INSTALLATION

A-12 20509 Issue 7 Jan 2018

PRODUCT DETECTOR INSTALLATION

A product detector is mounted where it can sense products as they

approach the printer (see

page 2-20).

Macrojet 2 can be fitted with one or two sensors. Allocation of print heads

to sensors is part of the data input to the printer, - see Pocket Terminal

User's Guide.

For basic coding, the product sensor should be positioned as close as

possible to the print head. Macrojet 2 is supplied with two clips which can

be fitted to the print head. They are attached to the "upstream" side using

the two screws already fitted into the print head cover.

The final print position is adjusted using the Print Go delay (part of the print

message input data) - see Pocket Terminal User's Guide.

Setting up the Print Go signal in the printer is automatic. Further

information is given in Part 3: Universal Serial Interface PCB.

Reflective

This detector is supplied as part of a Photocell Detector and Reflector kit.

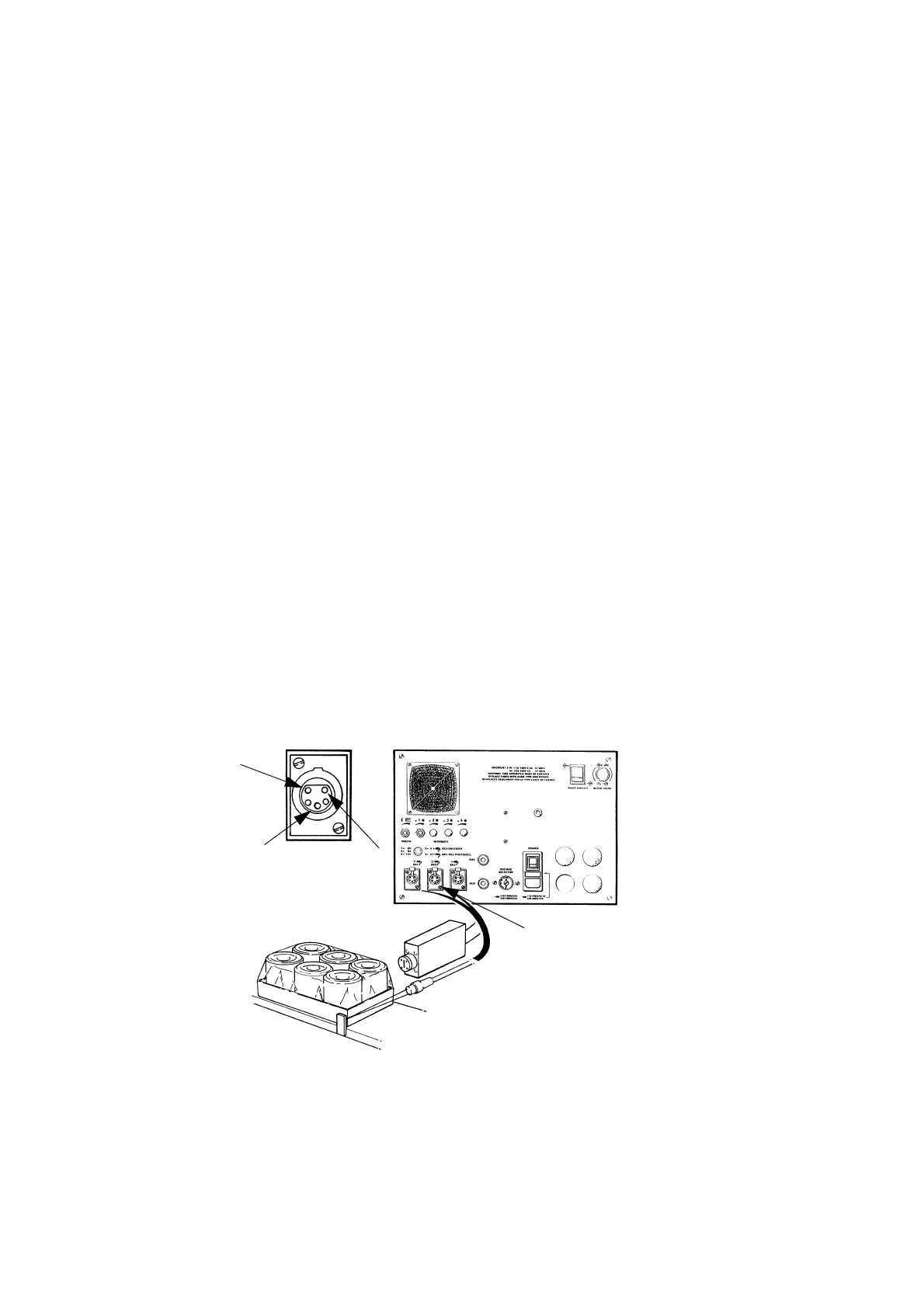

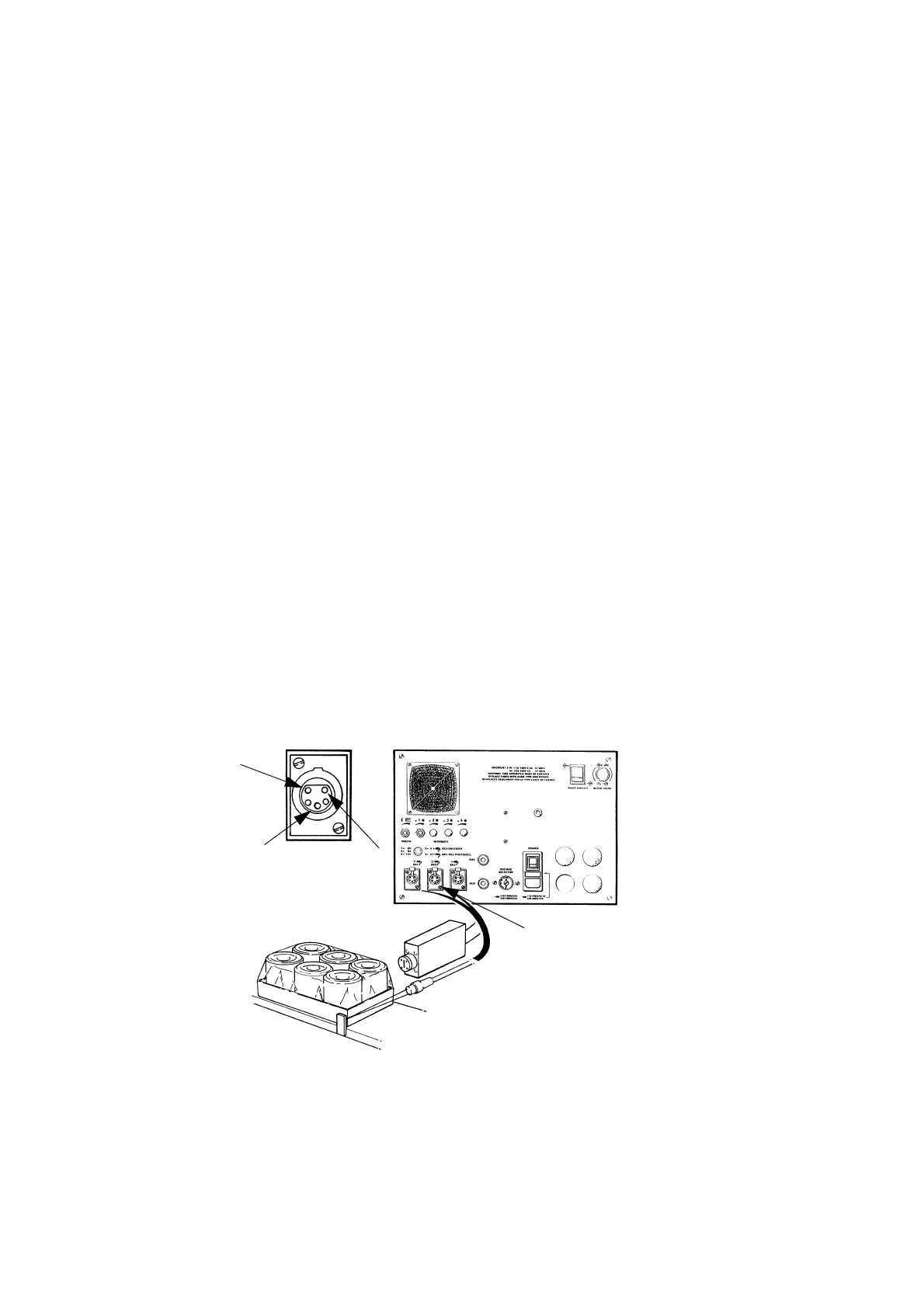

Connection details are given in the diagram below.

The detector and reflector are fitted on opposite sides of the product line.

The reflector is adjusted so that a light beam from the detector, directed

across the line, is reflected back into a photocell in the detector. Products

moving in between the detector and reflector break the light beam and this

is used to start the printing process, either as the beam is broken or as it is

restored. The basic requirement is, therefore, gaps between product items

as they pass the detector.

Pin 5 =

+12V

Pin 3 =

Print Go

Pin 1 = 0V

Product Detect

Inputs 1 & 2

Reflective Detector

TP7160_1

Loading...

Loading...