29

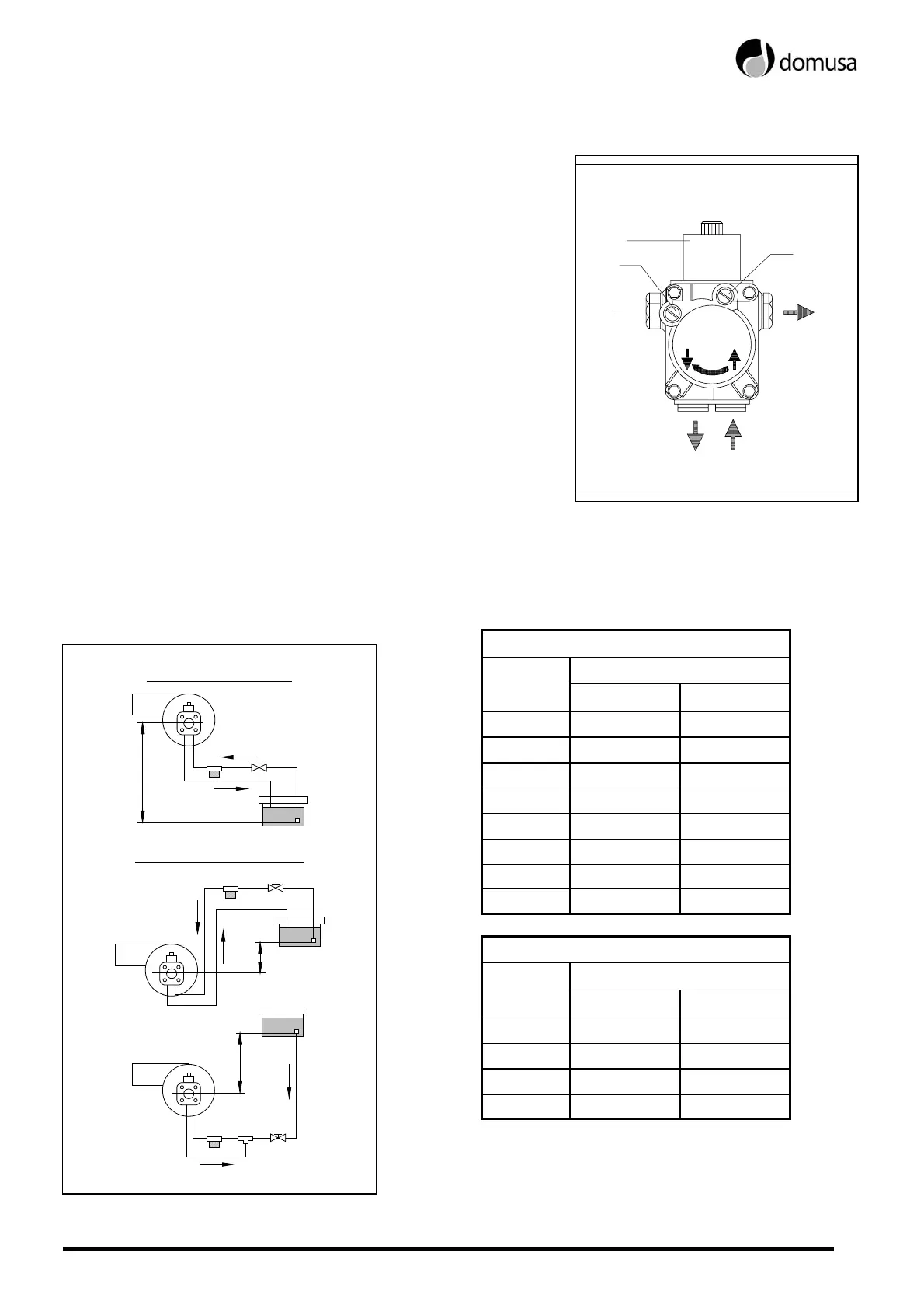

23.7 Oil pressure adjustment

To adjust the oil pump pressure, turn the screw

(1)

clockwise to increase the pressure, and

anticlockwise to decrease it.

1 - Pressure adjustment.

2 – Vacuum gauge point.

3 - Valve.

4 - Manometer point.

5 - Nozzle outlet.

6 - Return.

7 - Intake.

