56

PERIODICAL INSPECTION AND MAINTENANCE.

7/71, 12/56

Cooling System Circuit Cleaning

When the cooling system circuit is contaminated with water scales or

sludge particles, cooling efficiency will be lowered. Periodically clean

the circuit interior with a suitable cleaner.

Clean the cooling system circuit every 1000 operating hours or 12

months, whichever comes first.

FUEL SYSTEM

The fuel injection pump and injector nozzles are precisely

manufactured, and therefore, using fuel which contains water or dust

particles will result in either injection pump plunger seizure or injector

nozzle seizure. A fuel filter element blocked with sludge or dust

particles will lead to reduced engine output.

Perform inspection and maintenance periodically as follows:

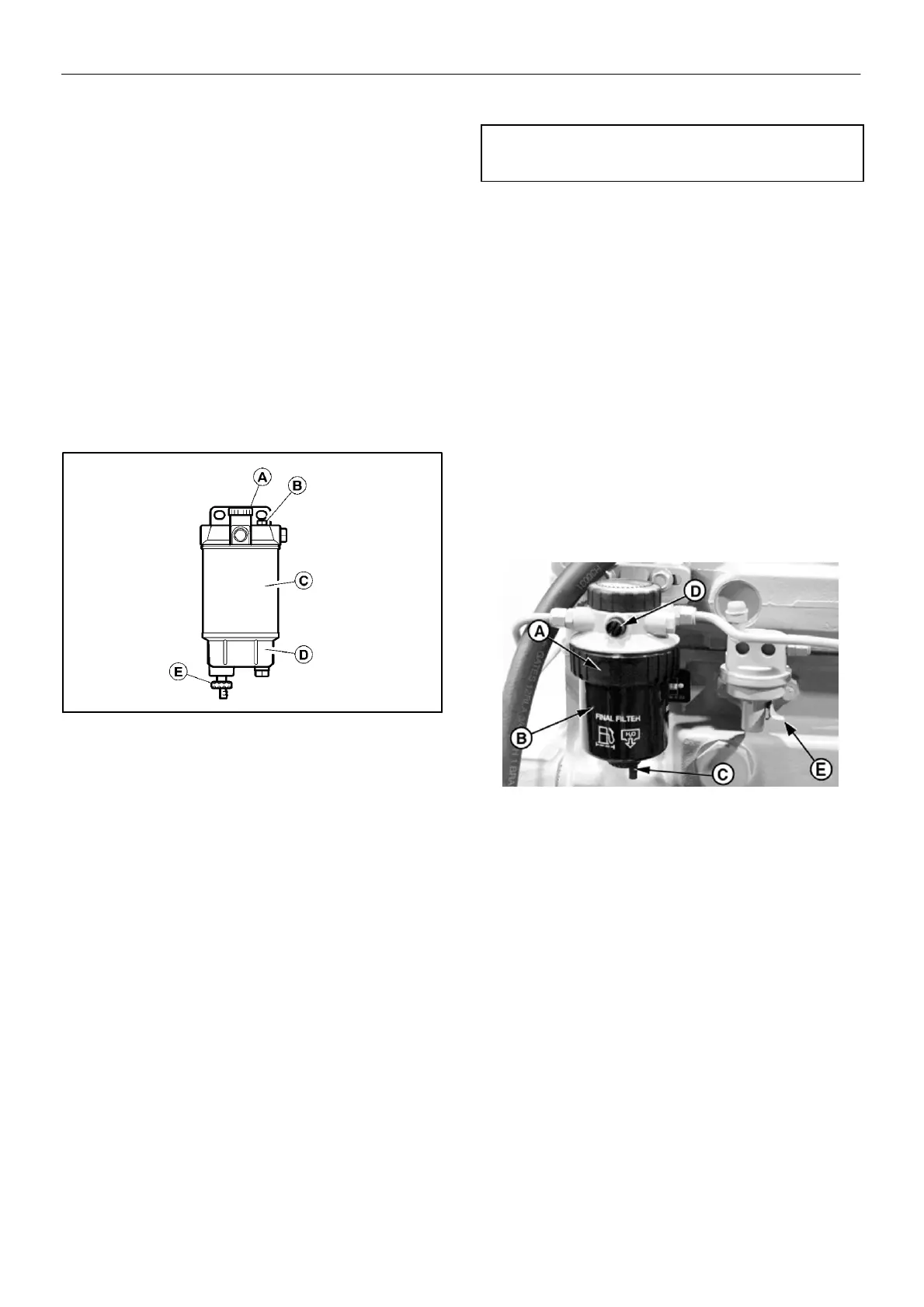

Fig. 15

A Primer pump head

B Vent plug

C Filter element

D Clear bowl

E Drain valve

Draining Water from Fuel Filter/separator.

The fuel filter/separator is provided to allow water to be drained from the

fuel system. Water is heavier than fuel so any water contained in the

system will collect in the bottom of the bowl.

The clear bowl ‘D’ should be checked on a daily basis and if water is

present, it should be drained from the separator.

Place a suitable container under the separator to prevent any spillage

inside the machine.

Slacken the drain valve ‘E’ until water drains from the vent tube.

When all the water has been evacuated, tighten the drain valve ‘E’ and

follow the “fuel system air bleeding” procedure below.

Fuel filter/separator element change.

NOTE:

The cartridge and bowl contain fuel. Take care not to spill it during

disassembly and reassembly.

