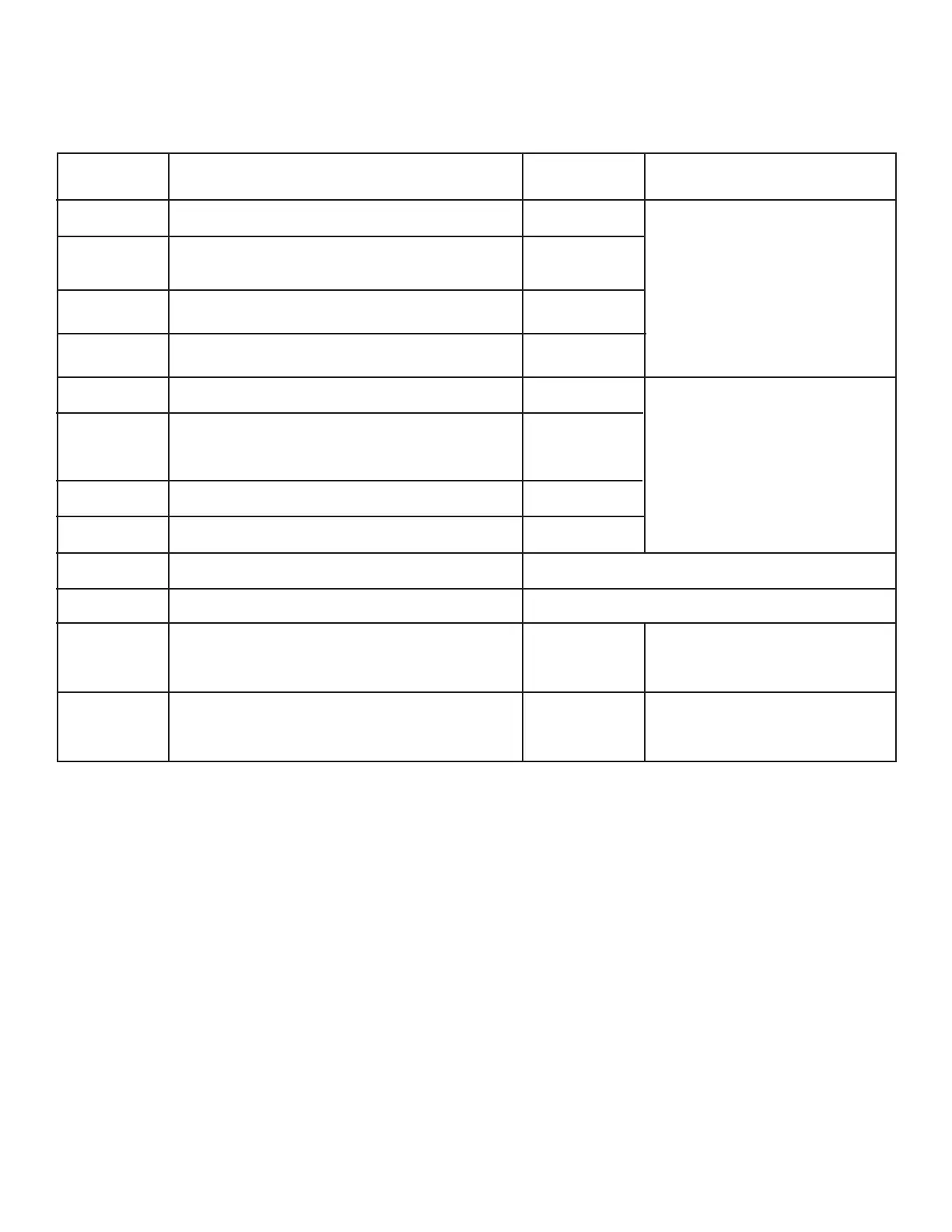

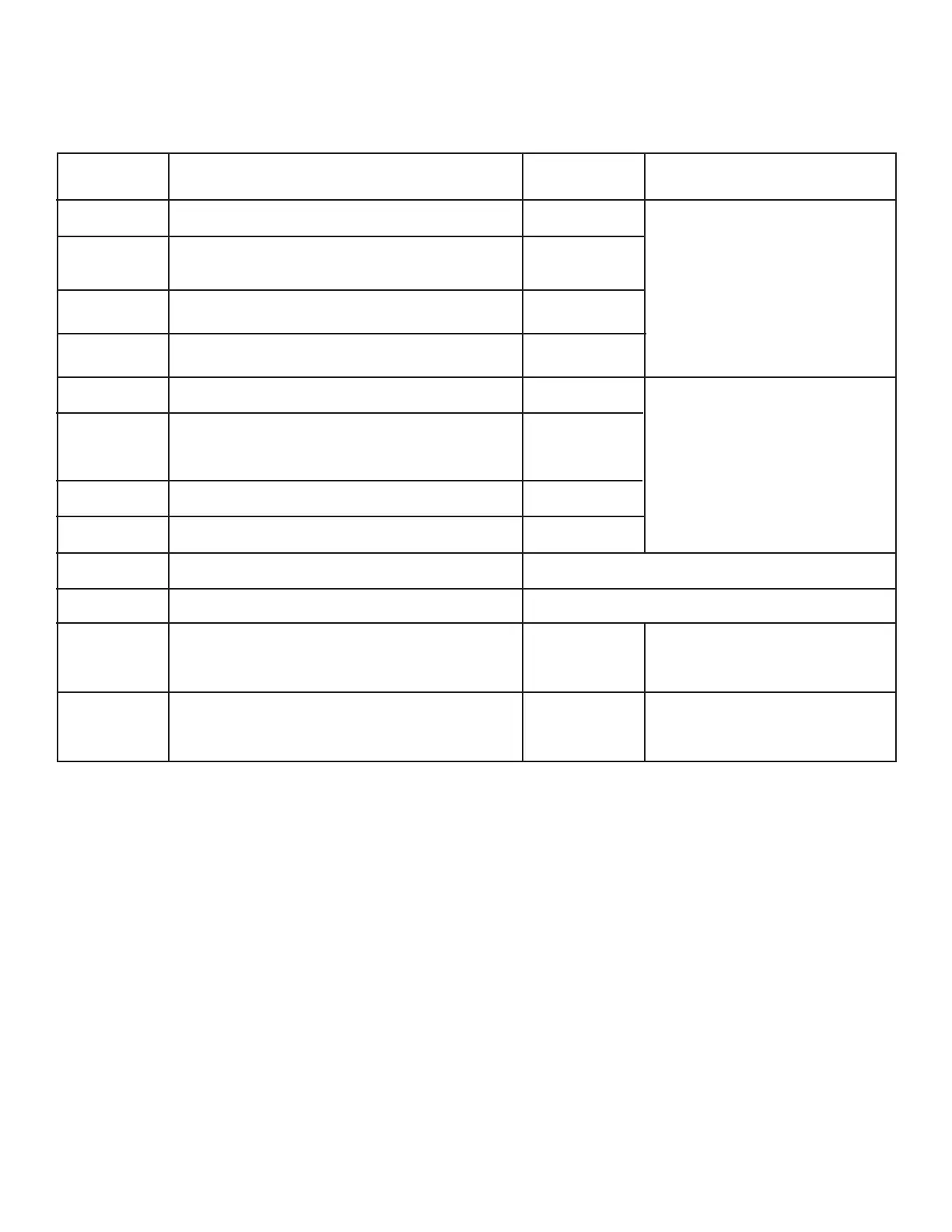

24

LUBRICATION

LUBRICATION CHART

LOCATION DESCRIPTION AND

SERVICE RECOMMENDATIONS

RECOMMENDED

LUBRICANT

LUBRICATION

INTERVAL*

LUBRICATION

POINT NO.

High quality, rust and oxidation-inhibited,

medium hydraulic and general purpose

industrial oil.

ISO-VG Grade 68 (Formerly ASTM Grade

No. 315).

Union 76, UNAX RX 68, or equivalent.

Premium quality, multi-purpose lithium-

base, EP (extreme pressure) grease.

NLGI No. 2.

Union 76, UNOBA EP 2, or equivalent.

Drive Shaft Bearings. Two (2) grease ttings.

Remove head tube end cap to access.

1

AS REQUIRED

Saw Guide Arm Slide. Clean and apply oil.

Micellaneous: Vise Slide, Hinges, Pivot Points, etc.

To ensure function and maintain appearance while reduc-

ing wear, corrosion, rust, etc., apply when and where

needed in appropriate amounts required.

4

8

WEEKLY

2

6

3

IndexViseLinearBearings. Four (4) grease ttings.

Secondary Roller Linear Bearings. Two (2) grease

ttings.

Saw Guide Adjustment Screws. Clean and apply oil.

