20

COOLANT SELECTION AND APPLICATION

Coolant Selection

1. Excessive heat build-up is the main cause of blade

tooth failure during band machining. Coolant

has both lubricating and cooling properties. Its

application does the following: (a) Helps reduce

the heat generated during sawing; (b) Helps prolong

blade life; (c) Generally promotes more efcient

cutting rates.

2. When making a coolant choice, the operator will

want to consider the following points: (a) The type of

material being cut; (b) The material's machinability

rating; (c) Band speed and feed rate to be used;

(d) Saw band type to be used and its expected life;

(e) The overall sawing operation.

3. Using more than one (1) coolant variety may provide

maximum sawing results and economy.

Information describing the different types of

coolant and their applications are available

from a DoALL Industrial supply Center rep-

resentative.

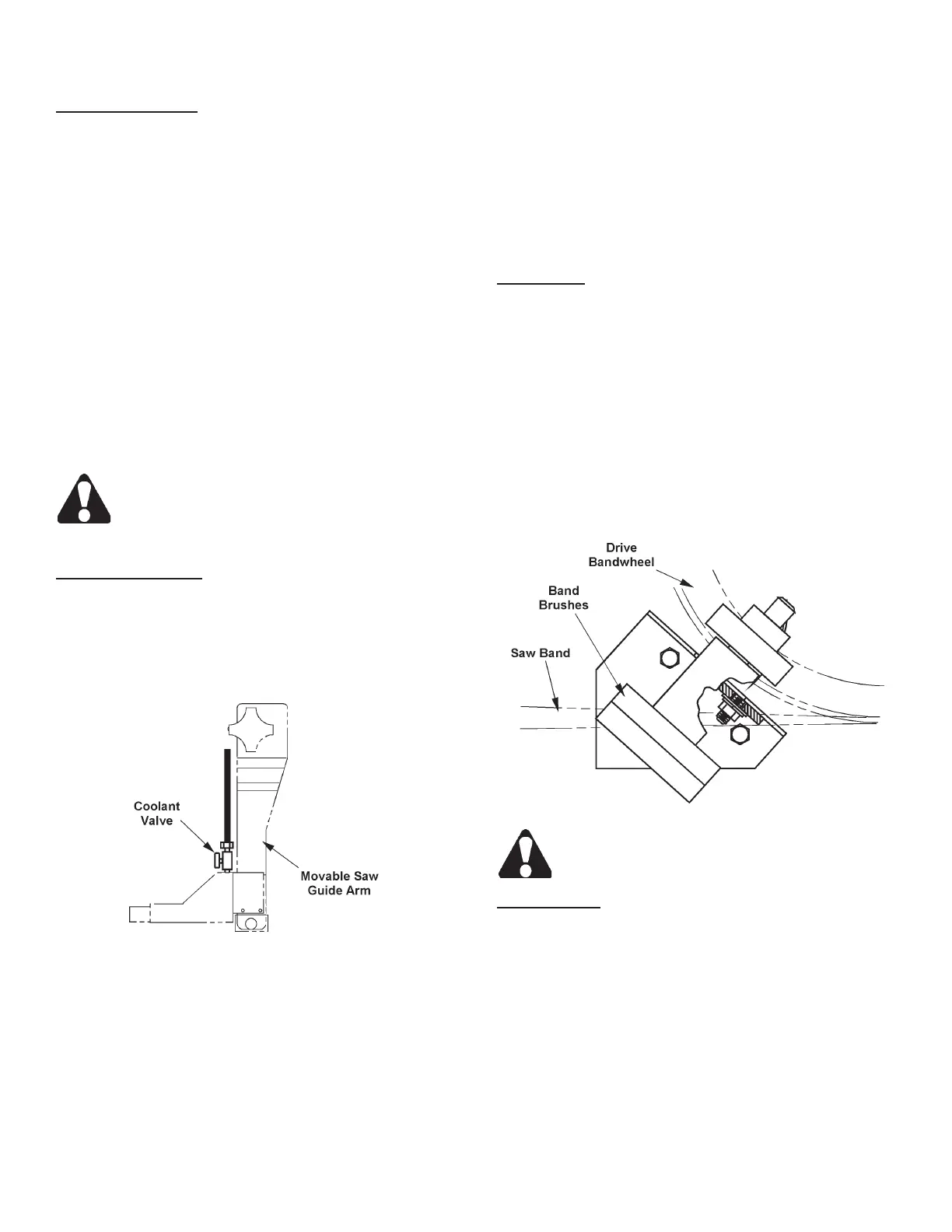

Coolant Application

1. Coolant is supplied by means of a reservoir and

pump to the cutting area through the saw guide

inserts on the movable saw guide arm. Turn the

valve counterclockwise until coolant completely

covers both sides of the saw band.

Coolant Valve on the Saw Guide Arm.

2. The ushing hose attaches to the coolant pump

and delivers cutting uid through a hand nozzle. It

is used primarily for machine cleaning purposes.

3. Used coolant ows back to the reservoir through

the opening in the coolant trough. Coolant reservoir

capacity is 19 gallons (71.9 liters). The pump

will not operate correctly unless it is completely

submerged in coolant.

