SK3000 Operator’s Manual Maintenance - 83

Procedures

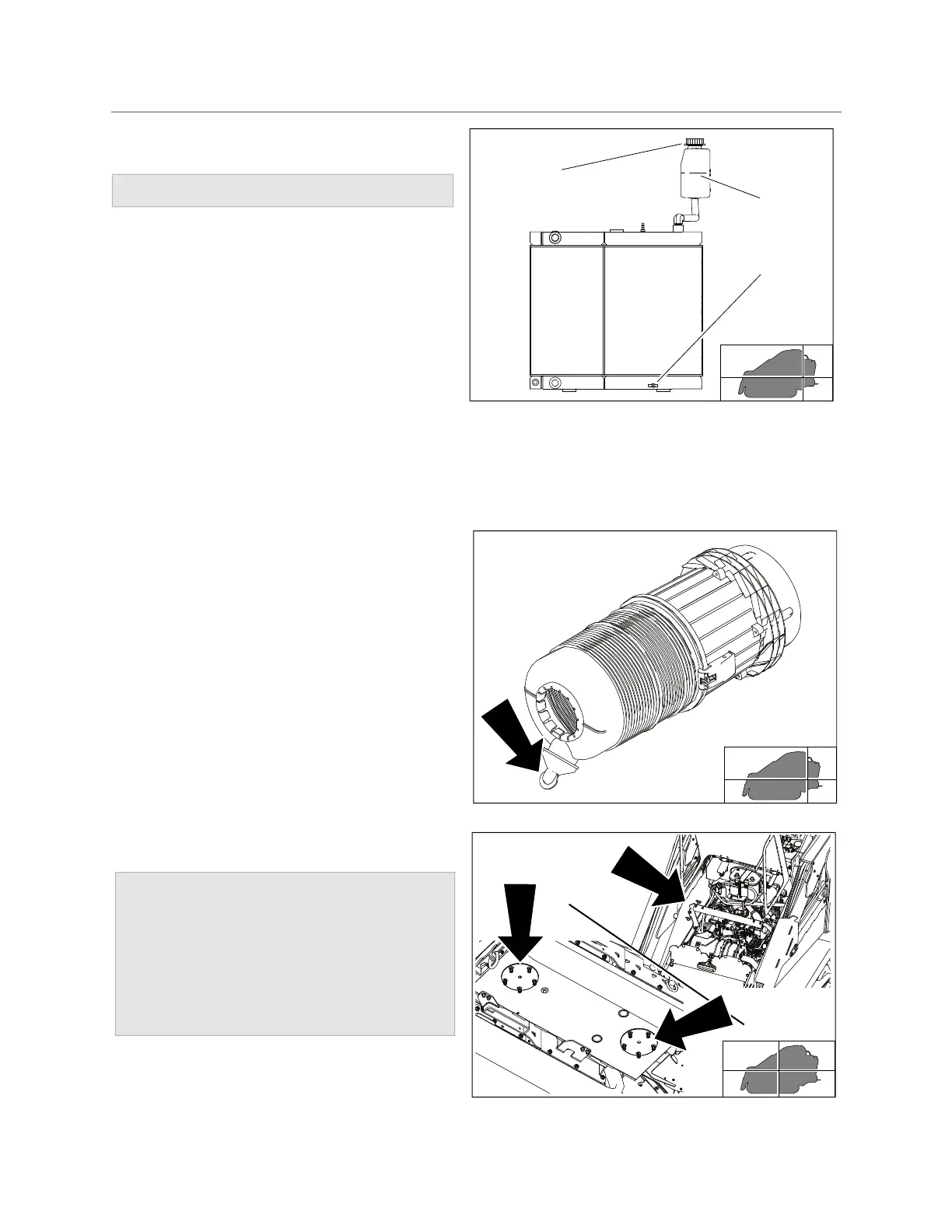

Coolant

Check before startup and every 10 hours. Change

every 1000 hours.

Check Level

1. Check at overflow bottle (2).

2. Add DEAC at fill (1) as needed to keep level at

halfway point on overflow bottle.

Change

1. Remove plug (3) to drain.

2. Install plug.

3. Add DEAC at fill to keep level at halfway point on overflow bottle.

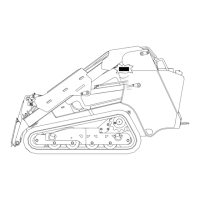

Dust Ejector Valve

Check dust ejector valve (shown) before startup

and every 10 hours. Ensure valve is not inverted,

damaged, plugged, or cracked.

