22

When draining the tank, ensure that

there is a large enough air inlet at

the top to avoid any depression in the

tank; failure to do so will invalidate

the warranty.

Maintenance

8 Maintenance

The maintenance of this appliance covers the critical ar-

eas of the Domestic Hot Water Cylinder, the Heat Pump

Module, Air Connections and Electrical Connections.

8.1 DHW Cylinder

After servicing, complete the relevant Service Record

section of the Benchmark Checklist located on the inside

back pages of this document. To meet with warranty re-

quirements, the cylinder must be serviced annually.

Periodically the immersion heater should be removed

drained for internal inspection Check the O-ring seal for

damage and replace if necessary. A torque of 40 Nm is

recommended when tightening up the immersion after it

1. Draw some water from cold water tap and retain

in container.

2. Isolate cold water mains supply from cylinder.

to assure safe discharge and check that valve is

not dripping when closed.

safe discharge and check that valve is not dripping

when closed. The expansion relief valve should be

operated regularly to remove lime deposits and to

verify that it is not blocked.

5. Open hot water tap and release remaining pres-

sure from unit.

6. If the system is drained completely for an inter-

nal inspection, ensure the hot water tap remains

open, connect a hose to the drain valve and en-

sure a safe discharge.

7. Note the set pressure of the pressure reducing

valve. Remove cartridge and clean strainer in wa-

ter provided in container. Re-assemble pressure

reducing valve ensuring the correct pressure is

set.

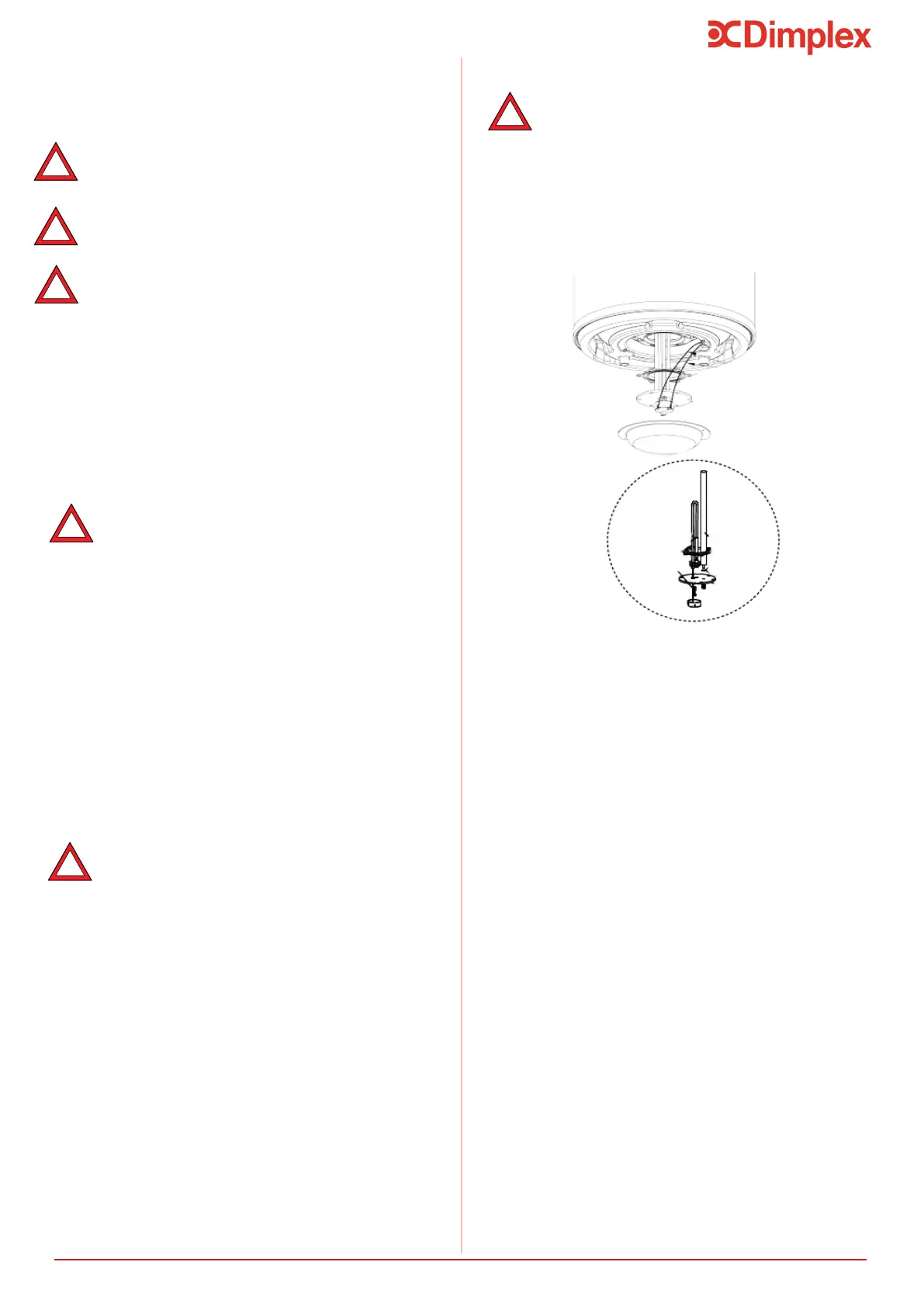

Figure 17:Immersionheatercleaning

-

prove durability it is advised that an an-

nual maintenance check should be car-

•

before opening it.

• Wait for the fan to come to a complete

stop before starting work on the

appliance.

• Do not get any water on any of the

electrical components.

• The pressure-limiting device should

be activated regularly to eliminate

limescale and to check for blockages.

• The R290 refrigerant is odourless.

• Do not damage the pipes in the

refrigerant circuit.

•

appliance.

• If the refrigerant is leaking, unplug the

appliance, air out the room, and contact

customer service.

• Do not use any mechanical means to

speed up the defrosting process.

• Do not pierce or burn the appliance: in

case of intervention on the refrigerant

circuit, the refrigerant must be

recovered.

- In case of maintenance of the refrigerant cir-

cuit:

1) Secure the area you will be working in,

2) Inform people of the potential danger in-

volved in the work.

-

imised.

5) Check the area with an appropriate leak de-

tector before and during the work.

6) Place a CO dry powder extinguisher near

the work area.

The R290 refrigerant in the heat pump

circuit poses no risk to the environ-

-

mable refrigerant complies with all na-

tional gas regulations.

8. Periodically the immersion heater should be re-

system is drained for internal inspection Check

the O-ring seal for damage and replace if neces-

sary. A torque of 40 Nm is recommended when

tightening up the immersion after it has been re-

9. Check electrical wiring connections and the condi-

tion of the cable of the immersion heater and the

thermostat.

10. The immersion heater boss can also be used for

access to view the internal components of the cyl-

inder.

11. Re-commission unit (see chapter 7.1).

Failure to service this appliance annual-

ly may invalidate the warranty.

All maintenance on this product must be

required.

Loading...

Loading...