The fuel filter/separator also provides primary filtration and the element

‘C’ should be changed every 500 operating hours or 6 months,

whichever comes first.

Change procedure:

Unscrew the element ‘C’ from the head taking care not to spill fuel

inside the machine. Drain any fuel within into a suitable container, then

unscrew the clear bowl ‘D’ from the element.

Discard the old element into a suitable container.

Remove the old ‘O’ ring from the bowl ‘D’ and install the new one

supplied with the element. Apply a light coat of clean engine oil to the

‘O’ ring and screw the bowl ‘D’ onto the new element ‘C’.

Using a clean cloth, wipe the sealing face of the filter/separator head

to ensure correct seating of the sealing ring.

Fill the element/bowl assembly with clean fuel oil then apply a light

coat of clean engine oil to the new element seal ring.

Screw the new element onto the head firmly by hand.

Follow the “fuel system air bleeding” procedure below.

Secondary fuel filter

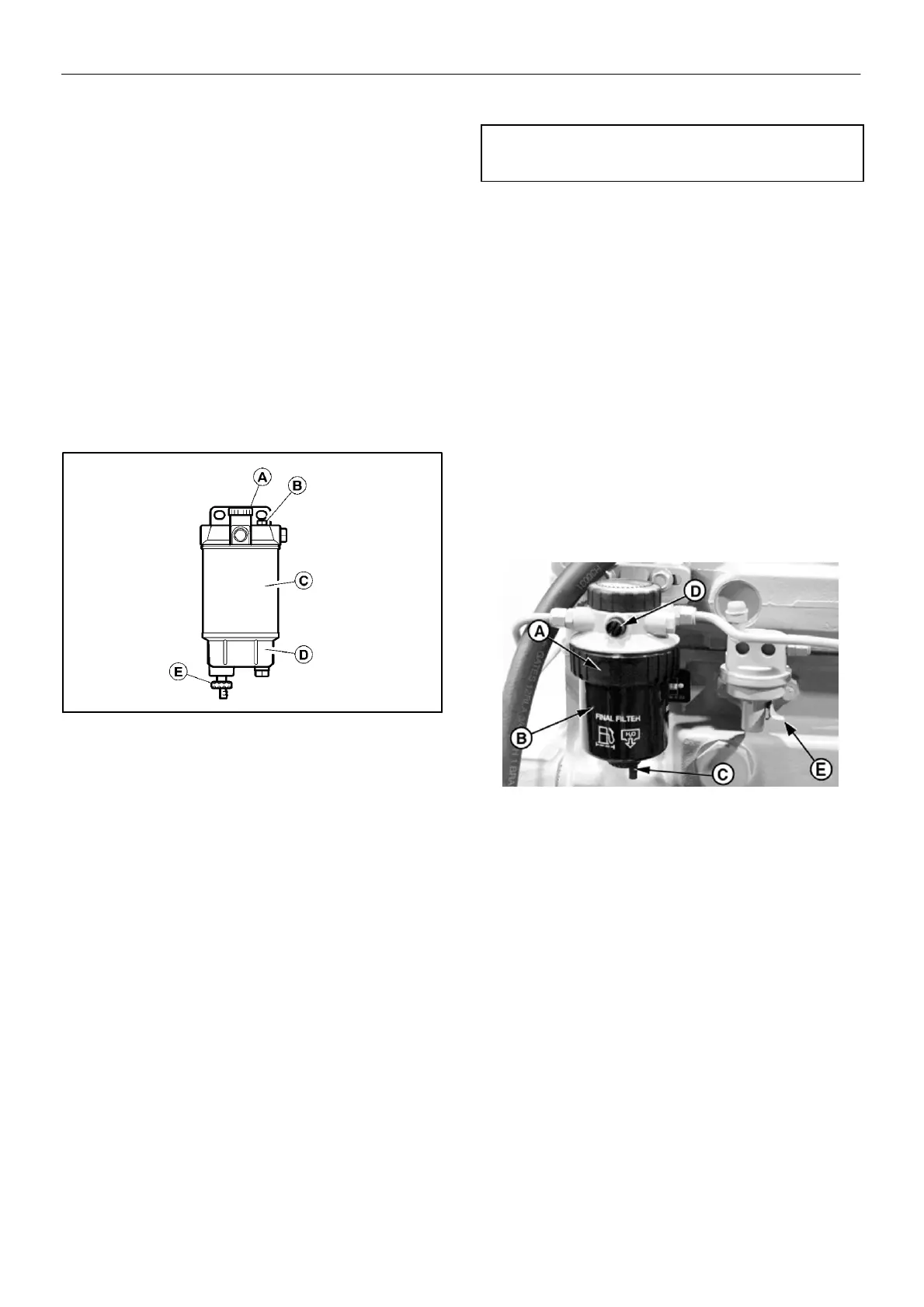

Fig. 16

A Retaining ring

B Cartridge element

C Drain plug

D Bleed plug

E Hand priming lever

The element should be changed every 500 operating hours or 6

months, whichever comes first

Change procedure:

Clean area surrounding fuel filter base.

Loosen drain plug C and empty fuel into suitable container.

Rotate retaining ring A counterclockwise

1

/

4

turn.

Remove ring and filter cartridge B together.

Install new filter cartridge inside ring and fit to base.

(Note: Top of cartridge has locators which must align with slots in the

base.)

Loading...

Loading...