11

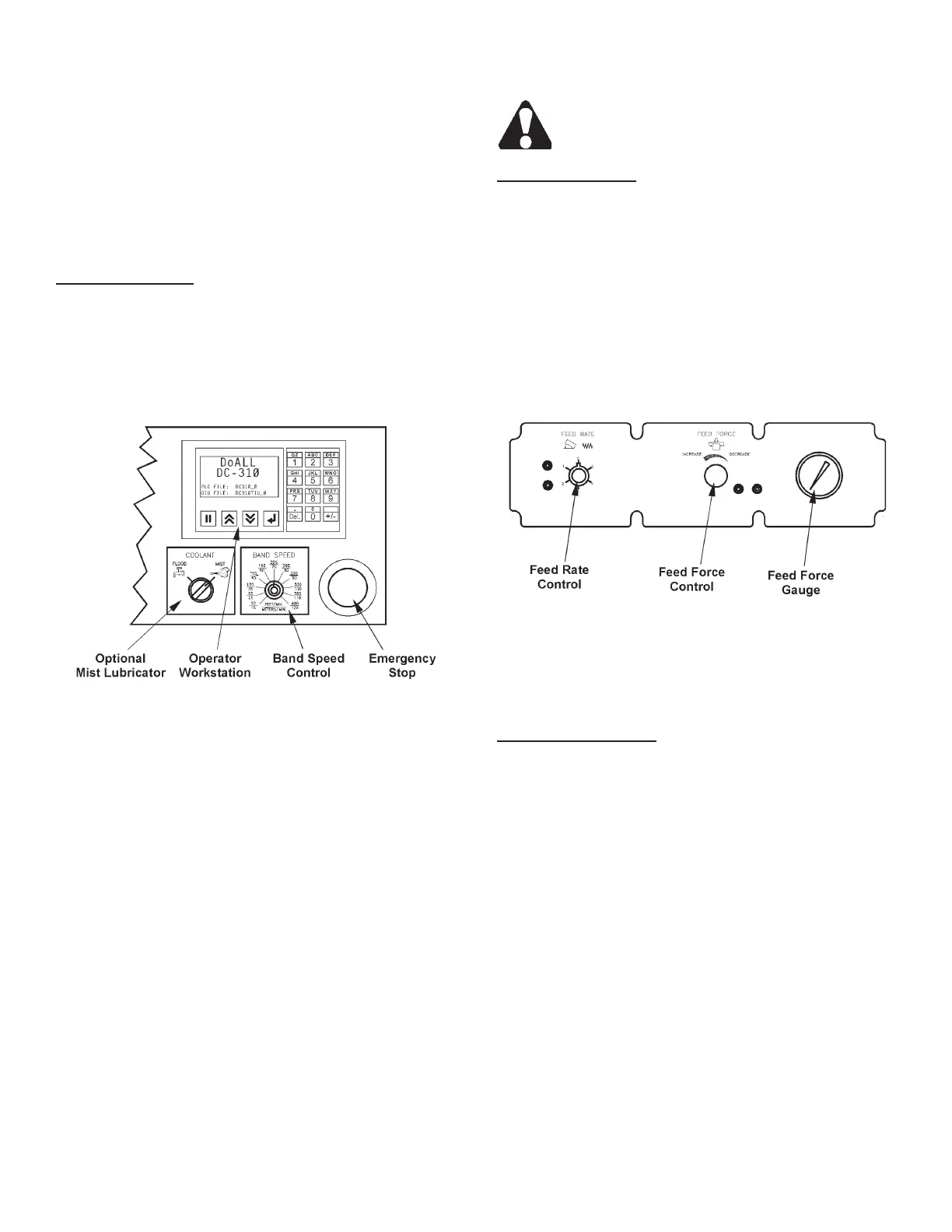

MACHINE CONTROLS

1. Machine controls are located on top of the electrical

box enclosure on the left front of the machine. These

controls include: (a) A hydraulic control panel with

a Feed Rate control and Feed Force control and

Gauge; (b) A control panel that includes a Emer-

gency Stop pushbutton; a Band Speed control and

an Operator Workstation to operate all other saw

functions.

Electrical Controls

1. Emergency Stop. Pushing this red mushroom

head button stops all machine motors (band drive,

hydraulic pump, coolant pump and optional chip

conveyor) simultaneously. This button must be

released or reset (rotate button head clockwise)

before the machine can be restarted.

Electrical Controls.

2. Band Speed. Band speed is innitely variable

between 50 and 400 fpm (15 and 120 m/min).

To adjust, turn the band speed knob clockwise

to "increase" band speed; counterclockwise to

"decrease" it.

3. Coolant (Optional). This selector switch allows

the operator to select between the standard "ood"

coolant or the optional "mist" lubricator system.

4. Operator Workstation. The workstation is program-

mable to allow data entry by means of a numeric

keypad. Also there is a display to show important

saw paramters and operation data.

• See "Operator Workstation" later in this section for

complete descriptions and operation of the worksta-

tion.

