OPERATING INSTRUCTIONS

16

7/71, 12/56

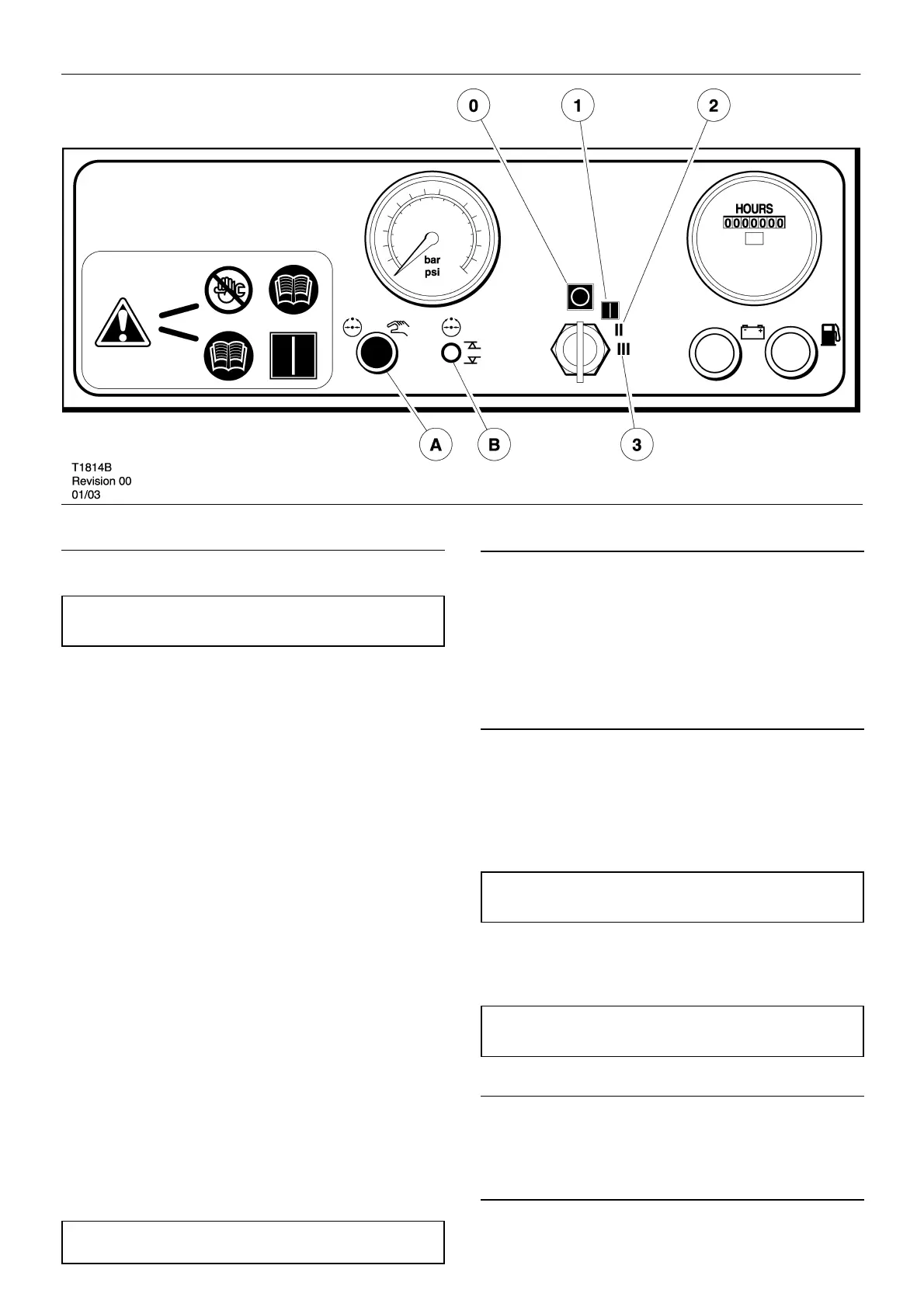

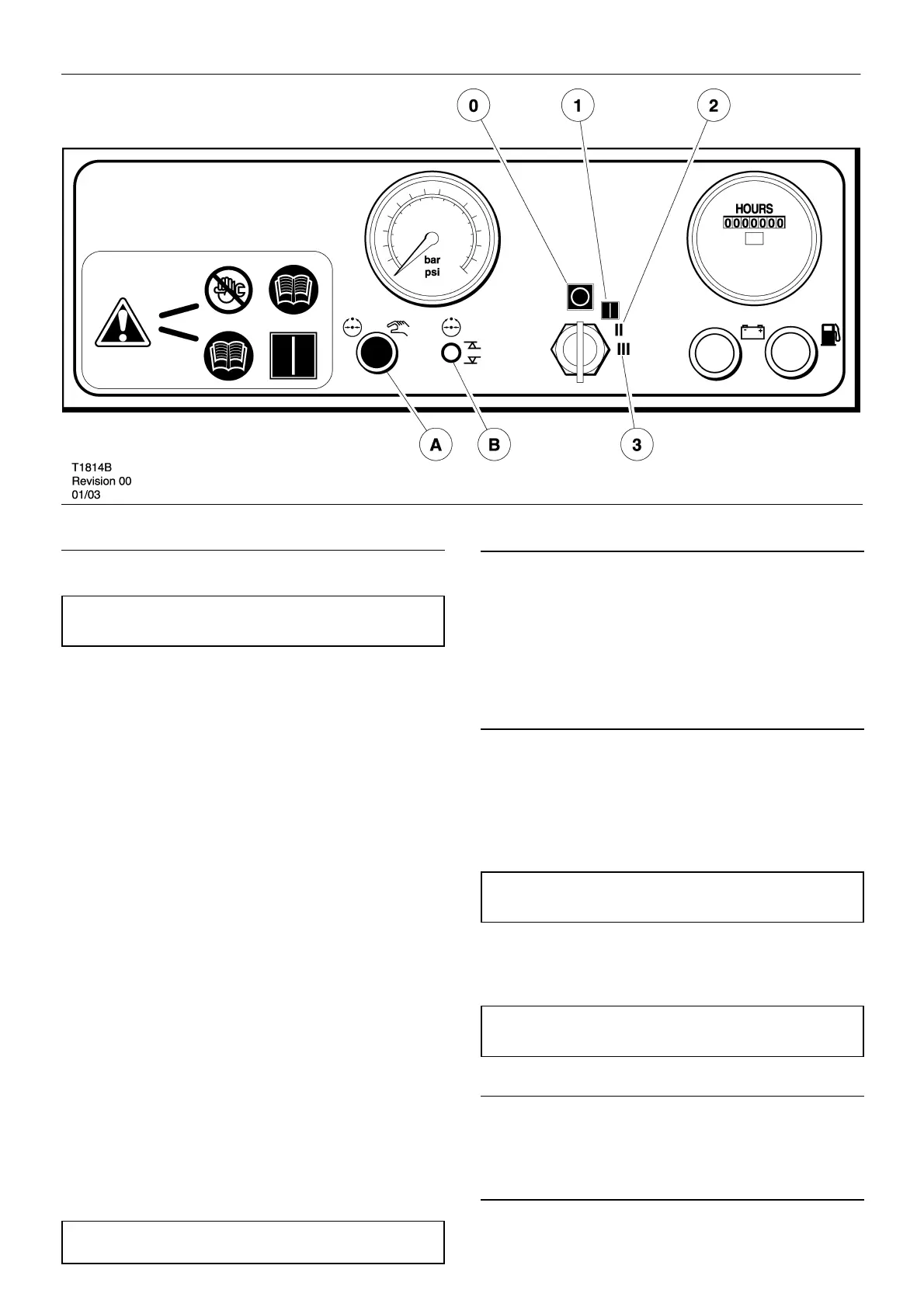

STARTING THE MACHINE

WARNING: Under no circumstances should volatile liquids such

as Ether be used for starting this machine.

All normal starting functions are incorporated in the key operated

switch.

. Turn the key switch to position 3 (engine start position).

. Release to position 2 when the engine starts.

. Release to position 1 when the alternator charge light is

extinguished.

At temperatures below 0C or if there is difficulty starting first time:

. Open the service valve fully, with no hose connected.

. Complete starting sequence above.

. Close service valve as soon as engine runs freely.

. Do not allow machine to run for long periods with service valve

open.

. Allow the engine to reach its operating temperature − then press the

button (A).

. At this point in the operation of the machine it is safe to apply full load

to the engine.

NOTE: Wear hearing protection at all times when the engine is started

with the service valve open and air is flowing from the valve.

DUAL PRESSURE WHEN FITTED

Machines which operate in excess of 7 bar can optionally be fitted with

a dual pressure switch (B). This switch selects between 7 bar and the

machine rated pressure, cfm remains nominally constant.

Starting and stopping are unaffected by the selection and during normal

running the selector switch may be safely operated. Precaution must

be taken to ensure that downstream equipment is rated to suit the

available pressure.

The pressure guage indicates which setting has been selected.

STOPPING THE MACHINE

. Close the service valve.

. Allow the machine to run unloaded for a short period of time to

reduce the engine temperature.

. Turn the start switch to the 0 (off) position.

NOTE: As soon as the engine stops, the automatic blowdown valve will

relieve all pressure from the system.

If the automatic blowdown valve fails to operate, then pressure must

be relieved from the system by means of the service valve(s).

CAUTION: Never allow the machine to stand idle with pressure in the

system.

EMERGENCY STOPPING

In the event that the unit has to be stopped in an emergency, TURN

THE KEY SWITCH LOCATED ON THE INSTRUMENT PANEL TO

THE 0 (OFF) POSITION.

RE−STARTING AFTER AN EMERGENCY

If the machine has been switched off because of a machine

malfunction, then identify and correct the fault before attempting to

re−start.

Loading...

Loading...