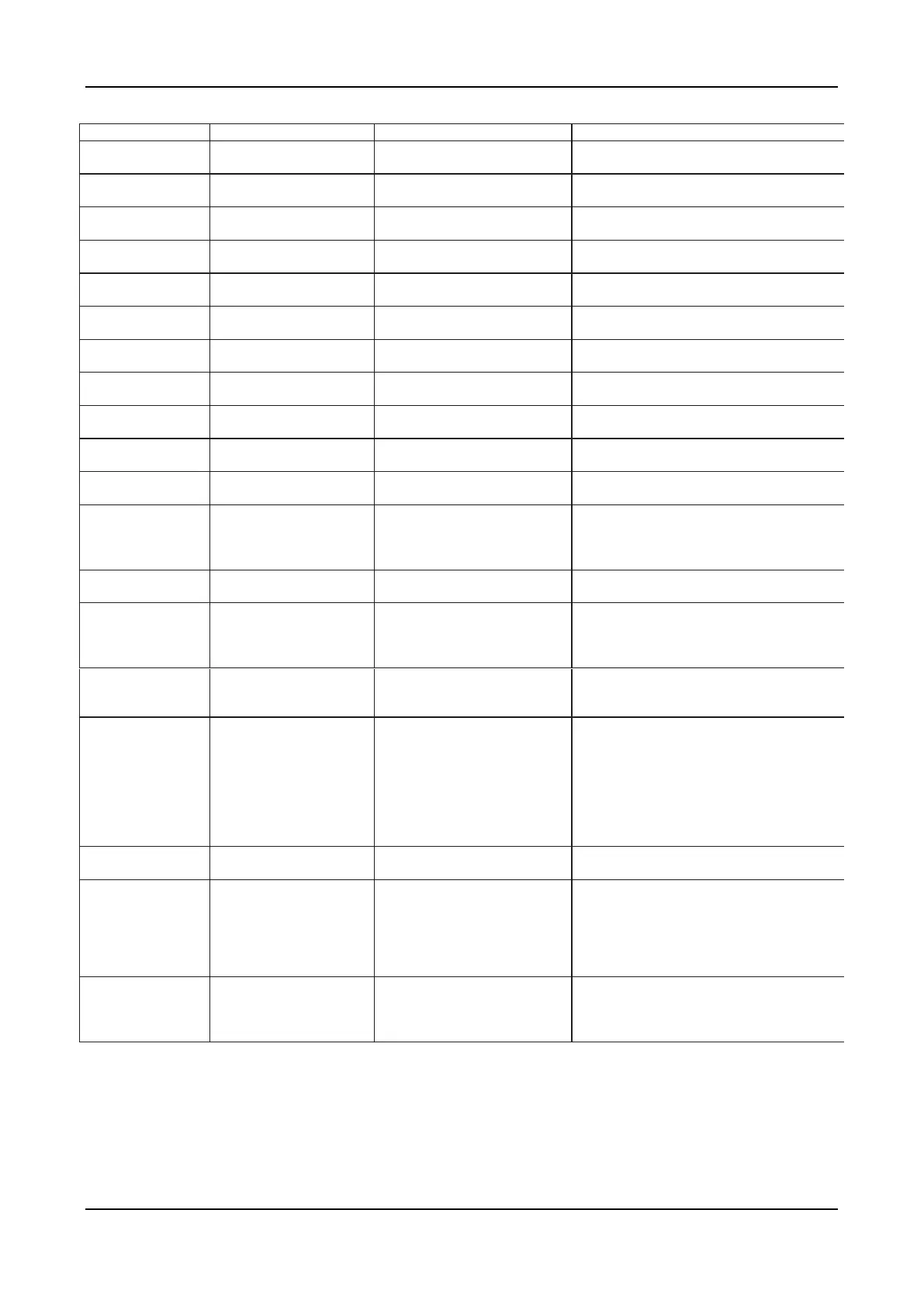

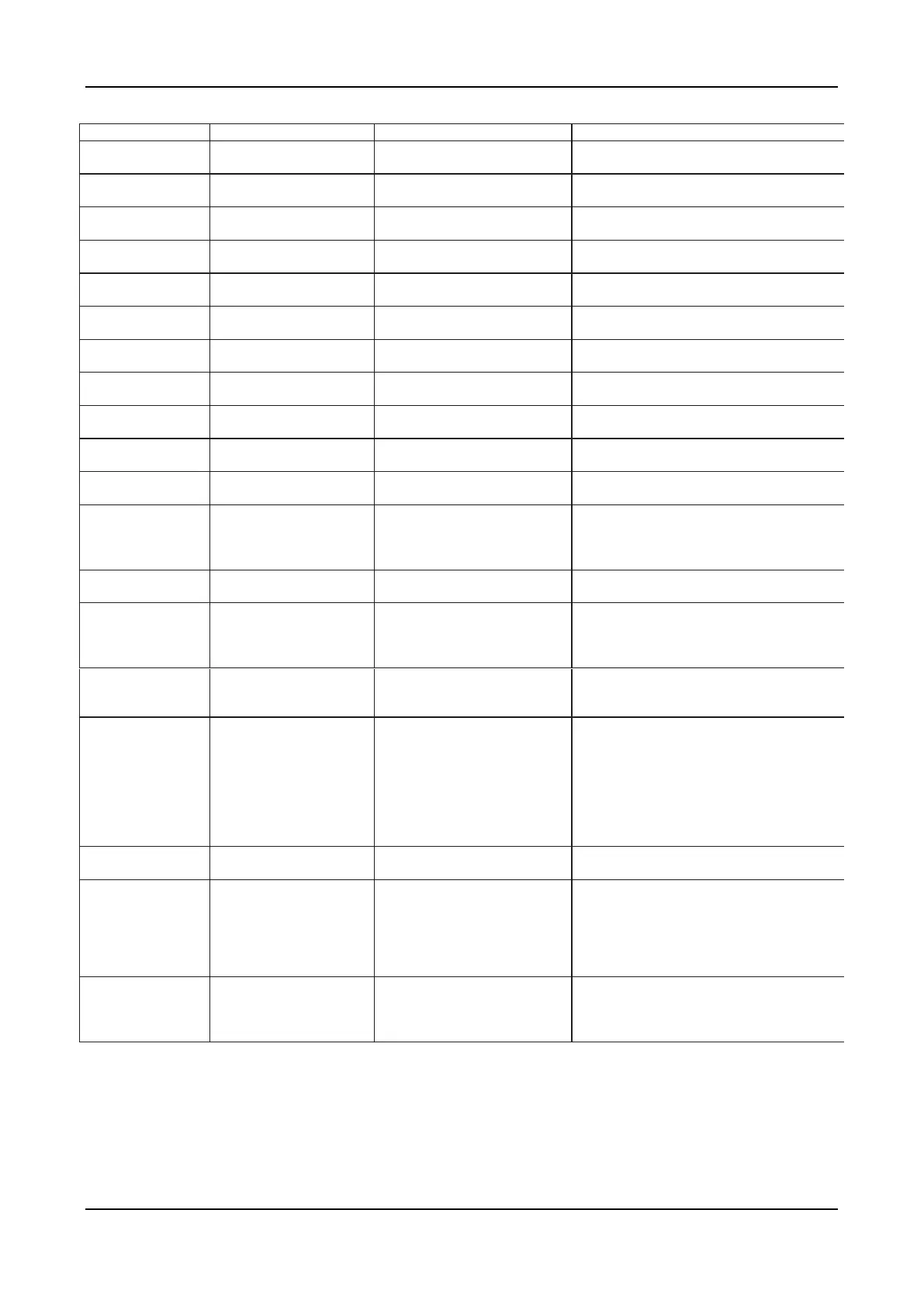

Troubleshooting

4.3-4

Recommended countermeasures

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

Body CAN network involves

BusOff

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

Tee water valve 1

communication loss

Tee water valve

communication loss

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

Tee water valve 2

communication loss

Tee water valve

communication loss

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

Compressor in failure status

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

Compressor

communication loss

Compressor communication

loss

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

Compressor

communication failure

Compressor communication

failure

1. Test the circuit. 2. Ask the professional

maintenance personnel for maintenance.

Compressor start-up

failed

Poor release or missing

phase of three-phase line

Replace the compressor (it is

recommended to notify the supplier to

check on site before replacing the

compressor).

Compressor hardware

protection

High compressor IPM

temperature

1. Poor heat dissipation; 2.

Too little refrigerant;

3. Leakage inside the

compressor.

1. Inspection the suction pressure,

exhaust pressure, and suction

temperature; 2. Replace the compressor.

Internal stall of

compressor

1. Dirty system; 2.Internal

damage of compressor; 3.

Impurities.

Replace the A/C compressor.

High compressor bus

current

1. High pressure switch

failure (component

failure/slow); 2. Excessive

refrigerant charging; 3.

Condenser fan inoperation.

1. Install the pressure sensor to the

vehicle. If the pressure rises, check the

A/C system. 2. High system pressure

(above 25 bar), so it is recommended to

add to the standard refrigerant volume

(30 ml recommended to be added after

refilling) ; 3. Check if the condenser fan is

working properly.

Low traction battery voltage

High compressor phase

current

1. Refrigerant slugging (high

instantaneous phase

current); 2. Refrigerant loop

blocked; 3. Much refrigerant;

4. Condenser fan damaged.

1. Re-vacuum and add refrigerant; 2.

High system pressure (above 25 bar), so

it is recommended to add to the standard

refrigerant volume (30 ml recommended

to be added after refilling) ; 3. Check if

the condenser fan is working properly.

Output voltage of the high

voltage terminal exceeds the

operating voltage range of

the compressor.

Check if the high input voltage of the

compressor is higher than 405 V.

Loading...

Loading...