5. A Disconnect Switch is located on the control box

enclosure.

Turn the disconnect switch to OFF before

opening the electrical enclosure.

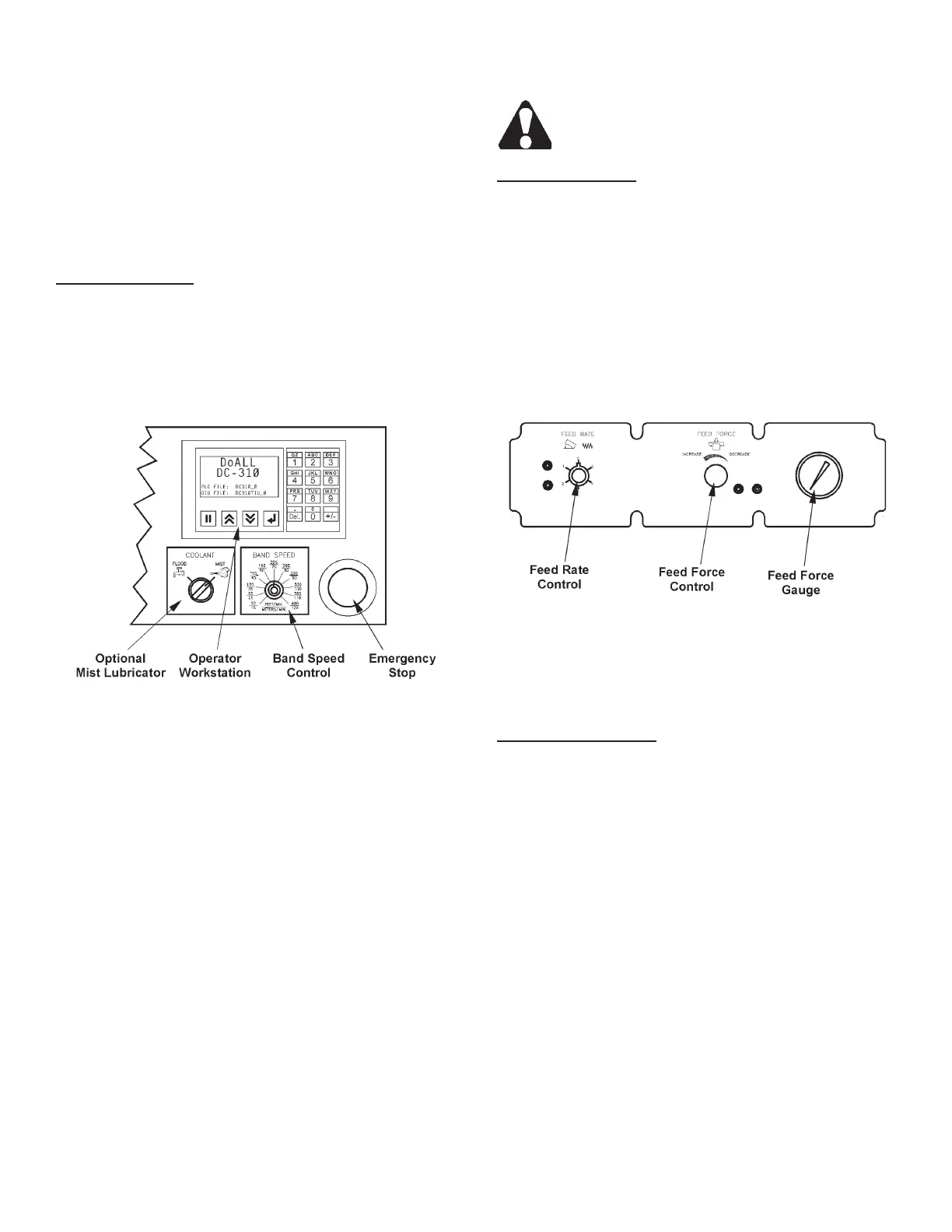

Hydraulic Controls

1. Feed Rate. This valve regulates the saw head’s

descending rate. Turn the knob counterclockwise

to “increase” the velocity; clockwise to “decrease”

it.

2. Feed Force. This valve regulates the amount of

pressure being placed by the saw band against the

workpiece. Turn the knob clockwise to “decrease”

pressure; counterclockwise to “increase” it. The

valve’s lower locking knob helps maintain the set-

ting.

Hydraulic Control Panel.

3. Feed Force Indicator. This gauge shows the

amount of pressure being placed by the saw band

against the workpiece.

Operator Workstation

1. The workstation consists of a numeric keypad for

entering data, a display for showing data and set

of four (4) function keys.

2. The function keys operate as follows:

• Data Enter. Pressing this key allows the operator

to enter data into the display.

• Previous Screen. This key allows the operator to

scroll "back" to the previous screen. Pressing the

key again will continue to scroll "back" until you

reach the "start-up" screen. It will not scroll "back"

any further.

Loading...

Loading...