7

INSTALLATION

All “left”, “right”, “front” and “rear” desig-

nations in this manual are as viewed by the

operator facing the control console.

LOCATION

1. The oor area required by the standard machine

is 105.25 inches (2673.4 mm) in width by 60.18

inches (1528.6 mm) in length. Machine height is

78.81 inches (2001.8 mm). Refer to pages 1, 2

and 3 for further machine dimensions.

2. The machine’s nal location should also provide

the following:

• Sufcient space for easy stock loading and re-

moval.

• Adequate clearance for necessary door openings,

lubrication, maintenance and repair procedures,

including optional chip conveyor removal.

3. Accessories such as conveyors or material handling

equipment will require additional work area.

OSHA NOTICE!!

OSHA Regulation 1910.212 (5B).

Machinesdesignedforaxedlocationshall

be securely anchored to prevent walking or

moving.

UNPACKING

1. The machine is fastened to and shipped on a wooden

skid. Overseas shipments are also crated.

2. Place the machine in its nal position and remove

all protective covers, strapping, crating, etc. Then:

(a) DO NOT remove the bracket which fasten the

saw head to the saw frame; (b) Remove all bolts

which fasten the machine to the shipping skid; (c)

Check around the machine for boxes and/or other

extra machine parts which may have been placed

there for shipment; (d) Inspect the machine and all

parts for shipping damage. Claim procedures are

listed on this manual’s inside front cover.

LIFTING

NEVER lift the machine by its sawing head.

1. Four (4) permanent lifting lugs are provided for

machine lifting purposes and are located in each

corner of the machine base.

2. Using chains attached to the lifting lugs, it is recom-

mended that lifting and transporting the machine be

done with an overhead hoist. It may be necessary to

protect the saw's surfaces from damage where the

chains come in contact with such areas. Net weight

is approximately 3800 pounds (1723.7 kg).

3. Conveyors or material handling equipment can be

lifted and transported by overhead hoist, fork lift,

or by other means that provides adequate safety

precautions.

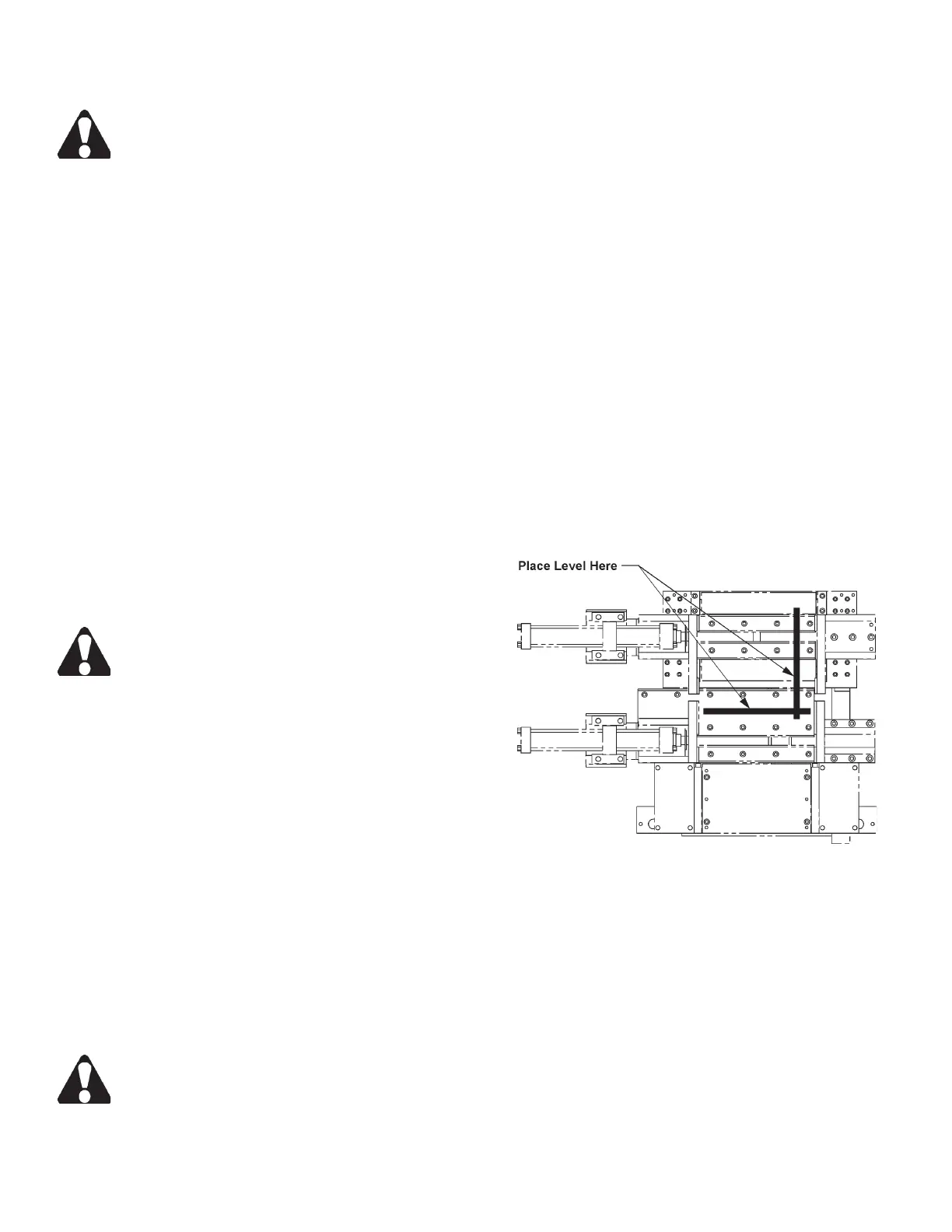

FLOOR INSTALLATION

1. Thread the seven (7) provided leveling screws

(M20 x 2.0) into the machine base mounting holes

and attach the jam nuts. Position the foot castings

under the leveling screws.

2. Place a machinist’s level on the outboard vise bed

and inboard rollers of the index vise. Adjust the

leveling screws until the machine is level and weight

bears evenly on all mounting pads.

Leveling the Machine.

3. The following are important dimensions to be ob-

tained during leveling:

• The roller and vise bed bearing surfaces are to be

co-planar within 0.015 inch (0.38 mm).

4. After the machine has been leveled, install anchor-

ing screws through the base pad holes next to the

leveling screws.

5. Remove the protective shipping bracket installed

to connect the saw head to the base frame during

shipping.

Loading...

Loading...