SK3000 Operator’s Manual Maintenance - 91

Procedures

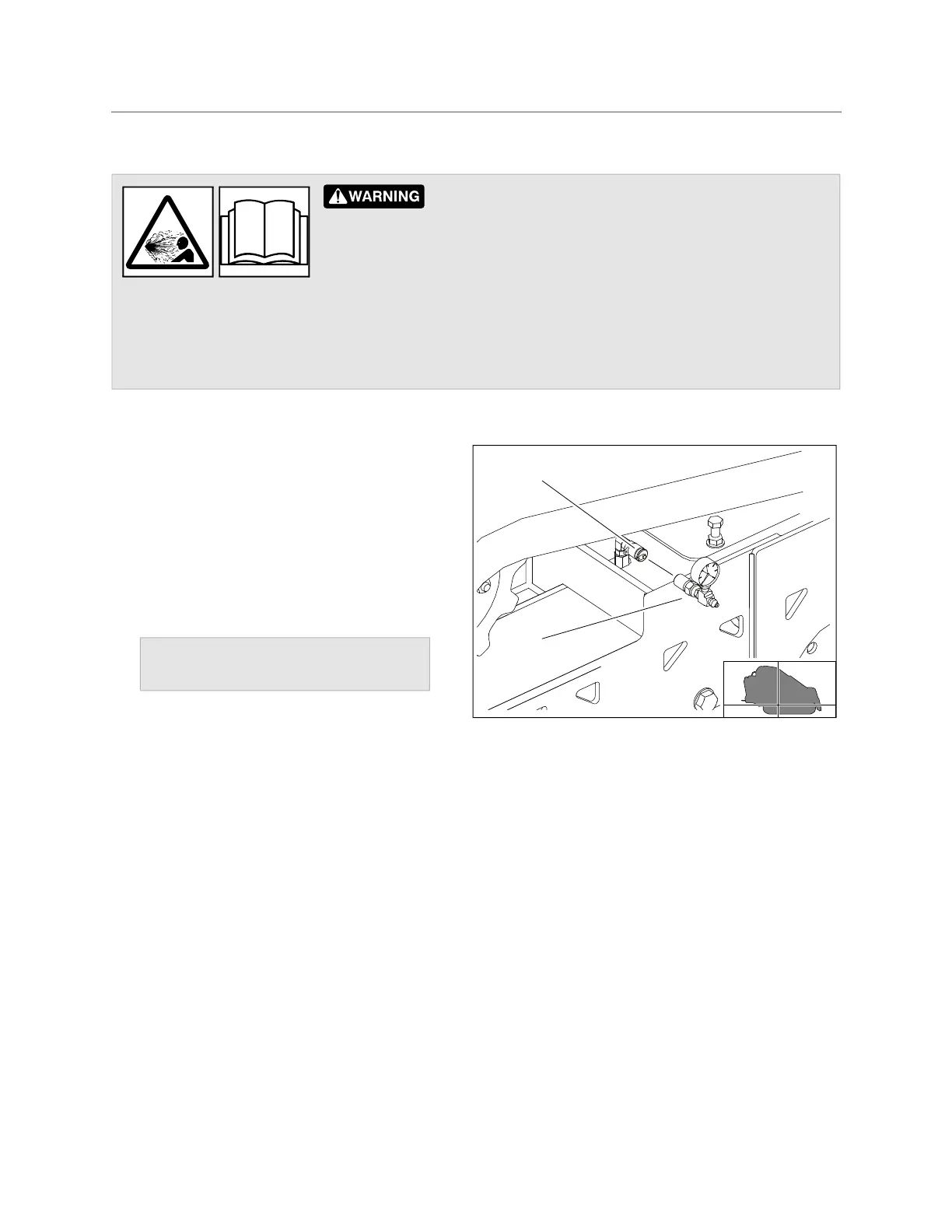

Track Tension

Check before startup and every 10 hours. Adjust as needed.

Check

1. Lift track.

2. Remove gauge (1) from stored location.

3. Thread gauge into connection (2).

4. Track is correctly tensioned when gauge

measures 900psi (62bar) and needle is in

green.

Adjust

1. Lift track.

2. Remove gauge from stored location.

3. Thread gauge into connection.

4. Adjust tension.

• To tighten, pump MPG into grease zerk until gauge measures 900psi (62bar) and needle is in

green.

• To loosen, remove plug and drain all grease. Then follow tightening procedure.

Contents under pressure. Impact can cause death or

serious injury. Relieve pressure before opening.

To help avoid injury:

• Service track grease cylinder only while standing away from zerk.

• Cover connection with heavy cloth when relieving pressure in cylinder.

NOTICE: Checking track tension with

gauge will cause pressure to drop.

1

2

t62om025w19.eps

Loading...

Loading...