28

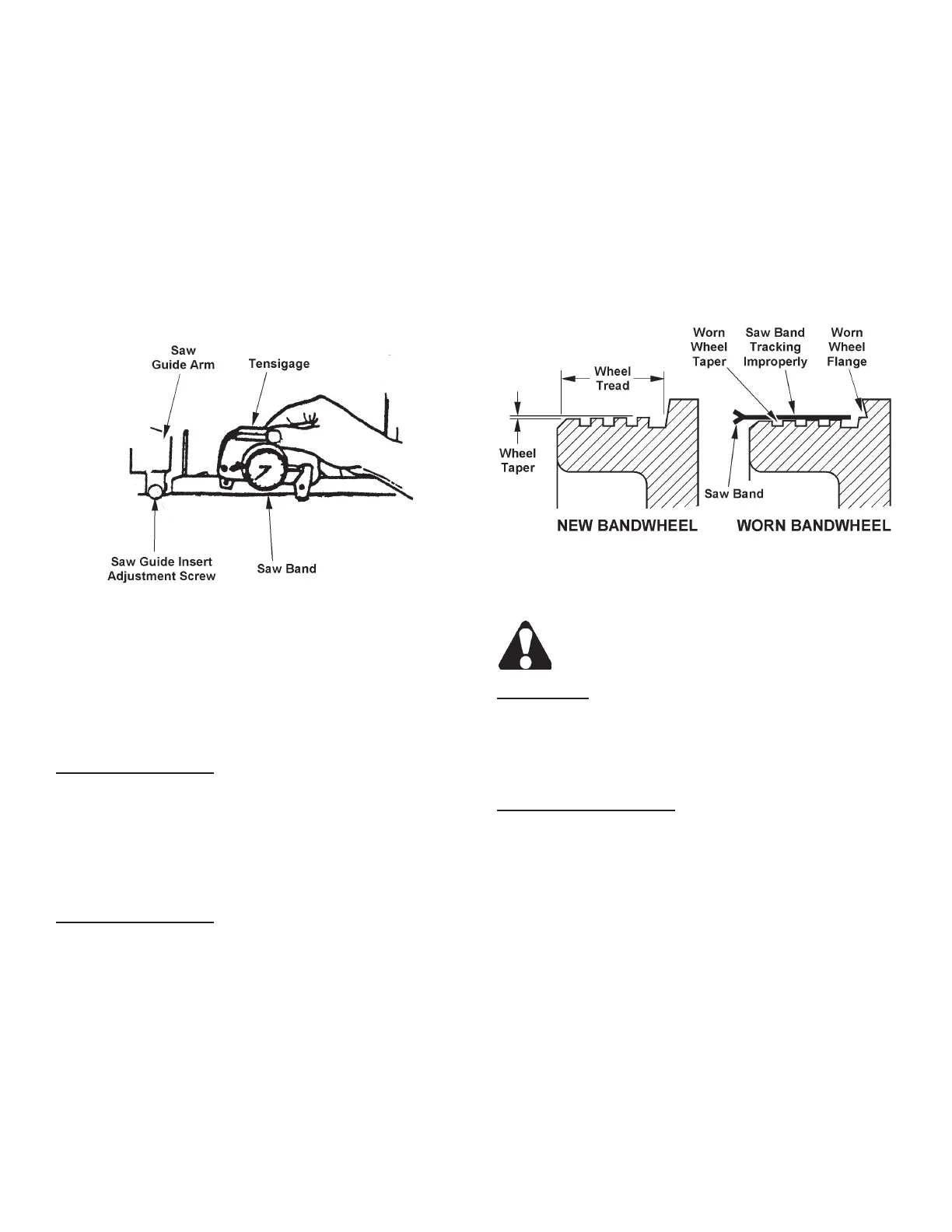

BAND TENSION MEASUREMENT

1. Tension adjustment of the saw band will be nec-

essary from time to time. Adjustment is made by

turning the band tension handwheel extending from

the saw head's left side.

2. Correct band tension will stress a high-speed steel

saw band to 26,250 psi (1845.6 kg/cm²). This is

comparable to a DoALL Tensigage reading of "3.5".

Refer also to the band tensioning portion of the

"Operation" section of this manual.

3. A DoALL Tensigage reading of 3.5 indicates correct

saw band tension.

Using a Tensigage to Measure Band Tension.

WEAR PLATE REPLACEMENT

1. The wear plates must be replaced before excessive

wear causes the mounting screw heads to become

damaged and makes removal difcult.

Vise Jaw Wear Plates

1. The machine has a total of four (4) vise jaw wear

plates -- one (1) on each vise jaw. All wear plates

are mounted with low-head screws. Be sure the

vise jaws are separated and the machine turned

off when replacing the wear plates.

Vise Bed Wear Plates

1. All wear plates are mounted with low-head screws.

Replacement requires: (a) Disconnecting the

clamping cylinder from the movable vise jaw; (b)

Removing the movable vise jaw; (c) Removing the

mounting screws and then the wear plates.