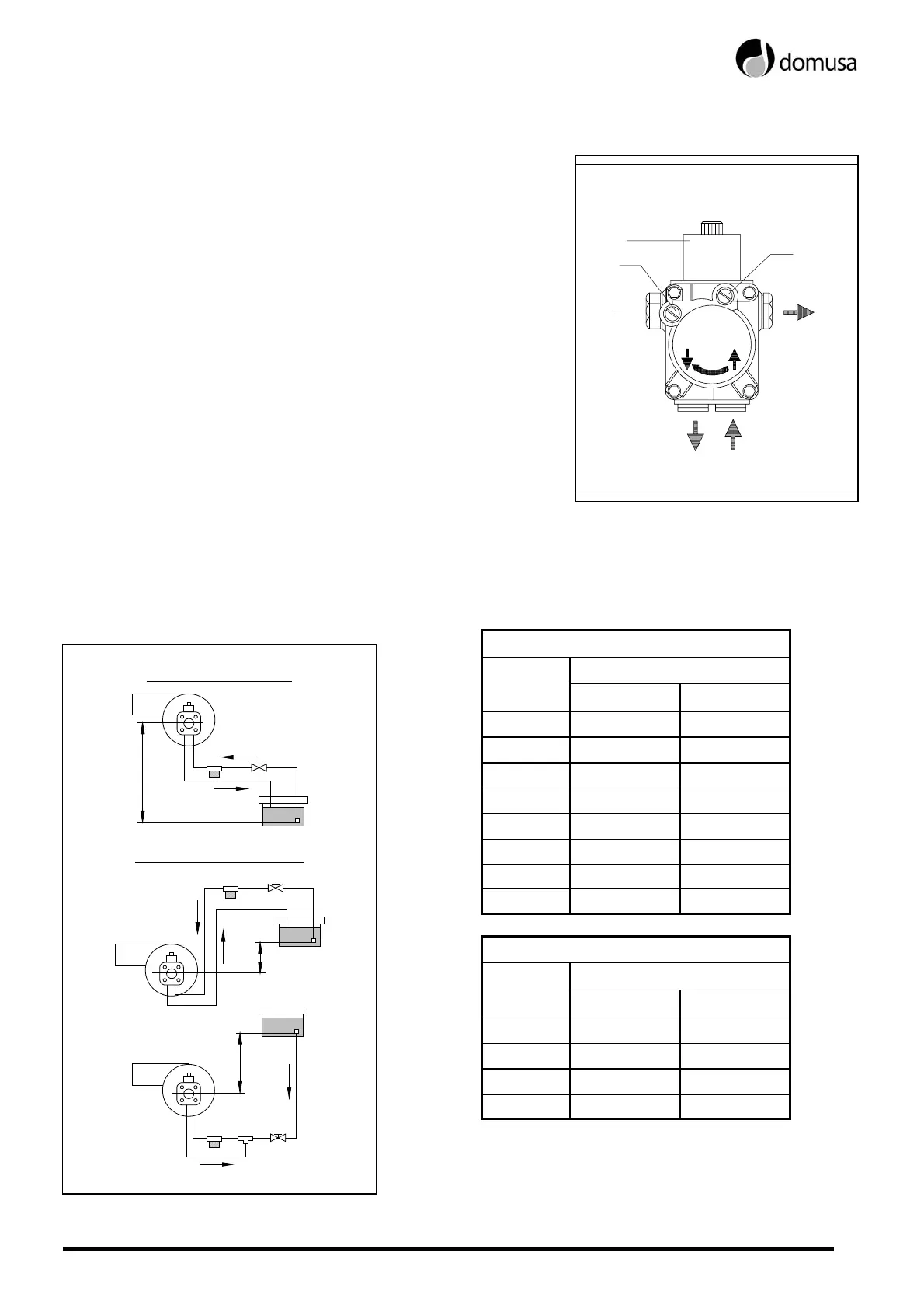

23.8 Oil supply piping diagrams

The diagrams and tables below correspond to installations without reductions and with a perfect

hydraulic seal. It is recommended to use copper pipes. A pressure drop of 0.4 bar (30 cmHg) must

not be exceeded.

Intake installation

H Pipe length

(m)

int.∅ 8 mm. int.∅ 10 mm.

0.0 25 60

0.5 21 50

1.0 18 44

1.5 15 38

2.0 12 26

2.5 10 26

3.0 8 20

3.5 6 16

Charging installation

H Pipe length

(m)

int.∅ 8 mm. int.∅ 10 mm.

0.5 10 20

1,0 20 40

1.5 40 80

2.0 60 100

WARNING: Check periodically the flexible pipes

conditions. Using kerosene, they have to be

replaced at least every 2 years.

MOD. AS47C

1

2

3

4

5

6

7

Intake installation

H

Charging installation

H

H

Loading...

Loading...