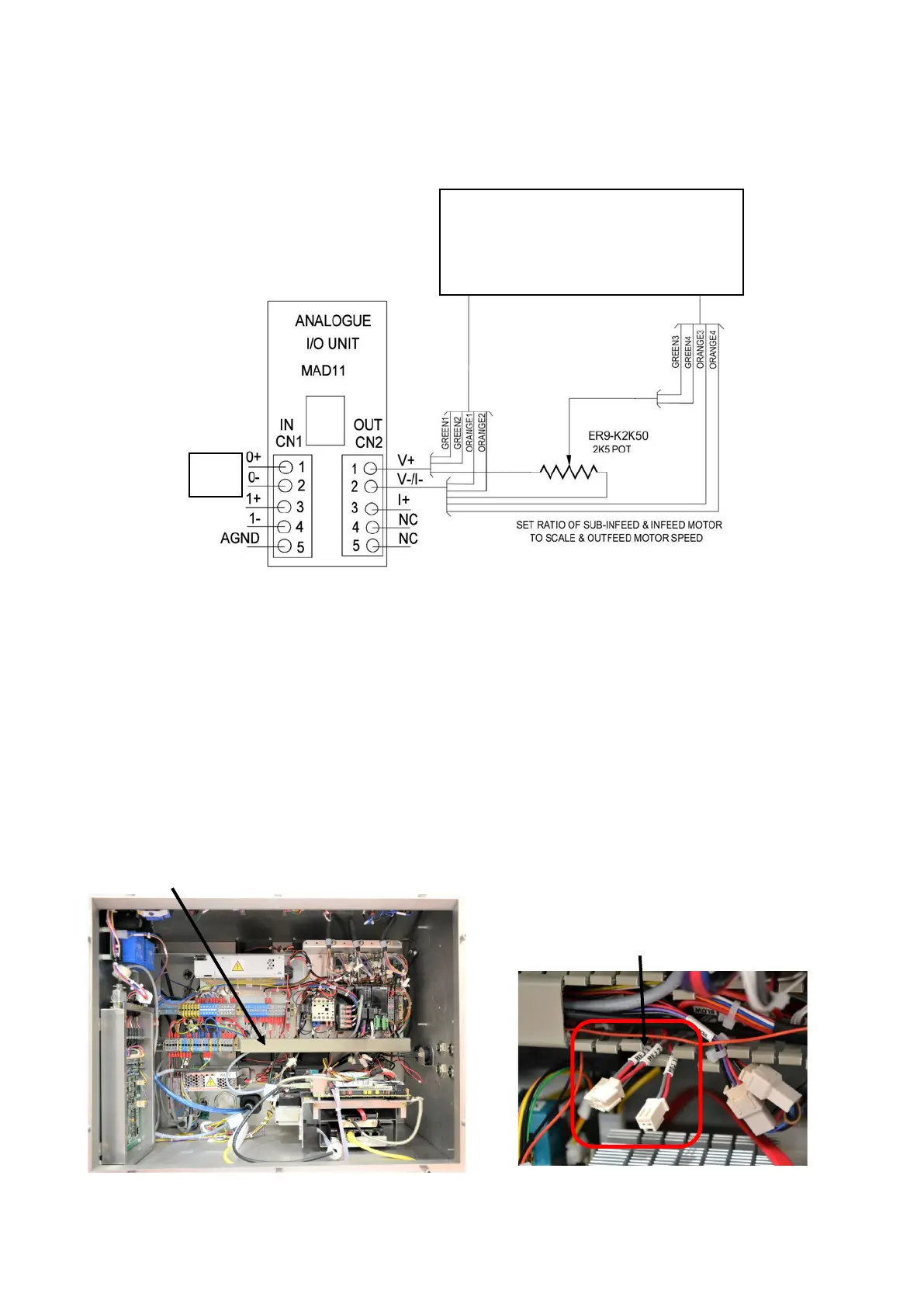

MAD11 analogue unit

Refer to the electrical drawings for more details on the connection to and from this unit.

To Motor speed control boards

Green to VRM

Orange to VRL

Note: infeed output goes through a

2K5Poteneometer for separate speed adjustment

Not

used

The final speed of the conveyors is controlled by the output voltage from CN2; therefore this voltage is

variable depending on the conveyor speed selected.

The range the voltage will be is between 1v and 5v (1v being slowest speed, 5v being max speed)

This voltage is connected to each motor speed control board at VRM (green) and VRL (orange).

