19

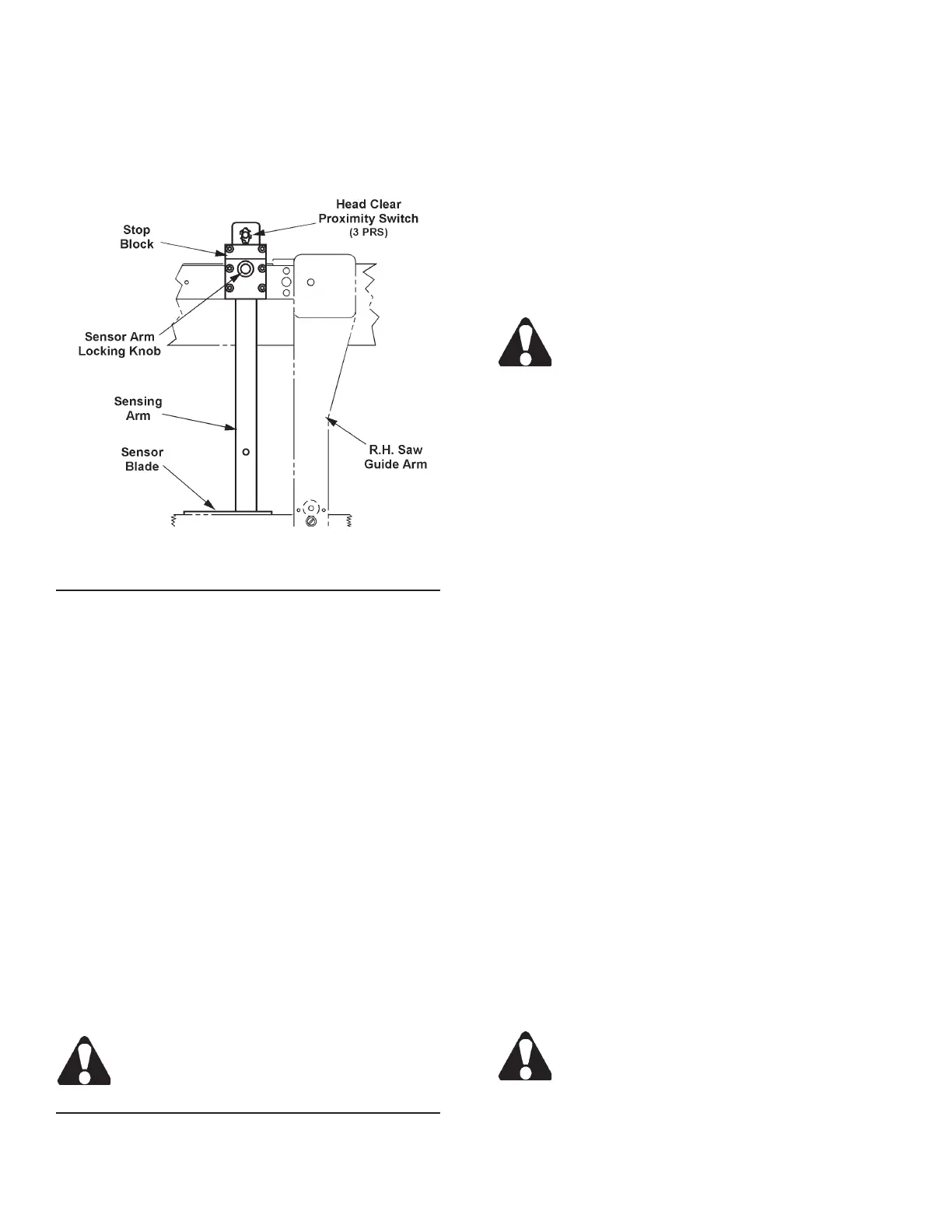

HEAD RAISE LIMIT SENSING ARM

1. The sensing arm works in conjunction with the

head clear proximity switch (3 PRS) to assure that

the saw head has raised sufciently above existing

stock so that automatic indexing (or manual stock

positioning) can be accomplished safely.

Head Raise Limit Sensing Arm.

Sensing Arm Operation When the Saw Head Raises

1. The saw head lifts the sensing arm above the stock

at a rapid rate (there is no slow head raising rate)

until it actuates the head clear proximity switch (3

PRS). This causes saw head upward movement

to stop when the blade is approximately one (1)

inch (25.4 mm) above the stock. This clearance

anticipates potentially crooked and/or out-of-round

stock being used.

2. If operating in automatic mode, the xed vise then

unclamps, and stock is indexed forward. Following

the advance of stock, the xed vise clamps and the

index vise unclamps.

3. When the xed vise unclamps prior to indexing, its

jaws open just enough to allow stock advancement.

The vise jaws can be opened wider only when the

saw head has been manually raised to the full "up"

position to actuate the head up proximity switch (2

PRS). This assures that the left saw guide arm will

clear the xed vise when it opens to receive larger

stock.

Left saw guide arm adjustment for stock width

must be made manually by the operator.

Sensing Arm Operation When the Saw Head Lowers

1. The saw head lowers until stock is contacted by the

sensing arm.

2. Sensing arm contact with the stock is maintained

throughout the cut. After a cut has been nished:

(a) The head down proximity switch (5 PRS) is

actuated; (b) The saw head raises.

VISE JAW ADJUSTMENT

1. The distance between the xed (right) and movable

(left) vise jaws can be adjusted to accommodate

varying stock widths. To adjust, scroll through the

screens until the INDEX VISE and FIXED VISE

controls are displayed. Then press the desired key

to open or clamp the vise jaws.

The hydraulics MUST be "on", the operation

mode MUST be in "manual" for the vise con-

trols to operate.

2. For index lengths between .50 and 1.75 inches

(12.7 and 44.4 mm), replace standard serrated wear

plate on the movable jaw of the outboard vise with

a recessed wear plate (box of extra parts).

MATERIAL INDEXING

1. Your machine is capable of a 16 inch (406.4 mm)

single stroke index (minimum is 0.50 inch (12.7

mm). It can also is capable of a 10X multiple index

up to a maximum length of 160 inches (4064.0

mm).

2. A movable roller assembly to help support the mate-

rial is located behind the index vise. It is connected

to the index vise by a rod that allows the roller to

move with the movement of the index vise.

3. Index length is set in the JOB ENTRY screen which

is on the rst screen . Press the "6" key on the

numeric keypad to access this screen.

• To enter data, press the Data Entry function key.

Then: (a) With the length eld highlighted, enter

the length of the cut using the numeric keypad; (b)

Press the Accept function key to enter the data

into memory; (c) With the quanitity eld highlighted,

enter the number of cuts using the numeric keypad;

(d) Press the Accept function key to enter the data

into memory;(e) With the next job's eld highlighted,

continue as above; (d) When there is no highlighted

eld, press the NextScreen key to move to the next

set of two (2) jobs to be programmed.

If you make an error in entering data, just press

the Data Enter key again, change your entry

and then press the Accept key.

Loading...

Loading...