DRY CUTTING

1. The operator may nd it desirable to cut some mate-

rials (such as cast iron, aluminum, magnesium, etc.)

without coolant. When dry cutting these materials,

follow the same operating procedures used when

cutting with coolant. However, dry cutting will

reduce saw band life.

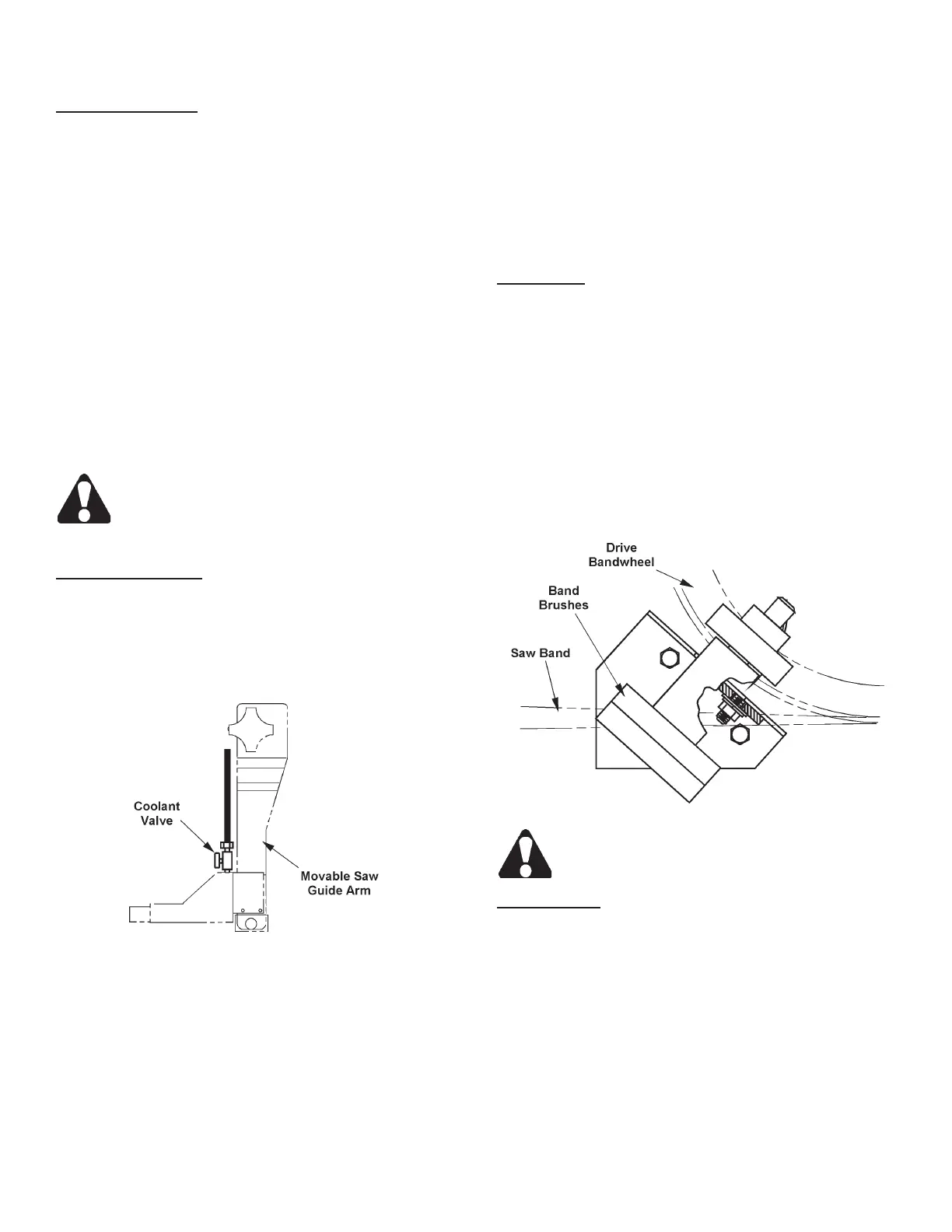

BAND BRUSH AND CHIP REMOVAL

Band Brush

1. A powered band brush removes metal particles from

the saw blade teeth. The band brush is located

inside the left bandwheel door. It is attached to a

bracket that is mounted to the saw head frame.

2. The brush must be properly adjusted to clean blade

tooth gullets if satisfactory sawing performance

is to be obtained. As bristles wear down, adjust

brush position by: (a) Loosening the bolts holding

the bracket to the saw head; (b) Move the brush to

the correct cleaning position; (c) Retightening the

bracket bolts.

Band Brush.

NEVER adjust the band brush while the saw

band is running.

Chip Removal

1. Metal fragments removed from the band brush and

from the stockpiece drop onto the saw base. The

chips ow with the coolant and drop into the coolant

trough. The ushing hose helps collect the chips

into the trough. Chip collections should be removed

from the trough when necessary.

• An optional chip conveyor can be used to remove

chips from this area automatically.

Loading...

Loading...