DESCRIPTION

2-8 20509 Issue 7 Jan 2018

The ink that emerges from the nozzle forms a drop, ejected onto the print

surface by the ink pressure. Drop size, density and quality of the print is

controlled by three factors:

• The time for which the solenoid is energized

• The position of the slug when the solenoid is de-energized

• The ink pressure.

Ink flow into the head can be shut off with the print head valve. A purge

switch operates all the nozzles to remove any air (see

page 3-4).

The print head is mounted at right angles to the print surface, at a distance

of 3 to 5mm for best print quality. At distances outside these limits, print

quality will be reduced.

Macrojet 2 has a number of print head and print options. The print options

are shown in the diagrams (see

page 2-9 and page 2-10). A 7 drop head

will print only the single line options. A 16 drop head is required to print the

twinline and large options. Up to four lines of print (7x5), by way of four 7

drop heads or two 16 drop heads, can be supplied from a single control

cabinet

TP1291_1

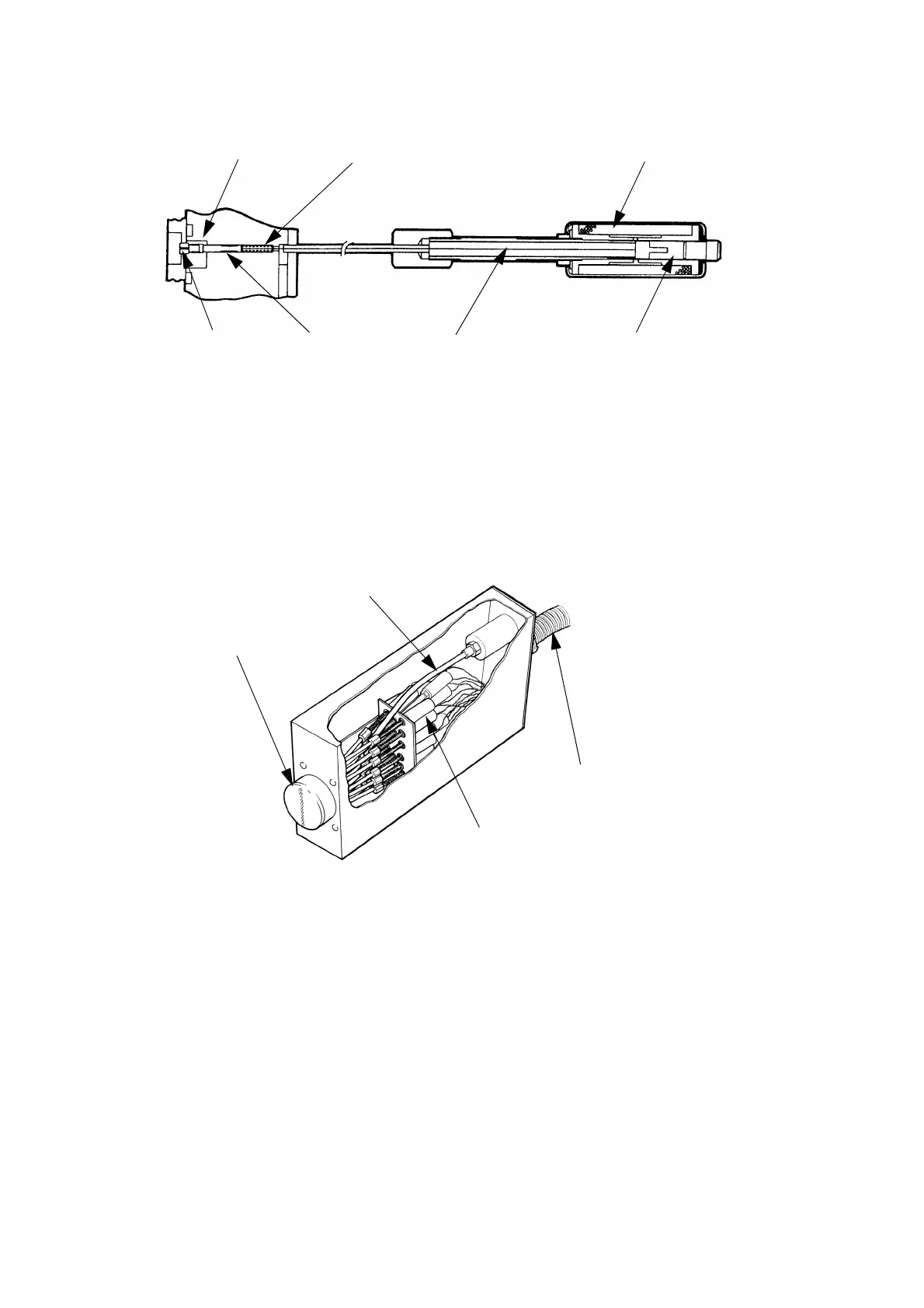

Plunger Slug Slug Return Spring Solenoid

Nozzle Plunger Control Wire Solenoid Slug

TP1380_1

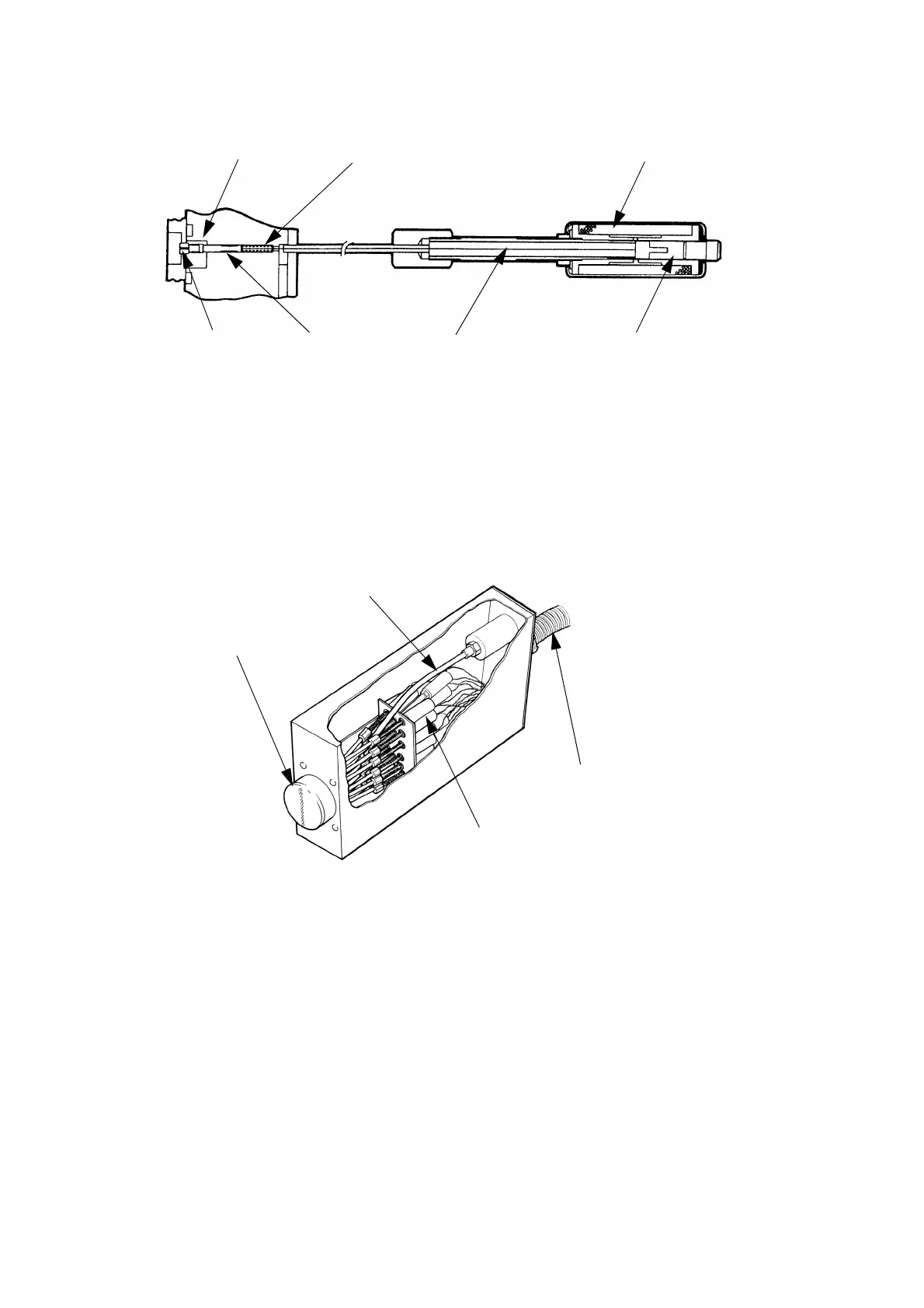

Nozzle Plate

Feed Pipe

Solenoids

Conduit

The Print Head

Loading...

Loading...