IC100C Series PRELIMINARY

1592015000 Manual IC100C Series 28/05/03 Page 12 di 38

26. RELAY CONFIGURATION

Relay n° 1 = Compressor 1

Relay n° 2-3 automatically change their configuration

depending on the unit configuration.

Relay n° 2 = Anti-freeze heater CF01 = 2-3-4-5; integration

heater with CF01 = 0 - 1

Relay n° 3 = Water pump, with CF01 = 2-3-4-5; supply air

fan CF01 = 0 –1

Value of par.CF20

Relay

0 1

°n 4

Inversing

valve

Fan ON/OFF

Value of par.CF21

Relay

0 1 2 3

°n 5 Alarm

Stage of the 1

st

compressor.

2

nd

compre

ssor

Fan

ON/OFF

When working with one compressor with one stage valve:

the relay n°5 is configured as stage valve CF21=1: the

polarity of the stage valve is determined by C010.

CO10 = 0 RL1 comp. RL5 parz.

No call OFF OFF

Compressor call ON OFF

1

st

Stage call ON ON

CO10 = 1 RL1 comp. RL5 parz.

No call OFF ON

Compressor call ON ON

1

st

Stage call ON OFF

27. DATA LOGGER

The data recording is enabled if the log time LG08 > 0.

The recordable data can be included enabling the LG01 to

LG07 parameters.

28. BOILER FUNCTION

The electric heater can be activated as heating integration

control Ar20=0 or heating control Ar20=1 during the heat

pump functioning mode.

It is enabled only if:

• Unit configured in Heat Pump mode CF01=3-5.

• Pb4 configured as external air probe CF07=3.

28.1 Heating Integration Control Ar20=0

The Boiler function starts when the Pb4 probe value

decreases under Ar21 value.

If the water temperature detected by the regulation probe is

lower than the ST03 parameter, the electric resistance

heater is activated. The on/off algorithm of the electric

resistance heater is the same as the compressor control

with Heat Pump mode.

If the external air temperature becomes higher than Ar21 +

Ar22 (differential), the integration function stops working

and the unit restarts (or still work) with Heat Pump mode.

28.2 Heating Control Ar20=1

The Boiler function begins when the Pb4 probe decreases

under Ar21 value. When the delay is expired, if the water

temperature detected by the regulation probe is lower than

the ST03 parameter, the compressors are stopped while

the electric resistance heater is activated. The on/off

algorithm of the electric resistance heater is the same as

the compressor control with Heat Pump mode.

If the external air temperature becomes higher than Ar21 +

Ar22 (differential), the Boiler functions stops working and

the unit restarts with Heat Pump mode, compressors and

fans restart working.

29. MAINTENANCE FUNCTION

CO14 for 1

st

compressor, CO15 for 2

nd

compressor and

CO16 for water pump or supplied air fan (air/air) are the

maximum time running hours to signal a maintenance

request, the icon

is blinking. The icon only indicates

the need of a check: nothing else happens. It stops

blinking just after resetting the hour counter under the

function Menu.

30. BLACK OUT

After a black-out:

1. The controller restarts from the pervious status.

2. The defrost cycle is stopped.

3. All the working time delay will be reloaded.

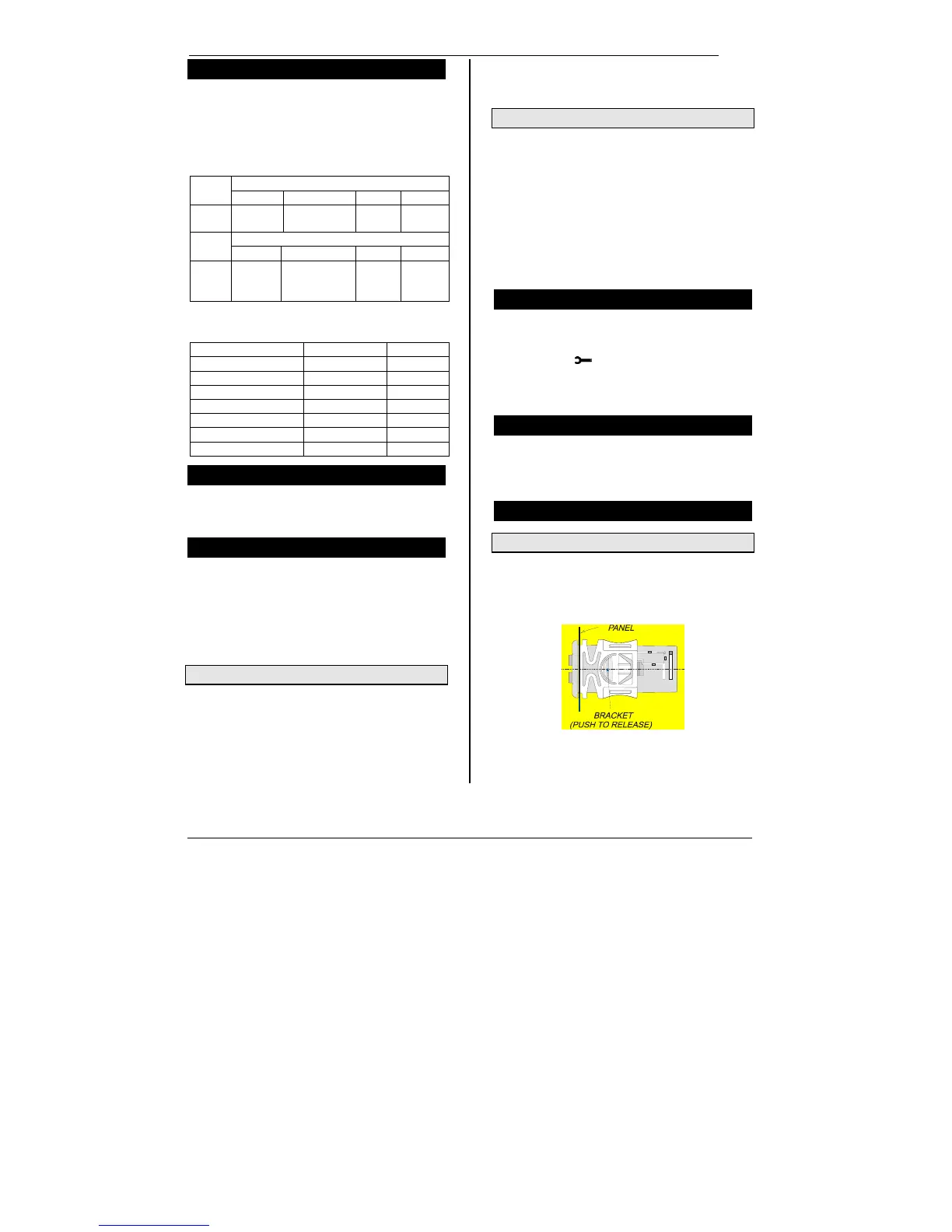

31. INSTALLING AND MOUNTING

31.1 “C” Format (32*74mm)

The instrument shall be mounted on panel, in a 29x71 mm

hole, and fixed using the special bracket supplied.

To obtain an IP65 protection grade use the front panel

rubber gasket (mod. RG-C) as shown in figure 1.

Loading...

Loading...