Idler Bandwheel Slide and Screw Bearings. Apply

grease to slide.

6 MONTHS

MONTHLY

Electric/Hydraulic Motors. Oil cup and/or grease ttings.

9

Lubricate (if any) per manufacturer's recommendations.

Mist Lubricator (Optional).

10

Premium quality, saw band coolant and

lubricant.

DoALL cutting uids and/or oils.

Coolant Reservoir. 19 gallon (71.9 liter) capacity. Drain,

clean and rell whenever coolant becomes undesirable

for further use. Clean the mesh screen at the same time.

11

CHECK DAILY/

AS REQUIRED

* Lubrication intervals are based on a 8-hour day, 40-hour week.

Lubricate more often with heavier use.

Hydraulic System. Ten (10) gallon (37.8 liter) capacity.

Check uid level daily and keep the reservoir full. Drain,

change the lter element and rell after the 1st month;

every six (6) months thereafter.

CHECK DAILY/

AS REQUIRED

Multi-purpose automatic transmission

uid.

7

INSERT CHANGE

WEEKLY

Saw Head Linear Bearings. Four (4) grease ttings.

12

Lubricate (if any) per manufacturer's recommendations.

5

Sensing Arm. Clean and brush oil as needed.

MONTHLY

MONTHLY

Loading...

Loading...