35

3. The stack should always be higher than it is wide.

4. Apply as much coolant as possible while cutting.

5. Replace wear plates on the moveable vise jaw and

nesting xture’s vertical clamping jaw when they

become worn.

6. Generally, reduced band speed and feed rate are

necessary when sawing stacked materials. This

results in a lower cutting rate than possible when

sawing solid stock.

7. In some instances, increased production and blade

life may be obtained by nesting fewer pieces than

maximum vise capacity permits.

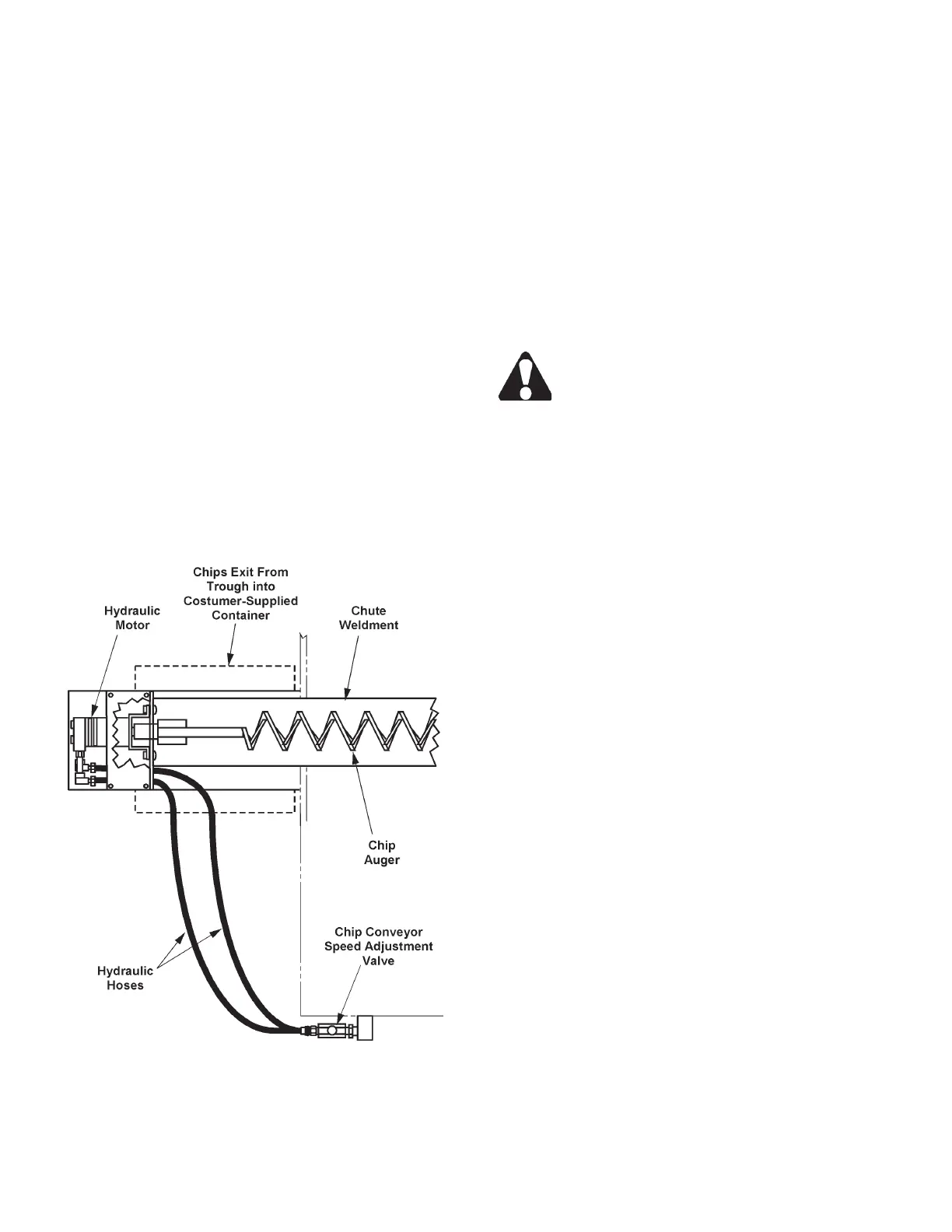

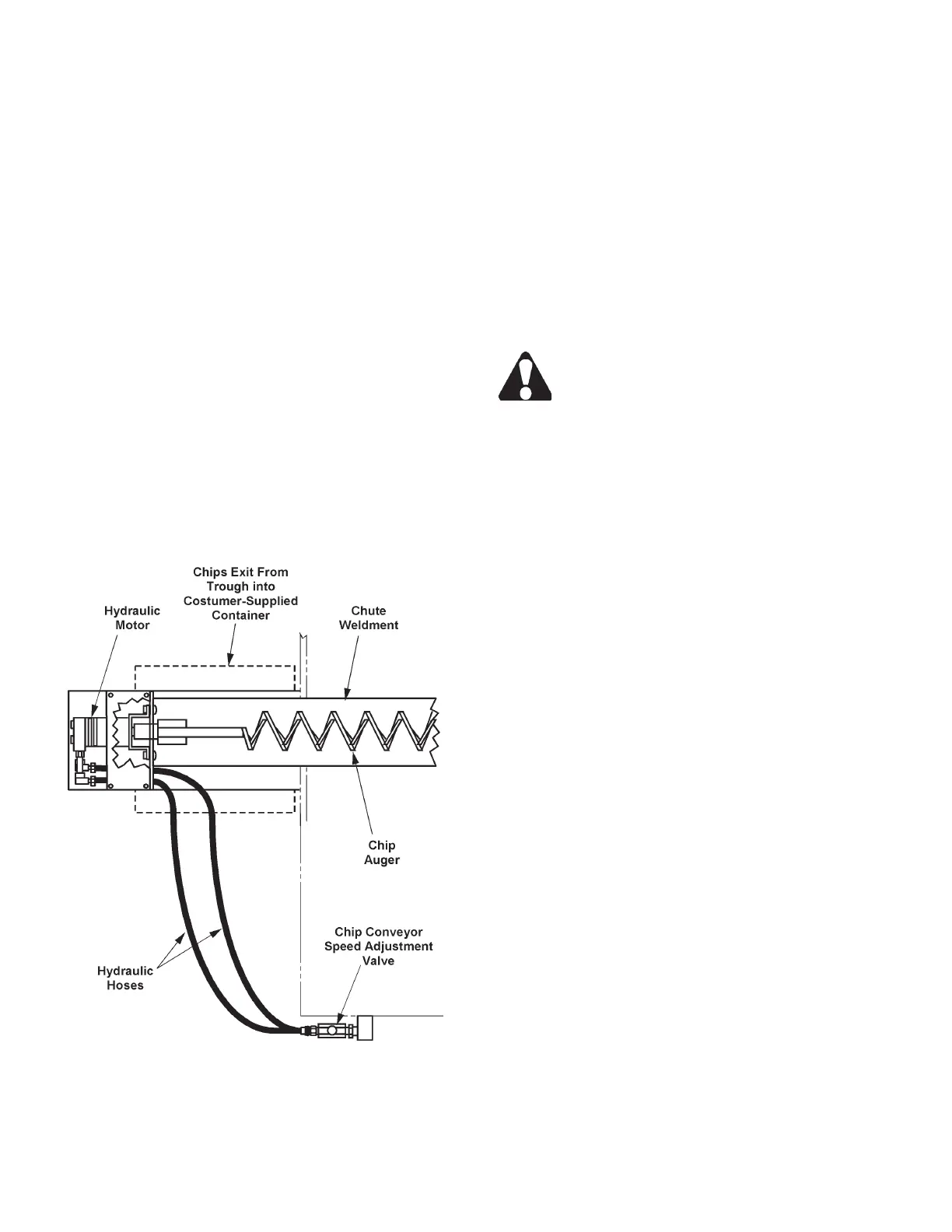

CHIP CONVEYOR

1. During operation, metal chips and used coolant

drop directly into a sloped trough, or ow into it

from the machine's run-off surfaces. Coolant then

ows down the trough and through a ltering screen

before returning to the reservoir.

Chip Conveyor.

2. The chip conveyor motor operates simultaneously

with the hydraulic pump motor. The conveyor screw

rotates slowly at the bottom of the trough. Its

movement carries metal chips to the opening at

the machine's right side where chips empty into a

customer-supplied container.

3. A valve located on the left rear of the saw base

allows the chip conveyor motor to be adjusted for

faster or slower operation.

MIST LUBRICATOR

1. Plant air supply at 80 to 90 psi (5.62 to 6.33 kg/cm²)

is required to operate this option.

DO NOT exceed 90 psi (6.33 kg/cm²) air

pressure.

2. See the instructions sent with the unit for

information on operation and adjustments.

WORKLIGHT

1. The worklight illuminates the cutting area for better

visibility and safety. It has its own "on-off" switch

mounted on the light.

MATERIAL HANDLING

1. DoALL Company manufactures conveyors, chain

transfers, workstops, lift rollers and material han-

dling products that enhance saw throughput, crane

efciency and workplace safety. Please consult

the factory for solutions to your material handling

application.

NESTING FIXTURE (Continued....)

Loading...

Loading...