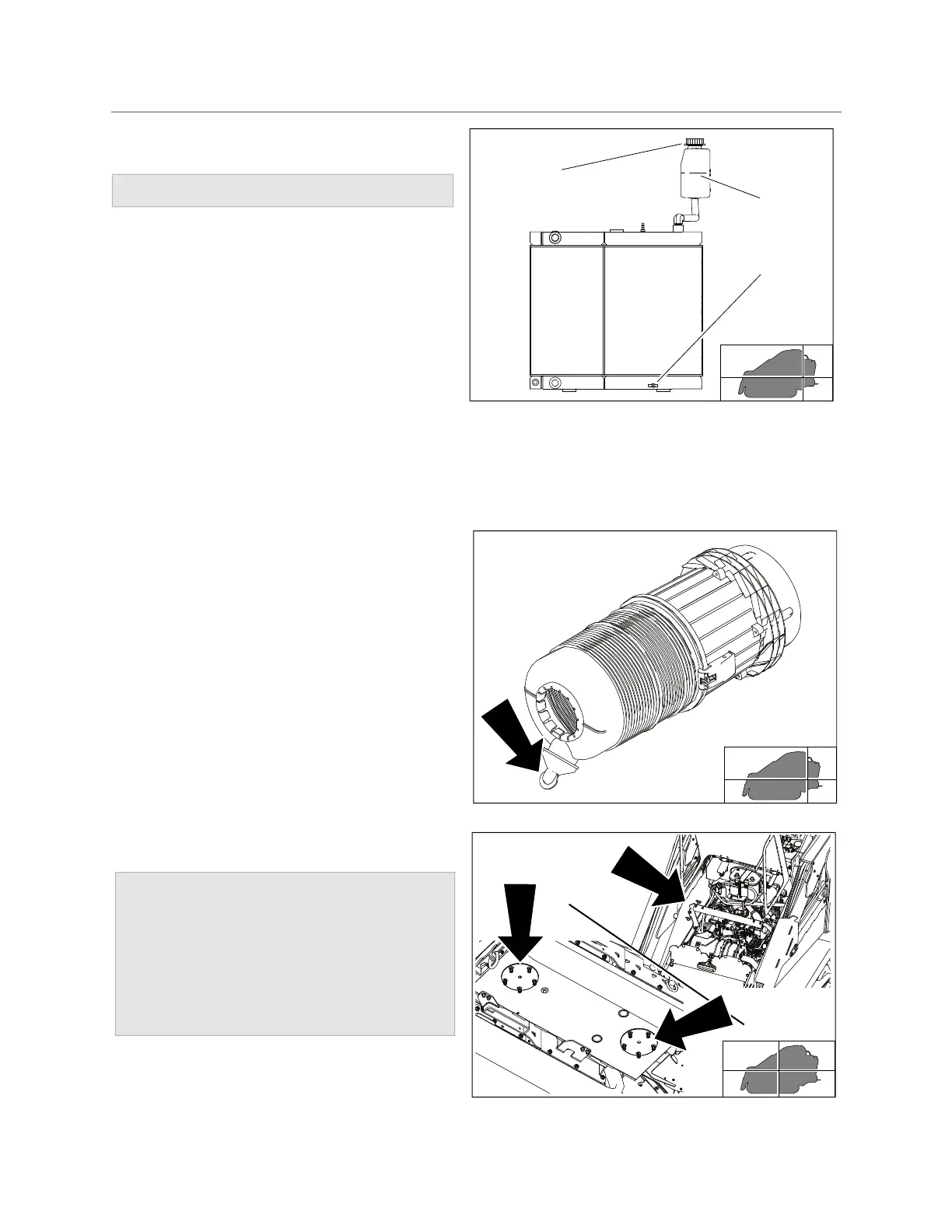

Engine Compartment

Check engine compartment (shown) for debris

every 10 hours and after long-term storage.

Manually clean out debris as needed.

NOTICE: See “Approved Coolant” on page 75.

NOTICE:

• Check more often if operating in large

brush, grassy conditions, or if machine is

being stored.

• Do not use water or compressed air to

remove debris.

1

3

2

t62om035w19.eps

t62om052w19.eps

Loading...

Loading...