The 2K5POT is used to adjust the sub-infeed & infeed to a slower speed that the set conveyor ppm. This is

useful to extend a larger gap between packs at the infeed stage.

Note: if a sub-infeed is fitted they may be an independent pot for each infeed.

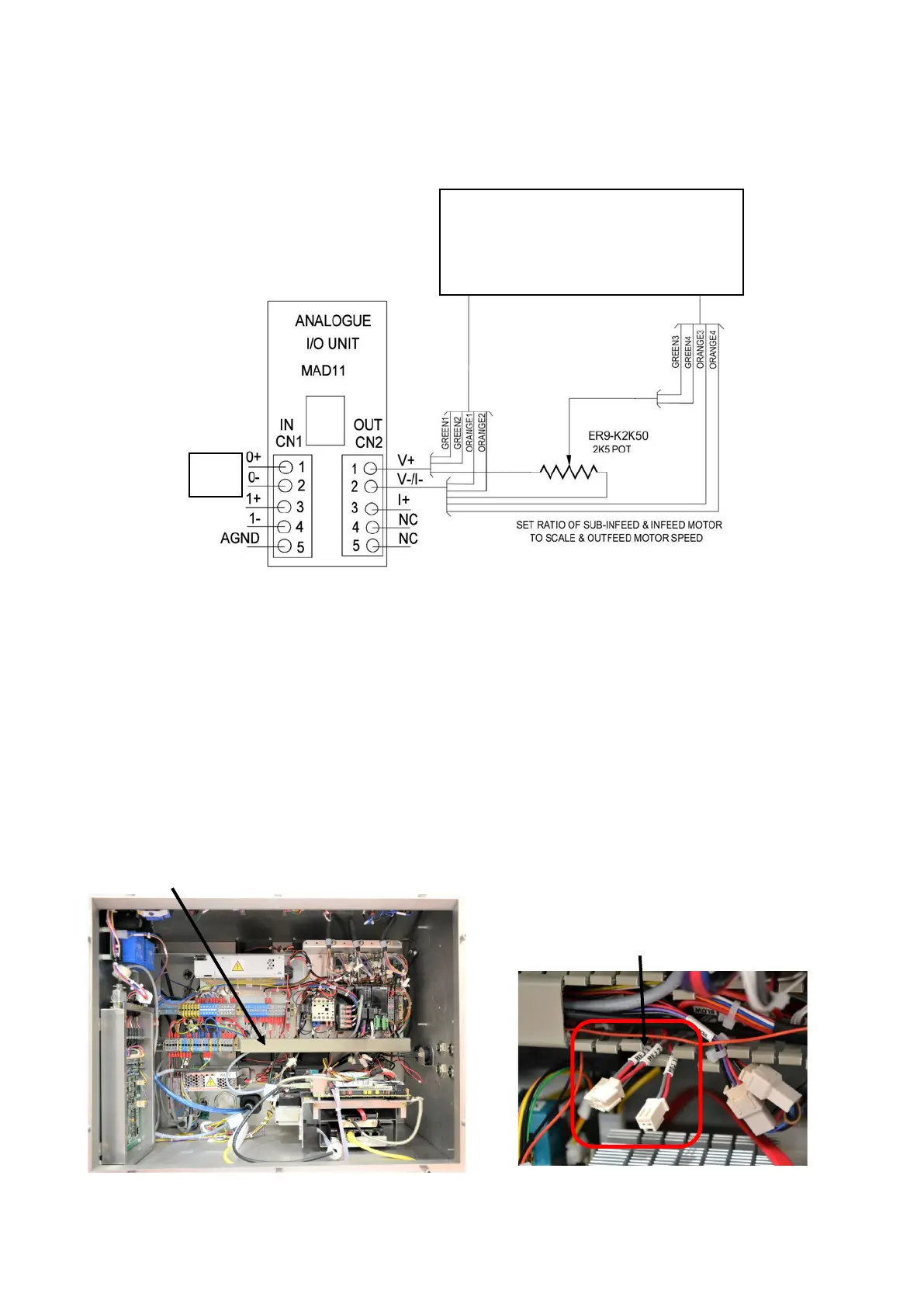

Rejector signal output

If a rejector is to be connected to the HI there are three outputs from the PLC each having a 2 way Molex

connector fitted. The connectors are marked as REJ 1, REJ 2 & REJ 3.

Remove or slide left this trunking cover

REJ 1, REJ 2 & REJ 3 are

located here

Loading...

Loading...