MAINTENANCE PROCEDURES

20509 Issue 7 Jan 2018 3-9

Checking Drop Size

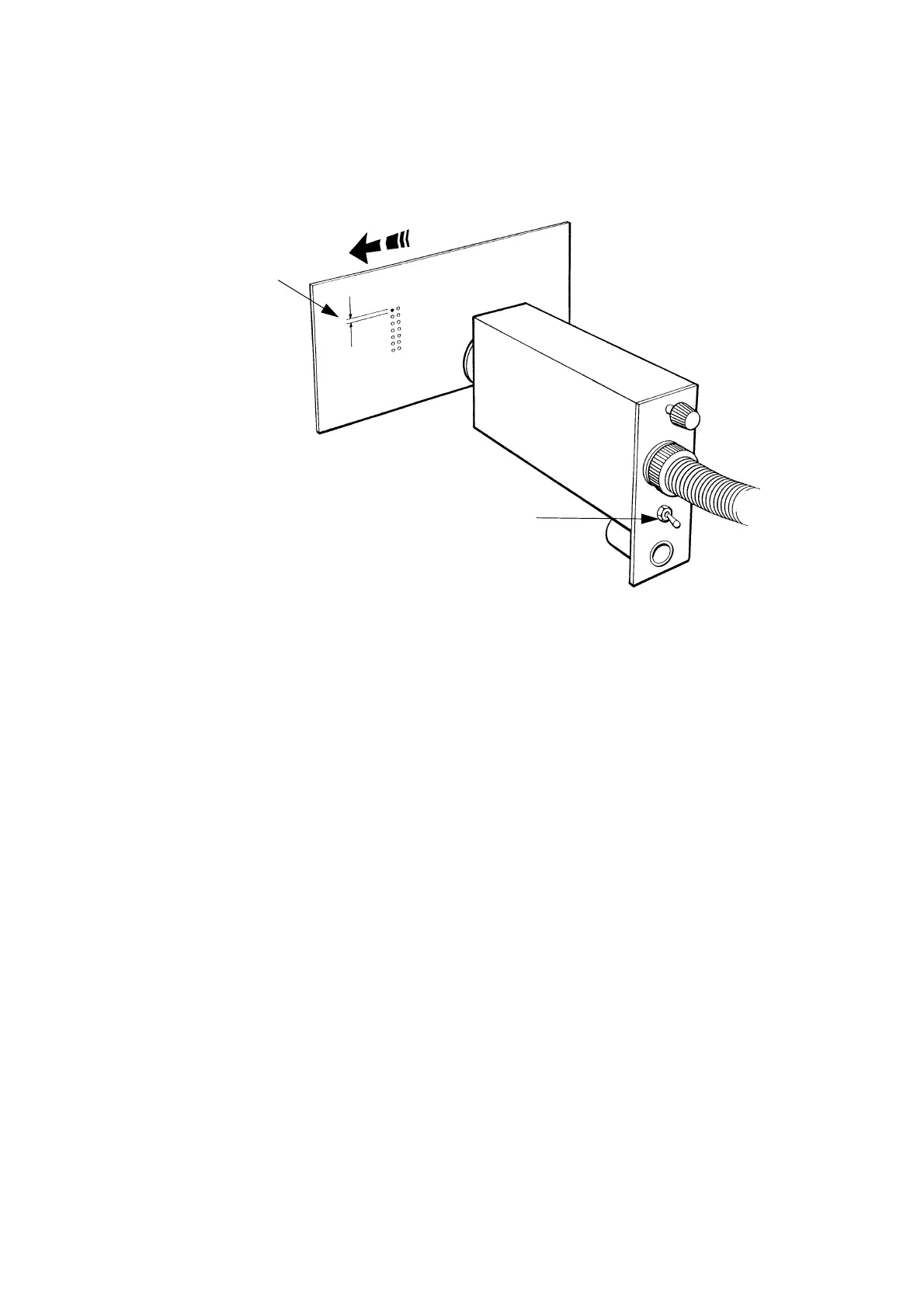

All dots printed by a print head must be the same diameter. The diameter

must be 2.5 to 3.0mm for 12, 16, 20, 32 & 50mm heads.

(1) Remove, clean and replace the nozzle plate (see page 4-9).

(2) Switch on the printer and turn the intensity control to maximum (fully

clockwise).

(3) Move a piece of card at a constant speed across the front of the print

head at a distance of 8 - 10mm. At the same time operate the purge

switch.

(4) With a little practice it will be possible to print a series of separate

strokes on the card.

