34

NESTING FIXTURE

1. This optional feature is designed for high-production,

multiple sawing of stacked bars, rounds and tubing.

Its jaws have the capacity to hold stock up to 12.00

inches (304.8 mm) wide and 12.00 inches (304.8

mm) high. Minimum height is seven (7) inches

(177.8 mm).

2. The standard bundle xture clamps the material

eleven (11) inches (279.4 mm) in front of the saw

band; 13.00 inches (330.2 mm) behind the saw

band with a minimum butt end length in automatic

of 13.00 inche (330.2 mm).

3. The short cut bundle xture clamps the material

two (12) inches (50.8 mm) in front of the saw band;

13.00 inches (330.2 mm) behind the saw band with

a minimum butt end length in automatic of 13.00

inche (330.2 mm). This also includes various clamp

bar sizes.

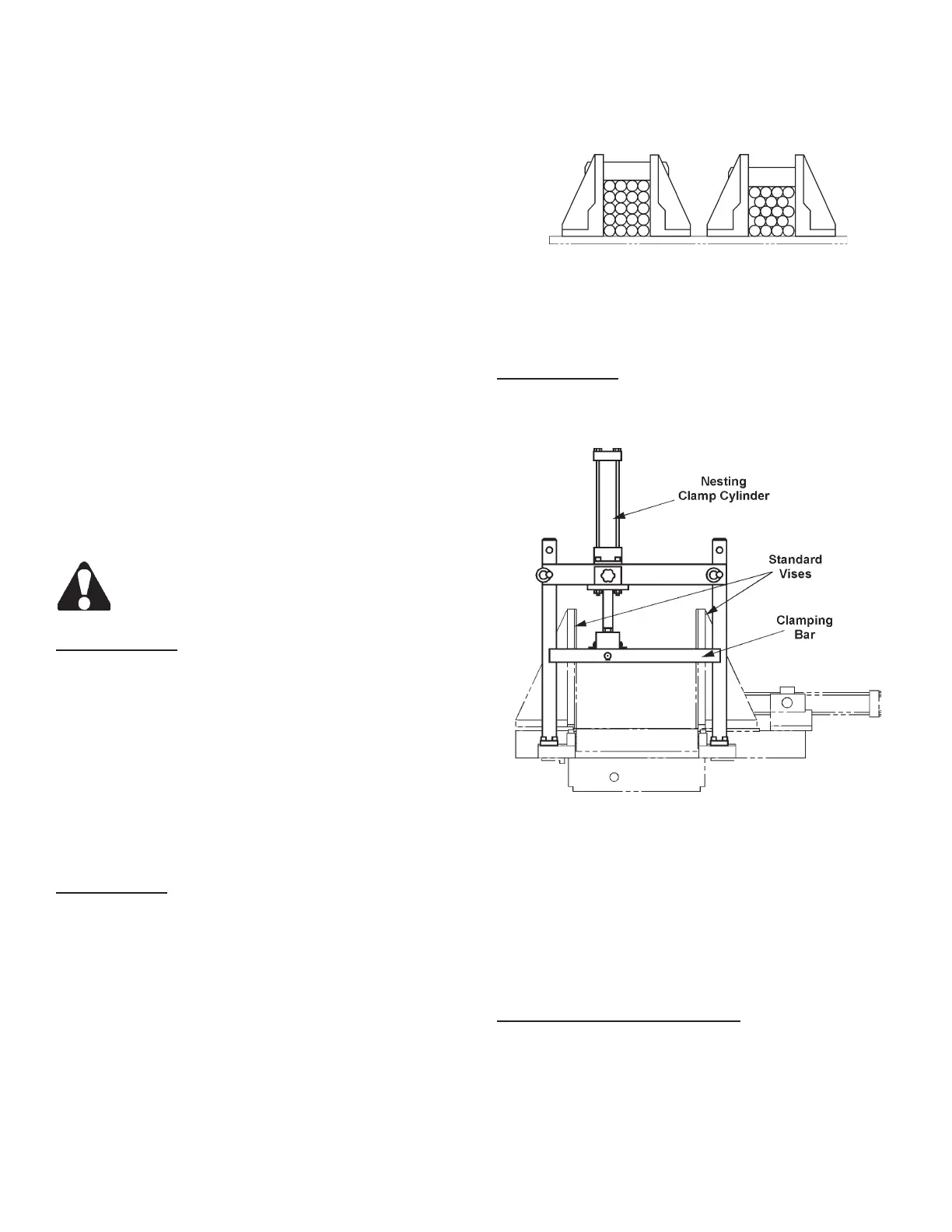

4. Vertical nesting clamp cylinders are mounted to the

machine’s front and index vises. The cylinders op-

erate simultaneously with the regular vise clamping

cylinders.

Thehydraulically-operatedNestingFixturecan

also be used with the Variable Vise Pressure

control.

Control Console

1. Scroll to the rst screen. Press the "7" key to see

the MACHINE SETUP group of sub-menus.

• Press the "6" key for NESTING ON vise sequence

which allows a time delay for the nesting clamp bar

to clamp the material. One vise is always clamped

to keep the bundled material in place.

• Press the "4" key for NESTING OFF disables the

nesting clamp bar from operating.

Stacking Stock

1. Correct stock nesting is essential for proper clamp-

ing of the vises and nesting xture. It is important

that nesting vise clamping pressure be transmitted

to every stacked piece. Sometimes this can be

more easily accomplished by manually jogging the

stack.

2. Proper stacking of round stock is important because

saw band breakage may occur if round nested pieces

slip or spin during sawing.

3. Two (2) workable round stock stacking methods are

shown in the next illustration (using the same num-

ber of rounds in each row usually provides the best

sawing results, although the alternate method can

be used if the material is not stacked too high).

Round Stock Stacking Methods.

4. Pieces should be stacked as closely together as pos-

sible. Metal chips lodged in open spaces between

individual pieces will affect cutting accuracy.

Vise Adjustment

1. Stack stock to be cut between the machine’s vise

jaws and then clamp the xed and index vises.

Nesting Fixture.

2. Use the correct size horizontal clamp bars com-

mensurate with the size of the nested stock.

3. If the horizontal clamping vises and the vertical

nesting clamp do not release at approximately the

same time: (a) Adjust the hydraulic restrictor valve

at the rod end of the vise clamp cylinders to achieve

relatively equal release.

For Best Nesting Cutting Results

1. Total stack width should be no more than ve (5)

to six (6) inches (127.0 to 152.4 mm).

2. Stack the same number of stockpieces in each

row.

Loading...

Loading...