2. After replacing the wear plates, reinstall the low-head

screws and the movable vise jaw and reconnect the

clamping cylinder.

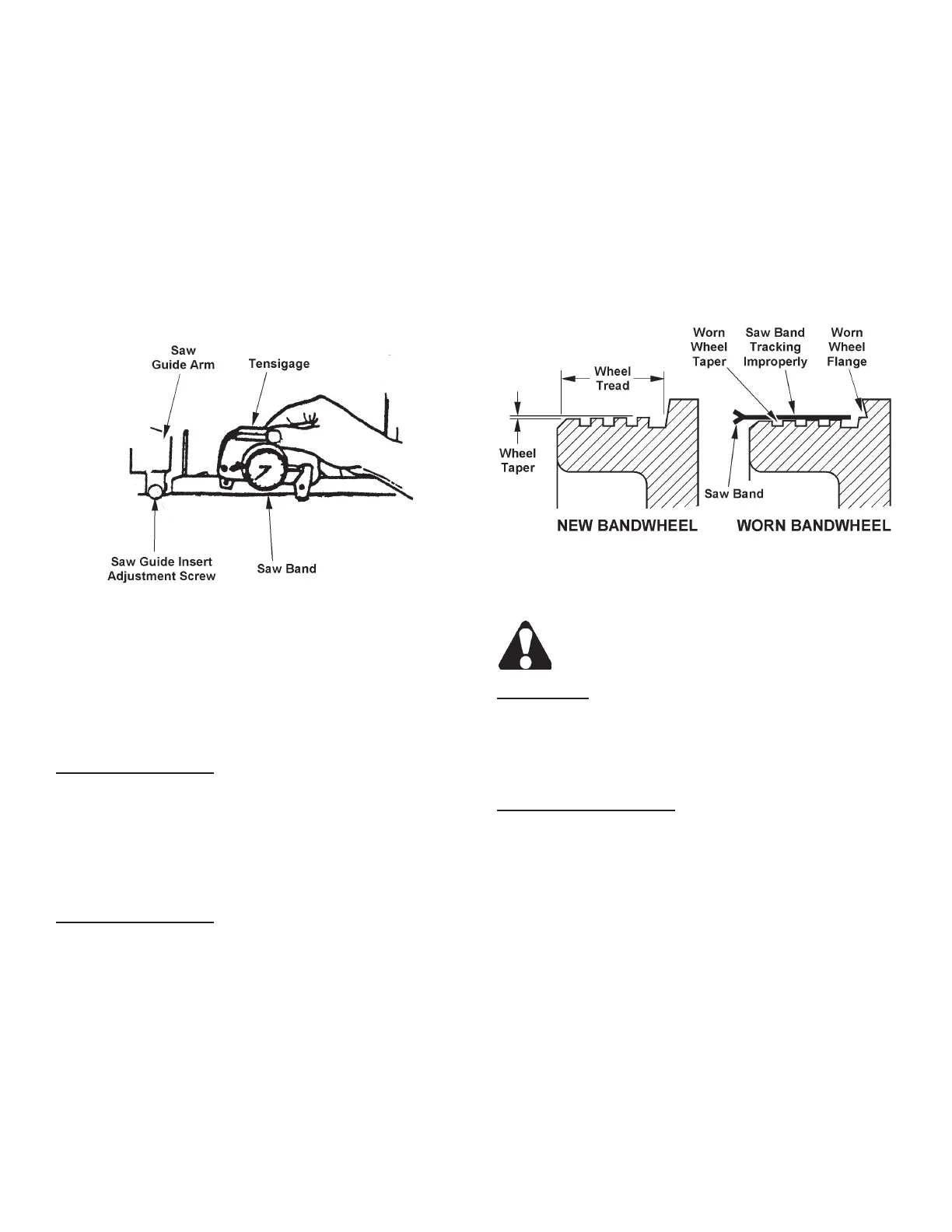

BANDWHEELS

1. Occasionally check each bandwheel’s back-up

ange and wheel tread for wear. Saw bands will

not track properly if the taper is worn from the wheel

tread.

2. Replace the entire bandwheel if the rim becomes

badly worn.

3. Ideally, the saw band should be tracking on both

wheels so that the back edge will just lightly contact

the wheel anges, or is not more than 0.005 inch

(0.127 mm) away from the anges.

Bandwheel Flange and Tread.

CLEANING CHIP TROUGH/CHIP CONVEYOR

The band drive motor must not be running

when cleaning the trough or chip conveyor.

Chip Trough

1. Chips may be removed using the shovel rake or

sliding out the entire trough and dumping the chips

into an approved container.

Optional Chip Conveyor

1. Disconnect the hydraulic hoses. Then: (a) Pull the

conveyor from its cradled position in the base; (b)

Clean the conveyor trough; (c) Clean the reservoir

oor; (d) Replace the conveyor.

Loading...

Loading...