(5) Inspect the strokes printed on the card. All strokes must be made up

of dots of the same diameter. The dot diameter must be within the

dimensions given above.

Note: If the dots are not uniform and the correct diameter, it will be

necessary to adjust the solenoids to change the size of the ink

drops (see below).

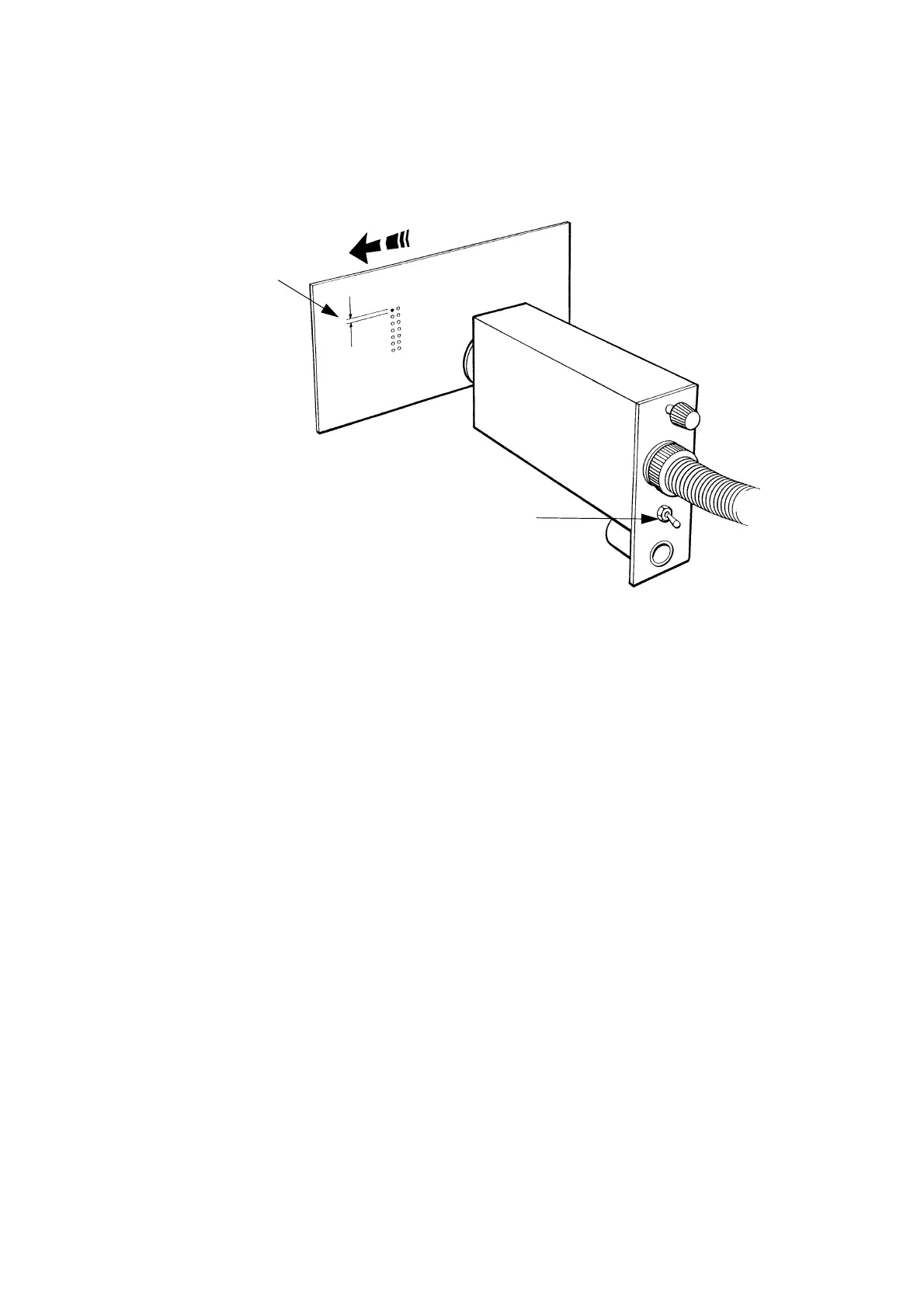

Adjusting Drop Size

All nozzles must produce drops of the same size. They are made to do so

by adjusting the solenoids.

The printer must be switched on and working correctly in all other respects.

It will be necessary to work inside the print head and to print on a moving

test surface at the correct distance. If necessary, fit the print head onto a

test mounting to do this.

Dot

Diameter

TP2103-1

Purge

Switch

Loading...

Loading...